Agilent Corporate Citizenship Report 2013

DMA EN

DISCLOSURE ON MANAGEMENT APPROACH EN

Agilent is committed to conducting its business in

an ethical, socially responsible, and environmentally

sustainable manner by reporting performance and

ensuring that production and operations meet or exceed

relevant environmental legislation and regulations.

We operate under a company-wide Environmental,

Health and Safety Management System (EHSMS) that

applies to our design, development, manufacturing,

distribution, and sales and service operations worldwide.

Agilent has demonstrated its effectiveness in managing

environmental impact by maintaining an ISO 14001

registration of our EHSMS. EHSMS is a tool to drive

continual improvement in environmental performance

and pursuit of sustainability. We expect our suppliers

to adhere to the same standard of environmental and

social responsibility that we maintain, and our Supplier

Environmental and Social Responsibility Code of Conduct

requires suppliers to adopt sound environmental, health,

and safety management practices.

Agilent Supplier Code of Conduct

Agilent is committed to designing, manufacturing, and distributing environmentally responsible products. Environmental aspects are considered in the design, manufacture, distribution, use, obsolescence, disposal, recovery, and reuse of Agilent products. Our aim is to minimize environmental impact of our products and operations by conforming to applicable regulations.

Agilent has developed an Environmental Compliance Framework to sustain and facilitate compliant product design, development, production, refurbishment, and support. When a customer no longer requires an Agilent product, we have implemented several options for reuse, remanufacture, or take-back based on the product type and customer location to ensure the product is properly managed. Additional information on our environmental and social performance may be found at Agilent's Commitment to Environment and Social Responsibility.

Agilent recognizes ISO 26000 as a reference document that provides guidance on social responsibility. Agilent aligns with ISO 26000 standards as part of our social responsibility practices. As such, Agilent's environmental policies, programs, and procedures align with ISO core subjects: Environment 6.5 and Organizational Governance 6.2.

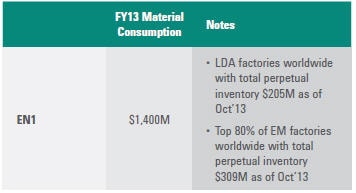

EN1

MATERIAL USED BY WEIGHT OR VOLUME

Currently we are unable to report material used by weight

or volume. We will report cost of material consumption

until we are able to report material usage by weight

or volume.

EN2

PERCENTAGE OF MATERIALS USED THAT ARE RECYCLED INPUT MATERIAL

We do not currently report this data; we are investigating

automated ways to collect this information.

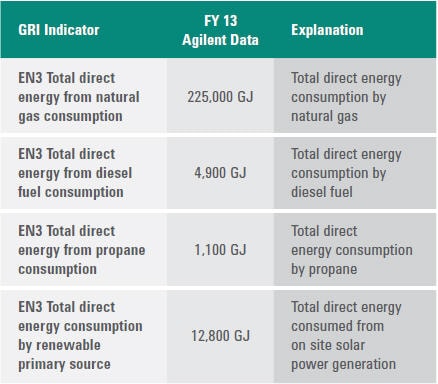

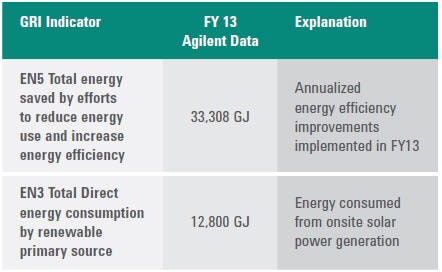

EN3

DIRECT ENERGY CONSUMPTION BY PRIMARY ENERGY SOURCE

(The data provided for energy and water has been attested by TruCost)

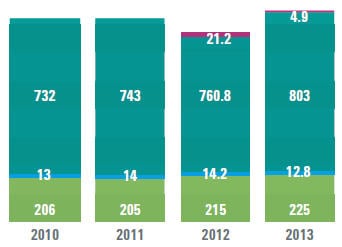

Worldwide energy consumption 20131

|

|

Notes: 1 US Energy Information Agency International Electricity Emissions Factor by Country, 1999–2002 were utilized for all non-U.S. facilities. 2012 Defra (UK Department of Environment, Food and Rural Affairs) factors were used to calculate emissions from stationary fuel consumption.

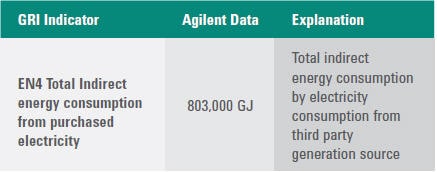

EN4 INDIRECT ENERGY CONSUMPTION BY PRIMARY SOURCE

1 For FY13data—EPA eGRID2012 Version 1.0 included 2009 emissions factors for CO2, CH4 and N20 used to calculate CO2 equivalent emissions from electricity consumption for U.S. facilities.

EN5 ENERGY SAVED DUE TO CONSERVATION AND EFFICIENCY IMPROVEMENTS

EN6 INITIATIVES TO PROVIDE ENERGY-EFFICIENT OR RENEWABLE ENERGY BASED PRODUCTS AND SERVICES, AND REDUCTIONS IN ENERGY REQUIREMENTS AS A RESULT OF THESE INITIATIVES

Agilent is working on improving the energy efficiency of selected products/product families compared to the predecessor models. Product families selected included instruments with high energy consumption.

Agilent has worked on assessing energy efficiency of several types of products by using customer base metrics. By identifying energy-using features, we are able to increase energy efficiency of our products. During the past several years, Agilent has moved toward product energy efficiency in several product lines. Most of the energy savings are due to two key factors:

- The increased type and volume of tests that can be conducted, thus increasing tests per watt.

- Enhanced existing product features, thus bringing more measurement capabilities to the same product footprint.

Agilent's concentration on handheld and portable instruments places a focus on energy efficiency:

- Next-generation products are using key new technology that greatly improves performance per watt of power supply.

- Portable products put significant design efforts into power management to achieve power, heat, and battery life targets.

- Industry and regulatory requirements on the power supplies for our portable products have also increased power supply efficiency.

EN7 INITIATIVES TO REDUCE INDIRECT ENERGY CONSUMPTION AND REDUCTIONS ACHIEVED

Energy and water conservation initiatives were implemented worldwide across Agilent. These initiatives include capital and operational improvements that range from constructing new energy-efficient facilities; decommissioning underutilized and less efficient buildings and spaces; re-commissioning existing building systems for current uses; and optimizing equipment operations. Our combined efforts helped us exceed our FY13 energy conservation goal.

A new energy-efficient data center was constructed at Agilent's Colorado Springs campus, increasing the data handling capacity while reducing energy consumption. The campus also refurbished its buildings' heating, ventilation, and air-conditioning systems. The buildings now adjust to the heating and cooling dmands based on changes in occupancy while still maintaining comfort and safety standards. Collectively, these initiatives reduce energy consumption by 4.3 million kWh and emissions by 2,240 tons CO2-equivalent. In addition, a portion of the campus's landscaping was transformed into xeriscaping to decrease the amount of water used to irrigate the area.

The Agilent China campus in Chengdu retrofitted its cooling tower system, improved water-level controls in its fire prevention basin, and upgraded lighting. The need for make-up water in the cooling system was reduced by recirculating the water being used. Laser level sensors were added to the fire prevention basins to maintain water levels while eliminating overflow. Evacuation signs, which are illuminated 24 x 7, were replaced with LED versions.

Energy efficiency was designed into a new R&D building constructed at Agilent's Mulgrave campus in Australia. Above-standard lighting efficiency was achieved by using LED and T5 fixtures. Occupancy sensors were also installed to control the lighting. Overall, the lighting design and control conserves 127,899 kWh of electricity consumption annually compared with using T8 fixtures without lighting controls, and it avoids 109 tons CO2 equivalent emissions. In addition, the potential heat gain of the building was reduced by adding a veil to the façade, which reduces energy consumed to cool the interior space.

An innovative humidification system was implemented in one of the buildings at Agilent's Waldbronn facility in Germany. The site capitalized on the narrow characteristics of the building to simultaneously reduce energy and water consumption through the use of a decentralized humidification system. The system maintains humidity levels through micro-fine atomization without compressed air, steam or ultrasound. This effort conserves 228,165 kWh of energy as well as 3,900 gallons of water annually.

Our net energy conservation for FY13 (for sites included in this report) was 3.22% percent (using FY12 total energy spend as a baseline).

EN8 TOTAL WATER WITHDRAWAL BY SOURCE

- Total volume of water from water utilities (1000 m3) = 1,194.175

- Wastewater purchased from other organizations includes 58,685 m3 of “NEWater,” purchased at the Singapore site which is reclaimed water produced by the local water board. It consists of wastewater that has gone through water-treatment processes including purification and UV technology. This amount is included in the “water withdrawn” totals below.

- Water withdrawn from water utilities per region

? (1,000 m3):

? Asia Pacific - 667.285

? Europe - 44.431

? USA - 482.459

EN9

WATER SOURCES SIGNIFICANTLY AFFECTED BY

WITHDRAWAL OF WATER

Most of our manufacturing sites' water comes directly

from the city water supply. However, the following sites

draw some water from the local aquifer: Manesar, India;

Torino, Italy; Hachioji, Japan; Santa Rosa, USA. Of those

sites, Manesar, India is the only site considered to have

a water source potentially affected by withdrawal of

water. Water withdrawal at Manasar was 39.270 m3

during FY13.

EN10

PERCENTAGE AND TOTAL VOLUME OF WATER RECYCLED

AND REUSED

The only site that currently uses recycled water is Santa

Rosa, USA, which has an onsite wastewater treatment

facility. During the reporting period, the Santa Rosa site

recycled 75.22 (1,000m3) water, or 37% of the total annual

consumption of the site.

EN11

LOCATION AND SIZE OF LAND OWNED, LEASED, MANAGED

IN, OR ADJACENT TO, PROTECTED AREAS AND AREAS OF

HIGH BIODIVERSITY VALUE OUTSIDE PROTECTED AREAS.

Not applicable. Agilent manufacturing sites are not

located in protected areas or areas of high biodiversity

value.

EN12

DESCRIPTION OF SIGNIFICANT IMPACTS OF ACTIVITIES,

PRODUCTS, AND SERVICES ON BIODIVERSITY IN PROTECTED

AREAS AND AREAS OF HIGH BIODIVERSITY VALUE OUTSIDE

PROTECTED AREAS.

Not applicable. Agilent manufacturing sites are

not located in protected areas or areas of high

biodiversity value.

EN13

HABITATS PROTECTED OR RESTORED.

Not applicable. Agilent manufacturing sites are not

located in habitat-protected areas or restored areas.

EN14

STRATEGIES, CURRENT ACTIONS, AND FUTURE PLANS FOR

MANAGING IMPACTS ON BIODIVERSITY.

Not applicable. Agilent manufacturing sites are not

located in habitat-protected areas or restored areas.

Not applicable. Agilent manufacturing sites are not located in habitat-protected areas or restored areas that could potentially be endangered or threatened.

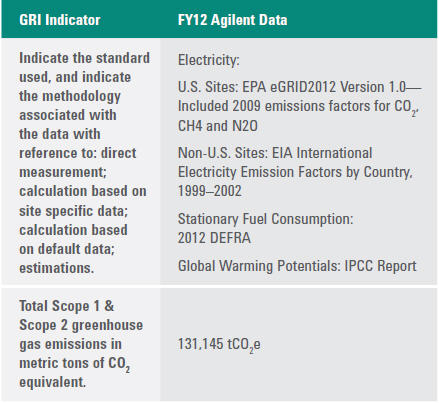

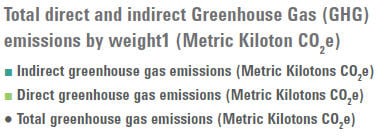

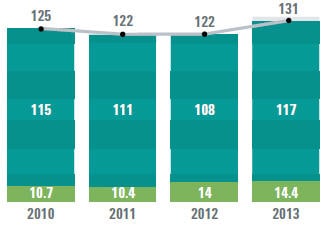

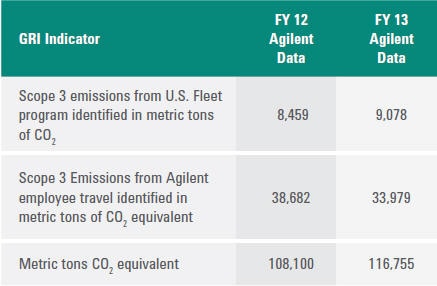

EN16 TOTAL DIRECT AND INDIRECT GREENHOUSE GAS EMISSIONS BY WEIGHT

Notes: 1 For FY 13 data emissions refer to EN 16 table.

EN17 OTHER RELEVANT INDIRECT GREENHOUSE GAS EMISSIONS BY WEIGHT

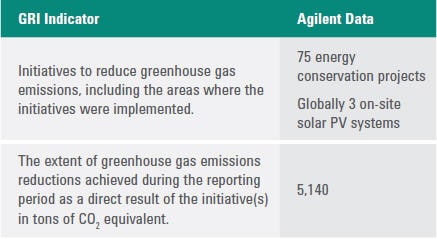

EN18 INITIATIVES TO REDUCE GREENHOUSE GAS EMISSIONS AND REDUCTIONS ACHIEVED

EN19

EMISSIONS OF OZONE-DEPLETING SUBSTANCES BY WEIGHT.

There was no ODC usage at our sites.

EN20

NOX, SOX, AND OTHER SIGNIFICANT AIR EMISSIONS BY

TYPE AND WEIGHT.

Currently we are unable to report on these numbers.

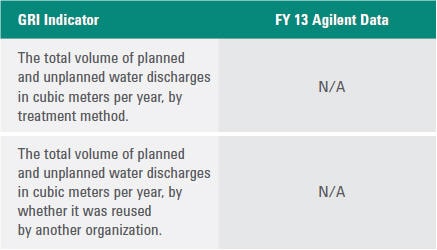

EN21 TOTAL WATER DISCHARGE BY QUALITY AND DESTINATION

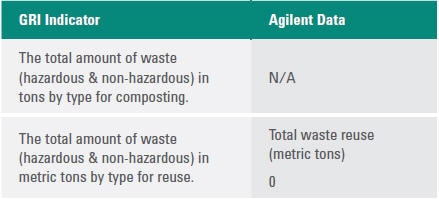

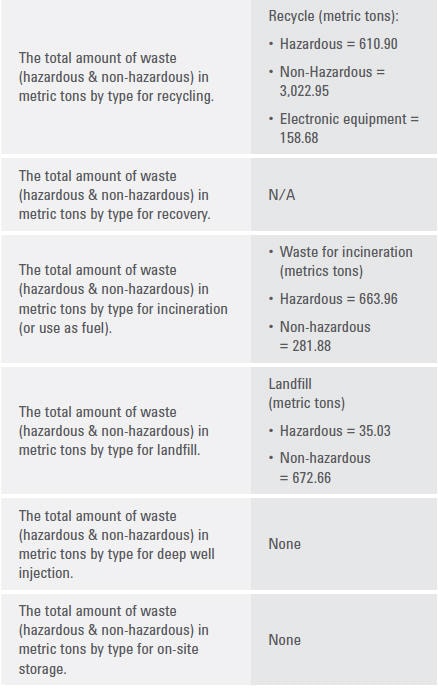

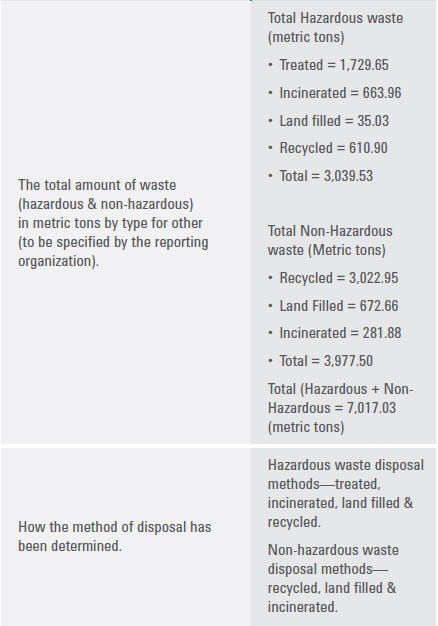

EN22 TOTAL WEIGHT OF WASTE BY TYPE AND DISPOSAL METHOD

Notes:

1 Total waste produced is calculated by adding total chemical waste and

total solid waste tonnage. Total waste calculated based on calendar

year (January 2013 – December 2013).

2 Chemical waste refers to chemical materials designated for final

disposition that exhibit characteristic that is hazardous or dangerous

per local regulatory requirements. This refers to materials that are

shipped offsite for treatment, recycling, incineration, and landfill; and

excludes electronic waste.

3 Solid waste refers to waste that is not included in chemical waste or

excess electronic equipment (e.g., garbage/trash, paper, cardboard,

glass, and furniture and construction debris).

Electronic Equipment is personal computers, computer monitors, misc electronic test & manufacturing equipment, obsolete electronic equipment, telephones, and spare or unused products from manufacturing.

Electronic equipment - reused: electronic equipment sold or given to third party organizations such as charitable organizations or used equipment resellers. Agilent cannot guarantee that this equipment is re-used or resold. Agilent requires that equipment resellers dispose of any unsold electronic equipment according to state and local legal requirements.

Electronic equipment - recycled: electronic equipment that is sent directly to an electronic recycler with the intent of recycling the equipment's components, sub-components, or material (e.g. precious metals). Agilent requires that recyclers dispose of all electronic equipment, components, and subcomponents according to state and local legal requirements.

EN23

TOTAL NUMBER AND VOLUME OF SIGNIFICANT SPILLS

In FY13 there were no significant spills

EN24

WEIGHT OF TRANSPORTED, IMPORTED, EXPORTED, OR

TREATED WASTE DEEMED HAZARDOUS UNDER THE TERMS

OF THE BASEL CONVENTION ANNEX I, II, III, AND VIII,

AND PERCENTAGE OF TRANSPORTED WASTE SHIPPED

INTERNATIONALLY

Not applicable. Currently we do not have any transboundary

waste shipment, under the Basel Convention.

EN25

IDENTITY, SIZE, PROTECTED STATUS, AND BIODIVERSITY

VALUE OF WATER BODIES AND RELATED HABITATS

SIGNIFICANTLY AFFECTED BY THE REPORTING

ORGANIZATION'S DISCHARGES OF WATER AND RUNOFF

No value of water bodies and related habitats are

impacted by any discharges of water or runoff by

Agilent's operations.

EN26

INITIATIVES TO MITIGATE ENVIRONMENTAL IMPACTS

OF PRODUCTS AND SERVICES, AND EXTENT OF IMPACT

MITIGATION

Initiatives to mitigate the most significant environmental

impacts of products/service groups:

- Agilent continued to make significant progress toward complying with EU Restriction of Hazardous Substances (RoHS). Agilent's Electronic Measurement Group (EMG) now has more than 2,000 products designed to be compliant with EU RoHS and Agilent's Life Sciences and Diagnostics and Chemical Analysis Groups have now introduced their first product designed for RoHS compliance. These achievements are three years ahead of the 2017 regulatory deadline for Test and Measurement products. This effort has had positive implications on Agilent's materials use, regulatory compliance, waste impacts and customer satisfaction.Agilent's supplier code of conduct ensures compliance with Environmental, Health, Safety, and Social Responsibility guidelines throughout our supply chain. Our suppliers are also accountable for ensuring that their subcontractors also comply with Agilent's EHSSR guidelines, with responsibility for taking corrective action as necessary.

- Agilent includes a corporate citizenship overview in all new employee orientation, ensuring that social and environmental responsibility will continue to be a part of our culture moving forward.

- Agilent implemented due diligence practices following the EICC standard to meet requirements of the Dodd- Frank Wall Street Reform and Consumer Protection Act commonly known as conflict minerals. Our actions will result in meeting annual reporting requirements to the Securities Exchange Commission. Agilent's supplier code of conduct was updated to include the expectation that “Suppliers shall take reasonable measures to ensure products, parts, components and materials supplied to Agilent are “DRC (Democratic Republic of Congo) conflict free” as that term is used under Section 1502 of the Dodd-Frank Act.

- Agilent continued its robust communication of our General Specification for the Environment (GSE) with its strategic suppliers. This effort enables Agilent and its suppliers to comply with major environmental regulations on material use, product packaging, and labeling. The most significant change in this revision is the incorporation of new requirements resulting from the European REACH regulation additions regarding substances of very high concern and regulations on F-Gases.

- Agilent established targets to reduce water consumption by 10 percent in the next 3 years to reduce impact on environment and natural resources.

EN27 PERCENTAGE OF PRODUCTS SOLD AND THEIR PACKAGING MATERIALS THAT ARE RECLAIMED BY CATEGORY

- Agilent's Remarketing Solutions Division is dedicated to recovering older instruments for the purpose of resale. For a certain segment of our customers (startups, academics, etc.), these pre-owned instruments offer a competitively priced alternative to buying a new instrument. As a company, we are using fewer environmental resources to manufacture new products to meet this customer demand. For More Detail, Premium Refurbished Instruments.

- Agilent offers a variety of trade-in programs specifically designed to help customers safely dispose of or recycle used instrumentation. The program is currently deployed in several countries, with expansion of these programs being considered wherever possible.

EN28 MONETARY VALUE OF SIGNIFICANT FINES AND TOTAL NUMBER OF NON-MONETARY SANCTIONS FOR NONCOMPLIANCE WITH ENVIRONMENTAL LAWS AND REGULATIONS

- In FY13, Agilent reported a total of 29 alleged regulation compliance violations. However, only one incident resulted in a monetary fine ($802). This occurred at the Shanghai, China site.

<< Economic Performance

Social : Labor Practices and Decent Work Indicators >>