Access Agilent eNewsletter September 2016

Gain control—Agilent 490-PRO Micro GC optimizes process monitoring

Coen Duvekot

Agilent Product Manager, Micro GC

Remko van Loon

Agilent GC Applications Specialist

To effectively monitor and control processes, many companies need fast, precise, reliable, unattended gas analysis. The Agilent 490-PRO Micro GC is designed for this purpose and delivers results in just seconds. It is ideal for applications that require unattended, round-the-clock measurements. These applications include natural gas analysis/calorific value determination, biogas analysis, bulk and trace analysis of refinery or stack gas, and trace analysis of sulfur.

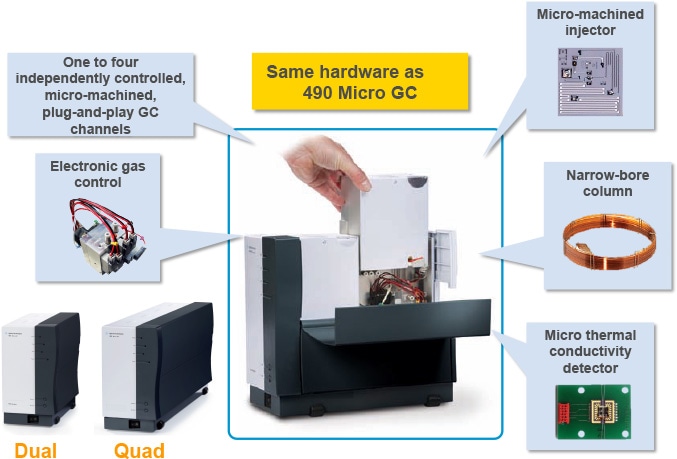

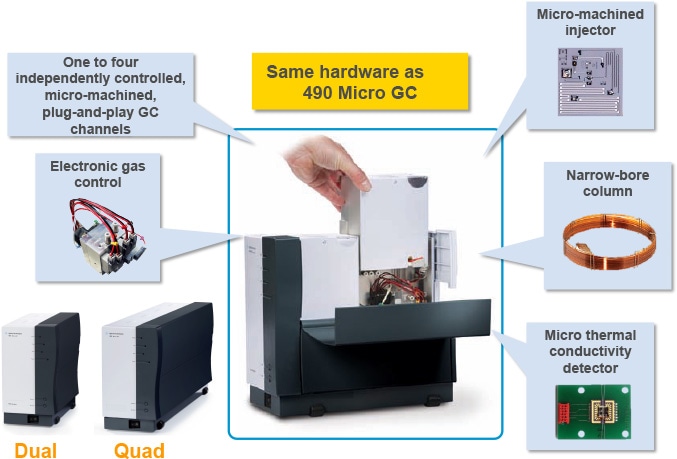

Figure 1. Agilent 490-PRO Micro GC is a fast, high-performance gas measurement platform designed for unattended operation.

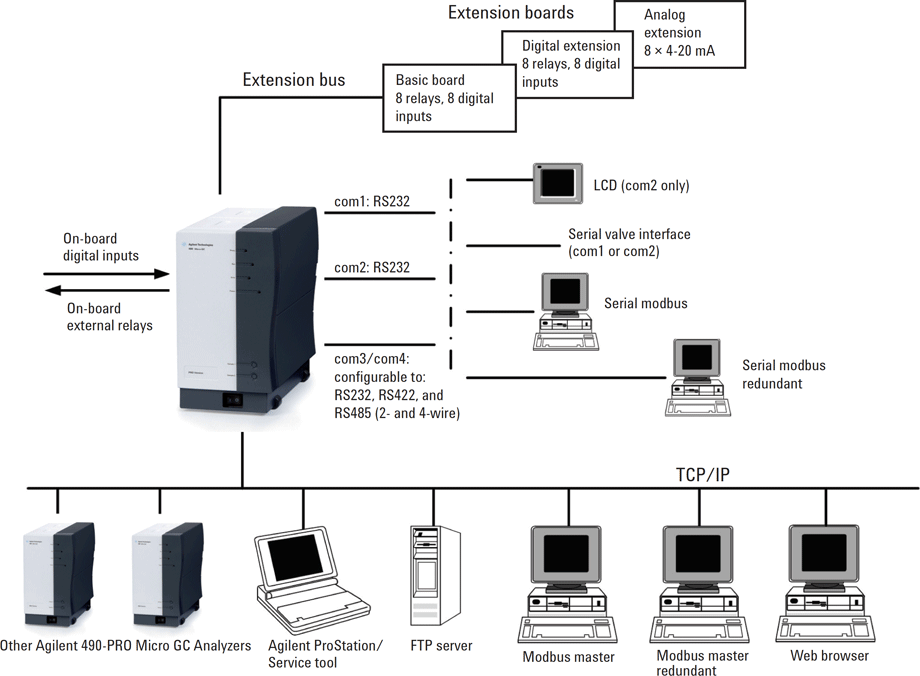

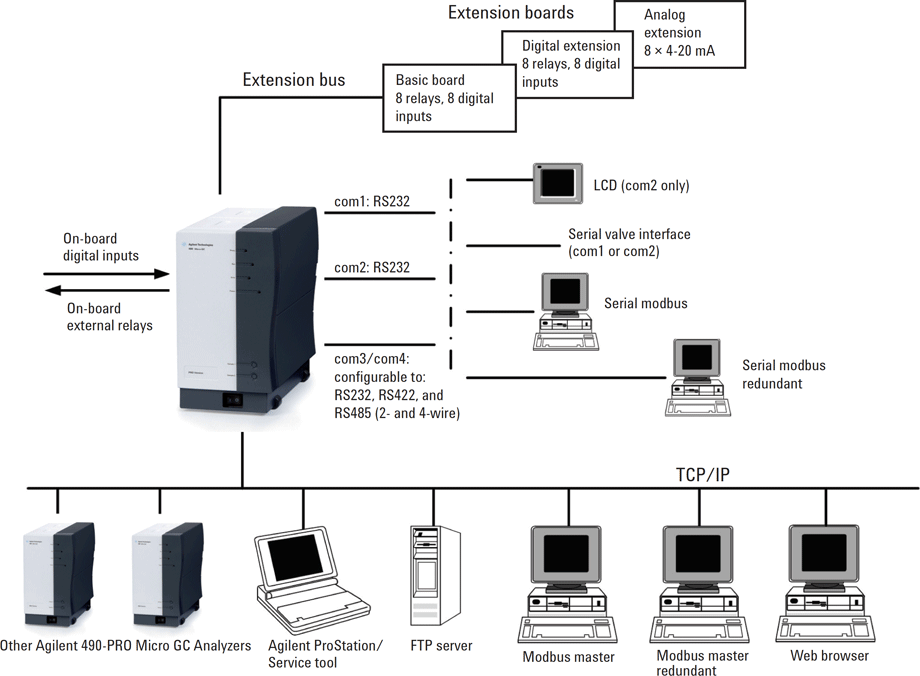

Figure 2. Agilent 490 Micro GC rapidly delivers the information you need in a process environment.

Measure anywhere—for quick process optimization

Key benefits of the system include:

- Repeatable, fast, and accurate monitoring.

- In-board data handling so no local operator is needed. The Agilent 490-PRO Micro GC offers data collection, data integration, and result transfer via industrial communication protocols, so you quickly and accurately monitor and control processes.

- Added convenience with on-line/at-line analysis, using the 490-PRO Micro GC configured in an optional 19-inch rack.

- For safety, the Agilent 490-PRO Micro GC does not use flammable gases, and requires only small quantities of sample gas for analysis and monitoring.

Autonomous system quickly delivers the results you need

Agilent Application Note 5991-1817EN describes use of the Agilent 490-PRO Micro GC for the analysis of liquefied ethane product. The ethane stream analysis requires the detection of nitrogen, methane, carbon dioxide, ethane, and propane, with trace detection of hydrogen sulfide and methanol. The 490-PRO Micro GC uses a single 10-m PoraPLOT Q column channel to analyze all components of interest in only 180 seconds. Results are calculated by the on-board data handling and calculation module and delivered to plant processing and pipeline operating systems.

The Agilent 490-PRO Micro GC, designed to be a system component, does not require a connection with a chromatography data system to generate data and results. It features on-board data collection, peak integration, and result calculation. The powerful Agilent PROstation set-up tool was used to program these method parameters in the 490-PRO Micro GC. After setup, PROstation was disconnected and user-defined analysis results and information were automatically passed to an external system in an unattended manner.

Three different sample streams, two product streams, and one calibration mixture were coupled to the 490-PRO Micro GC. This setup featured scheduled and fully automated calibration verification, as well as any required instrument recalibration.

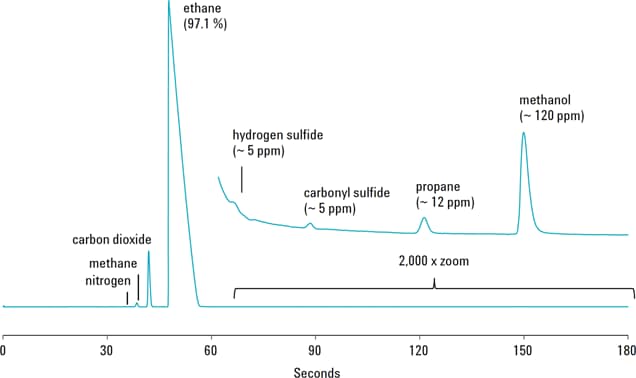

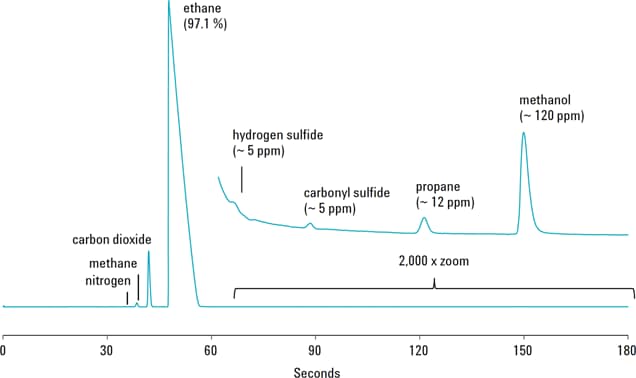

Figure 3. Chromatogram for ethane product on a 10-m PoraPLOT Q column channel show baseline separation for all compounds of interest.

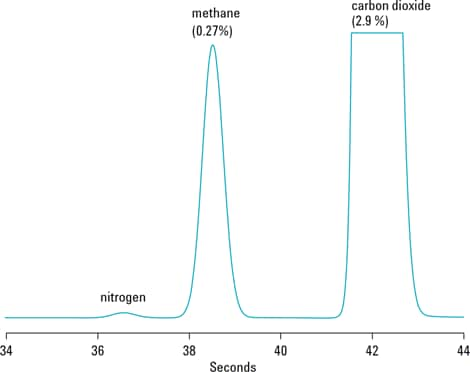

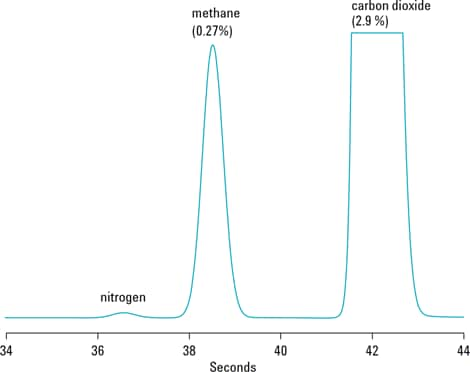

Figure 4. Chromatogram showing nitrogen and methane separation.

Single run for both bulk ethane composition and low-level impurity analysis

The Agilent 490-PRO Micro GC, equipped with a single 10-m PoraPLOT Q column channel, analyzed ethane composition and its low-level impurities in a single run. Detection of trace components to ppm levels was possible through the use of the auto ranging feature of the micro thermal conductivity detector (µTCD). This functionality enabled automatic switching from ultra-high sensitivity (low ppm range) to normal settings (percentage levels).

Characterization of the ethane product requires analysis of nitrogen, methane, carbon dioxide, ethane, and propane. Impurity analysis includes hydrogen sulfide and methanol characterization. Chromatograms of an ethane sample stream are displayed in Figure 3 and Figure 4 and they show good separation for all compounds of interest.

Excellent accuracy for more than one million injections over five years

For another gas analysis, Agilent Application Note 5991-1972EN shows that the Agilent 490-PRO Micro GC, equipped with an 8-m CP-Sil 5 CB column, successfully analyzes propane and butane streams in a process environment. The single-channel setup and low carrier gas consumption of the 490-PRO Micro GC also keep your investment and operating costs to a minimum.

This Agilent 490-PRO Micro GC system has maintained good accuracy and performance while completing more than one million injections in five years of operation (Table 1).

| Calibration at installation (%) | Verification at 2+ years (%) | Verification at 5+ years (%) | Precision at 5+ years (%) | |

|---|---|---|---|---|

| methane | 0.985 | 0.977 | 1.011 | 0.00051 |

| ethane | 4.800 | 4.806 | 4.833 | 0.00028 |

| propane | 89.780 | 89.794 | 89.806 | 0.00153 |

| i-butane | 2.140 | 2.131 | 2.129 | 0.00088 |

| n-butane | 1.260 | 1.270 | 1.241 | 0.00135 |

| i-pentane | 0.521 | 0.516 | 0.498 | 0.00005 |

| n-pentane | 0.514 | 0.507 | 0.483 | 0.00006 |

Table 1. Excellent long-term method performance over five years and one million injections.

The MEMS-based injector and detector, in combination with short and narrow-bore analytical columns, enable very fast analysis times. This example demonstrates baseline separation and detection of all compounds of interest in just one minute. Fast availability of sample composition enables more accurate trend display, better informed decisions, and faster process control.

Advance your process control

With the 490-PRO Micro GC, Agilent brings a lab quality analysis to an on-line/at-line application. Built-in on-board data handling and result generation take over the complete operation of the instrument. The system does not require a local operator; it runs standalone. For enhanced process control, all required results and information are automatically passed to external systems using industry-standard protocols.

If you need optimal process monitoring and control, explore more details about the Agilent 490-PRO Micro GC, then contact an Agilent representative to see how this instrument can streamline your process control.

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – September 2016

All articles in this issue

-

High-resolution, efficient quantification of aggregates in protein therapeutics with Agilent 1290 Infinity II 2D-LC Solution

High-resolution, efficient quantification of aggregates in protein therapeutics with Agilent 1290 Infinity II 2D-LC Solution -

Fast determination of bitter, clove-like flavor in beer with the Agilent 1290 Infinity II LC

Fast determination of bitter, clove-like flavor in beer with the Agilent 1290 Infinity II LC -

Direct heating delivers a new paradigm in gas chromatography analysis

Direct heating delivers a new paradigm in gas chromatography analysis -

Implementing an extractable and leachable (E&L) study from a pharmaceutical product by high resolution QTOF LC-MS

Implementing an extractable and leachable (E&L) study from a pharmaceutical product by high resolution QTOF LC-MS -

Multi-omic analysis helps researchers to integrate complex omics data in cancer research

Multi-omic analysis helps researchers to integrate complex omics data in cancer research -

Gain control—Agilent 490-PRO Micro GC optimizes process monitoring

Gain control—Agilent 490-PRO Micro GC optimizes process monitoring

Figure 1

Agilent 490-PRO Micro GC is a fast, high-performance gas measurement platform designed for unattended operation.

Figure 2

Agilent 490 Micro GC rapidly delivers the information you need in a process environment.

Figure 3

Chromatogram for ethane product on a 10-m PoraPLOT Q column channel show baseline separation for all compounds of interest.

Figure 4

Chromatogram showing nitrogen and methane separation.