Access Agilent eNewsletter April 2016

Oil-free laboratory vacuum eliminates oil mess and disposal costs

Roberto Cerruti, Agilent Global Marketing Manager, Instrumentation Vacuum

A crucial component of the GC/MS instrument is the vacuum system. All instruments equipped with a turbomolecular high vacuum pump require a forepump. Until recently, GC/MS users have not had an affordable alternative to the low-cost, oil-sealed rotary vane pump that has been the traditional device for this purpose. Oil-sealed pumps have inconvenient maintenance requirements, introduce the risk of spills, and may even cause contamination due to oil vapor migration. Diaphragm pumps, which are oil-free, are significantly more expensive alternatives that introduce an additional set of maintenance issues. The emergence of dry scroll pump technology presents a significant opportunity to simplify management of vacuum pumps, extend maintenance cycles, and eliminate oils.

Dry scroll pump operation explained

Dry scroll pumps consist of an orbiting rotor and a stator, with spiral channels machined into both surfaces. As the moving plate orbits, it traps a volume of gas and progressively compresses the gas into ever smaller volumes as the “involute” of gas is moved towards the center of the pump. Unlike rotary vane pumps, which use a film of oil to maintain gas tightness, dry scroll pumps use tight tolerances and sliding gaskets (“tip seals”) to prevent gas from migrating back towards the pump inlet.

Simplified, cost-effective maintenance

Diaphragm pumps require a full rebuild on “at least annual” basis, to prevent the possibility of a diaphragm rupture, which vents the foreline to atmosphere and potentially damages the turbo pump. Rebuilding a diaphragm pump is vastly more complex than a tip seal replacement.

Oil-sealed rotary vane pumps require that you remove, replace, and dispose of the oil whenever it becomes discolored—typically every 6 to 12 months depending on the application. Disposal cost for the used oil is a significant consideration.

The scroll pump requires replacement of two tip seals and a single o-ring after approximately one year of continuous use. This simple maintenance procedure is clean and can be accomplished in less than 30 minutes by anyone with modest mechanical skills. (See a video of tip seal replacement.)

Failure mode: predictable versus catastrophic

The wear-out of a diaphragm pump is not predictable, and typically maintenance is unplanned. In addition, unless a costly external shut-off valve is fitted, the failure mechanism of a diaphragm pump can have much greater consequences, such as irreparable damage to the turbo pump.

Rotary vane pumps typically fail through oil starvation or from blocked internal oil lubrication passages. While virtually all rotary vane pump manufacturers include an oil suck-back prevention device, these simple mechanisms are not completely fool-proof, and there are many documented cases of catastrophic oil migration back into the analyzer chamber.

As the tip seals wear on a scroll pump, the ultimate pressure that the pump can achieve slowly begins to rise. This rise is typically not observable by the GC/MS operator, and so may be managed easily through scheduled maintenance.

Positive shut-off valve prevents instrument damage

The Agilent IDP-3 Dry Scroll Pump model specified for field upgrades of Agilent GC/MS instruments includes a positive shut-off valve at the pump inlet. Operation of the valve is controlled by the pump to prevent any chance that foreign particles enter the foreline and cause damage to the instrument. When the pump is switched off (or a power outage occurs), the valve closes immediately, to maintain vacuum in the turbo pump foreline and to allow the instrument to shut down safely.

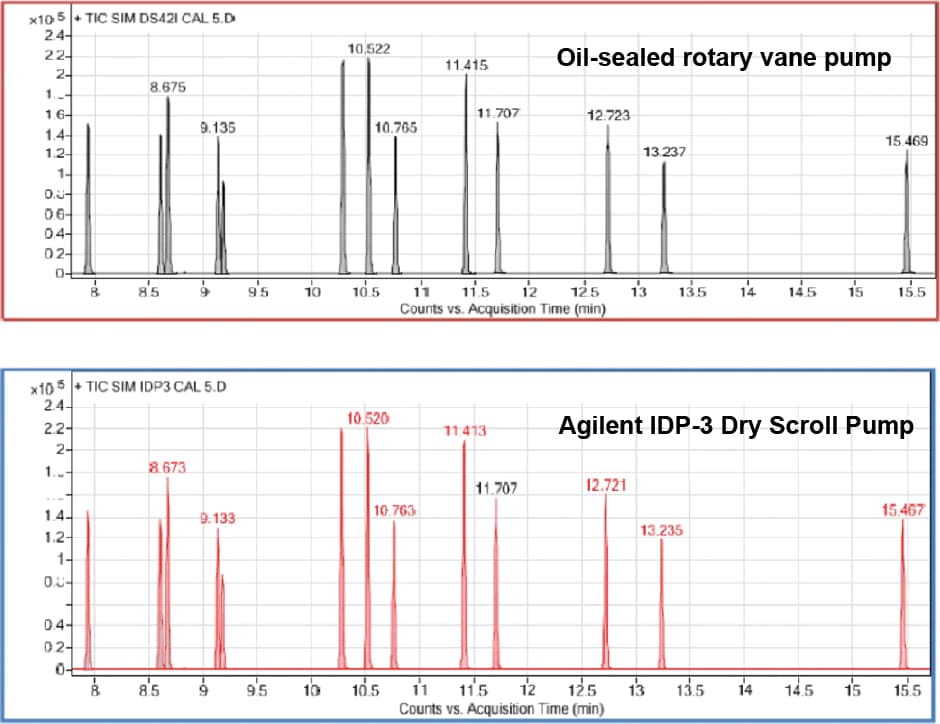

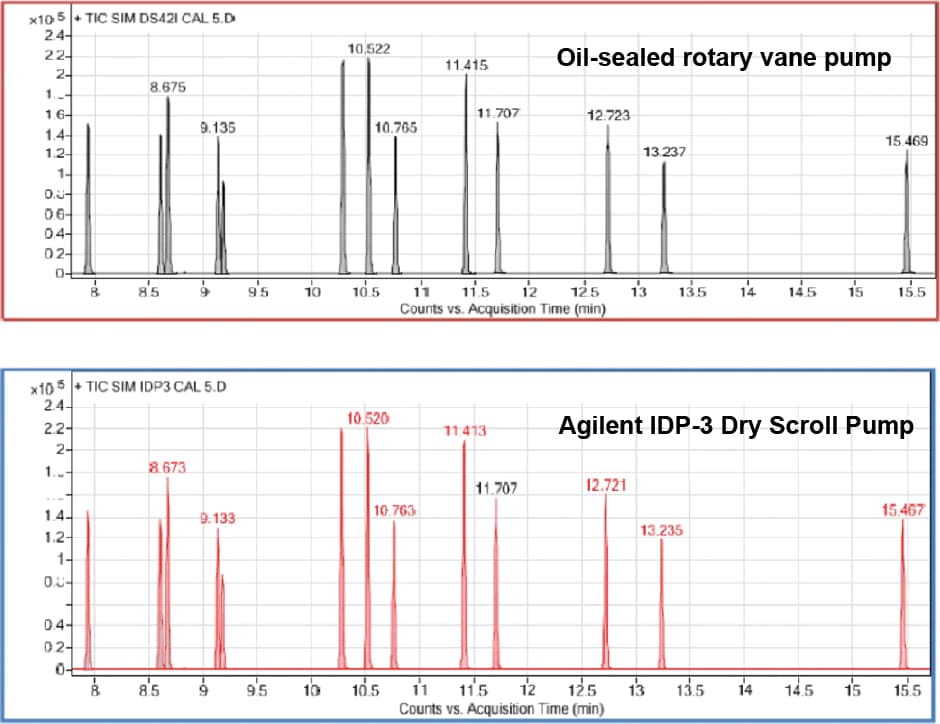

Figure 1. Mass assignments and relative intensities are consistent between instruments equipped with the rotary vane pump and the Agilent IDP-3 Dry Scroll Pump.

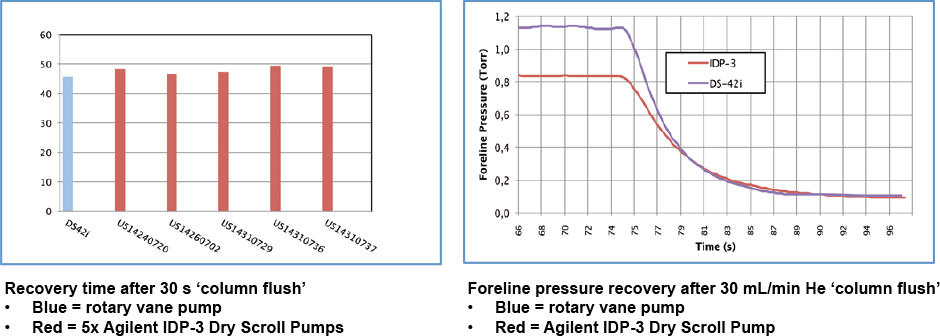

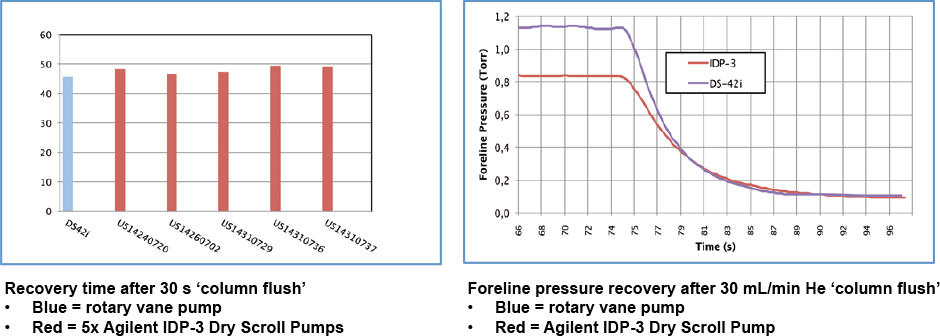

Figure 2. Time for the analyzer and foreline pressures to return to base level (flow = zero) was consistent between the rotary vane pump and the Agilent IDP-3 Dry Scroll Pump.

Comparable analytical performance

To compare the performance of the Agilent IDP-3 Dry Scroll Pump against the oil-sealed rotary vane pump, we considered analytical performance, vacuum performance, and audible noise. To confirm the analytical performance, we ran complete manufacturing tests for the GC/MS—the same tests we apply for those equipped with oil-sealed pumps. Figure 1 shows background spectra for the two pump options. In every analytical performance test, the Agilent IDP-3 Dry Scroll Pump delivered equal or better results than its oil-sealed counterpart.

Vacuum performance: consistent recovery time

The ability of the GC/MS forepump to evacuate gas after a sample injection is directly related to the instrument sample throughput. As a worst-case scenario, we examined the ability of the Agilent IDP-3 Dry Scroll Pump to return the instrument to baseline pressures after a 30 mL/min He column flush (Figure 2).

Reduced noise for a better work environment

Audible noise produced by the forepump in the GC/MS is typically the largest contributor to the overall noise of the instrument. When we compared the average noise of five Agilent IDP-3 Dry Scroll Pumps against a selection of oil-sealed rotary vane pumps, the IDP-3 was consistently 2 dBA lower in noise at three of four relative positions, with inconclusive measurements at the fourth. The logarithmic nature of the decibel scale suggests that a 2 dB reduction in noise is readily appreciated by the instrument operator.

Go oil-fee

The oil-free Agilent IDP-3 Dry Scroll Pump provides a turn-key, affordable upgrade to oil-free technology for turbo pumped Agilent GC/MS systems. Discover more about this simple, modestly priced upgrade, so you can access environment-friendly dry-pump technology with low ownership cost—and eliminate messy oil changes and the need for used oil disposal.

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – April 2016

All articles in this issue

Analyze low-ppm levels of active sulfur compounds with inert sample path on the Agilent 490 Micro GC

Analyze low-ppm levels of active sulfur compounds with inert sample path on the Agilent 490 Micro GC Fast arsenic speciation for food and urine analysis with Agilent LC-ICP-QQQ

Fast arsenic speciation for food and urine analysis with Agilent LC-ICP-QQQ Simplify achiral-chiral analysis of warfarin metabolites using Agilent 2D-LC/MS solutions

Simplify achiral-chiral analysis of warfarin metabolites using Agilent 2D-LC/MS solutions Optimized detection of gaseous sulfur compounds using Agilent J&W DB-Sulfur SCD GC column and Inert Flow Path

Optimized detection of gaseous sulfur compounds using Agilent J&W DB-Sulfur SCD GC column and Inert Flow Path Oil-free laboratory vacuum eliminates oil mess and disposal costs

Oil-free laboratory vacuum eliminates oil mess and disposal costs Eliminate conventional SEC roadblocks with Agilent AdvanceBio SEC columns

Eliminate conventional SEC roadblocks with Agilent AdvanceBio SEC columns Fast, economical assessment of herbals with Agilent 1290 Infinity LC system and LC columns

Fast, economical assessment of herbals with Agilent 1290 Infinity LC system and LC columns Agilent 5977B GC/MSD with HES offers improved VOC detection limits

Agilent 5977B GC/MSD with HES offers improved VOC detection limits

Figure 1

Mass assignments and relative intensities are consistent between instruments equipped with the rotary vane pump and the Agilent IDP-3 Dry Scroll Pump.

Figure 2

Time for the analyzer and foreline pressures to return to base level (flow = zero) was consistent between the rotary vane pump and the Agilent IDP-3 Dry Scroll Pump.