Vials, Caps, and Septa

All you need to know about vials, their various types, and common uses in chromatography laboratories.

What is a vial?

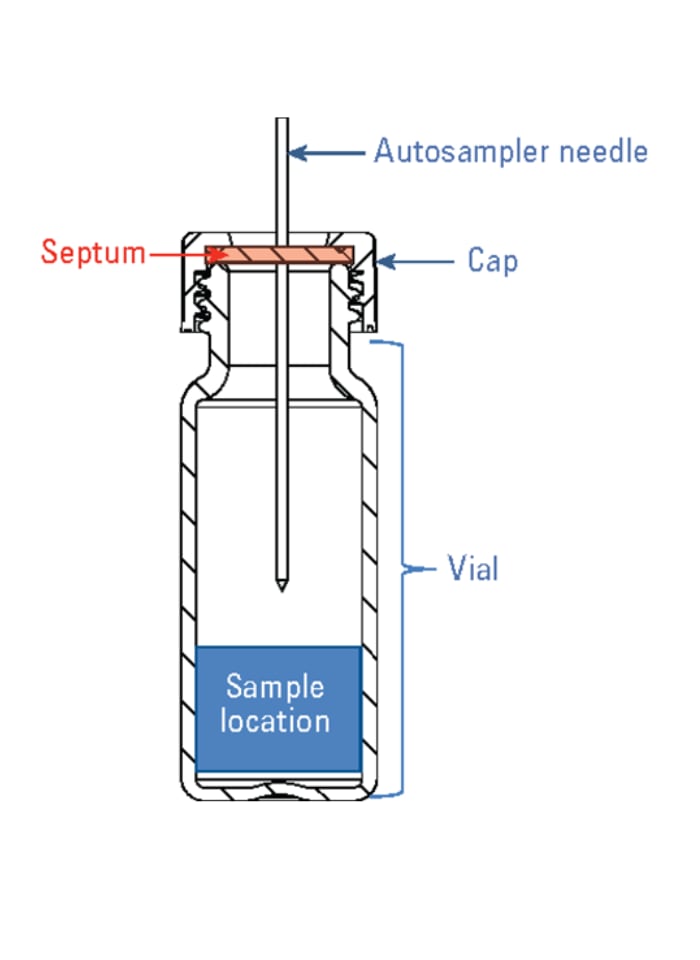

A sample container in analytical analysis and testing contains 3 important components - vial, cap and septum, when combined provides your sample a fully contained environment prior to being introduced into the analytical workflow via the injection needle.

The vial, particularly the chromatography vial, is the base component that collects the sample matrix in analytical workflow. Chromatography vials commonly come in 3 top styles, including screw, crimp and snap. Vials designed specifically to be used with autosamplers for sample introduction are called autosampler vials. Vials are a critical part of your analytical workflow. Substandard vials, caps, and septa can lead to sample loss, contamination, and damaged autosampler needles.

Read on to learn more about the key features, types of vials, tips for vials selection and maintenance.

Cap and septum

Several essential consumables work in tandem with the autosampler vial during sample containment. These consumables, including the closure (also known as cap), cap septum (also known as liner), and insert, play a crucial role in providing a safe and secure location for your sample prior into introduction into the analytical workflow, whether that be either an HPLC or GC system.

The cap (also known as the closure)

The closure is used to create a seal between the vial and the septum. Like the autosampler vial, they come in 3 top styles, snap, crimp, and screw corresponding to autosampler vial they will be used. The top style usually defines what type of material is available. Screw top and snap top closures come in polypropylene, polyethylene, or polyurethane, as these materials allow for thread designs. Non-moldable materials such as aluminum are commonly used to produce crimp top closures.

The septa (also known as the cap liner)

Septa are small discs used to create a resealable barrier at the top of the vial, preventing leaks and maintaining consistent pressure within the sample vial with the closure. The septum allows a needle (from a manual or automatic syringe) to enter the vial and extract the sample for the next stage of separation. It must exhibit resilience to repeated needle piercings and be chemically inert to avoid contaminating the sample matrix.

Septa can be made from a range of materials including PTFE, silicone, red rubber, fluoroelastomers, and butyl to name a few. The materials are layered together in one of three options:

- Single layer: Usually made from red rubber or PTFE for one use only

- Bi-layer: Made from two distinct materials – one to create a barrier (usually PTFE) and one to allow for resealing (usually silicone)

- Tri-layer (also known as a sandwich septum): Still made from two distinct materials – usually silicone surrounded on both sides by PTFE

Stackable tolerance of vial, cap and septum

It’s important to make sure all 3 components have been designed with each other in consideration. Small differences in the design of one product can negatively impact compatibility with the others leading to sample loss, workflow issues, and subsequent productivity loss. It’s recommended to source all 3 components from the same supplier who controls the design of each component.

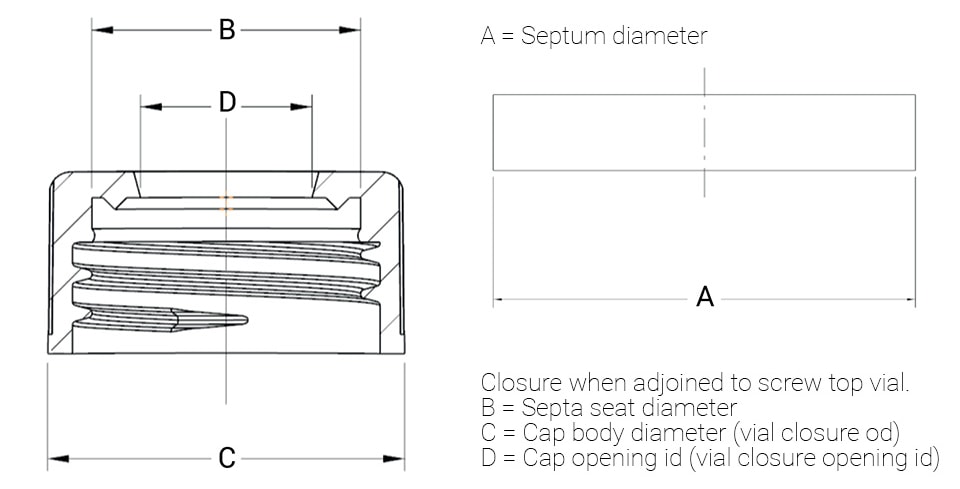

Dimension requirements of vial, cap and septum

The mechanical design of the autosampler vial includes parameters such as vial outer diameter, vial length, interior depth, wall weight, crimp outer diameter, crimp width and neck inner diameter. These critical dimensions collectively influence the relationship with the septum, closure, autosampler tray and autosampler needle. Missing any one of these dimensions can lead to sample loss, damage to the autosampler and reduction in overall productivity.

See the following diagram and table which provide you with the relationship between various dimensions for the vial and the corresponding closure:

|

Cap Type |

Septum/Septum Seat (d) |

Vial Closure (od) |

Vial Closure (Opening id) |

Comments |

|

2 mL Screw – wide opening |

9 mm |

12 mm |

6 mm |

|

|

2 mL Crimp – wide opening |

11 mm |

11 mm |

6 mm |

Closure od and septum seat diameter are very close since the crimp cap wall is thin |

|

2 mL Snap – wide opening |

11 mm |

12 mm |

6 mm |

|

|

2 mL Screw – short opening |

8 mm |

12 mm |

5 mm |

Closure od is measured at the flared base |

|

20 mm Headspace screw |

18 mm |

19 mm |

8 mm |

Closure od is measured at the flared base |

|

20 mm Headspace crimp |

20 mm |

21 mm |

9 mm |

The septum has a larger od than the septum seat diameter to provide a snug fit and prevent septum loosening |