Access Agilent eNewsletter February 2016

Reduce carryover and enhance analysis speed with new Agilent 1290 Infinity II Vialsampler

Martin Greiner, Agilent Senior Product Manager, Analytical HPLC & CE

Analytical labs are pressured to shorten time to results by providing faster analyses while maintaining quality. They cannot tolerate carryover that could give erroneously high concentrations of a compound or could suggest impurities that do not actually exist in the sample. Because many labs work with vials and do not require well plates or other sample containers, Agilent has developed a pure vial-based LC autosampler for our high-end 1290 Infinity II LC system.

This new sample injection device, the Agilent 1290 Infinity II Vialsampler, meets the following design goals:

- Provides robust and reliable injections from vials for any type of routine work

- Supports classic HPLC up to time-optimized high-end UHPLC modes

- Offers an economically balanced system for labs that upgrade to UHPLC performance

To ensure robust performance over tens of thousands of injections, we leveraged well-proven mechanical vial gripper technology from existing LC samplers used for many years on Agilent HPLC systems. With further improvements and new electronics, the Agilent 1290 Infinity II Vialsampler is even more robust and definitely much faster than previous systems. The injection cycle times are only 18 seconds for small-volume injections.

Shorten time to results

Fast injection cycles combined with very short run times are essential to reduce time to results. As the newest member of the Agilent Infinity II systems portfolio, the 1290 Infinity II Vialsampler can hold pressures up to 1300 bar, which provides easy access to high-speed methods that use sub-2 µm columns. Many publications have shown the shorter run times with maintained resolutions for UHPLC methods that run at elevated pressures.

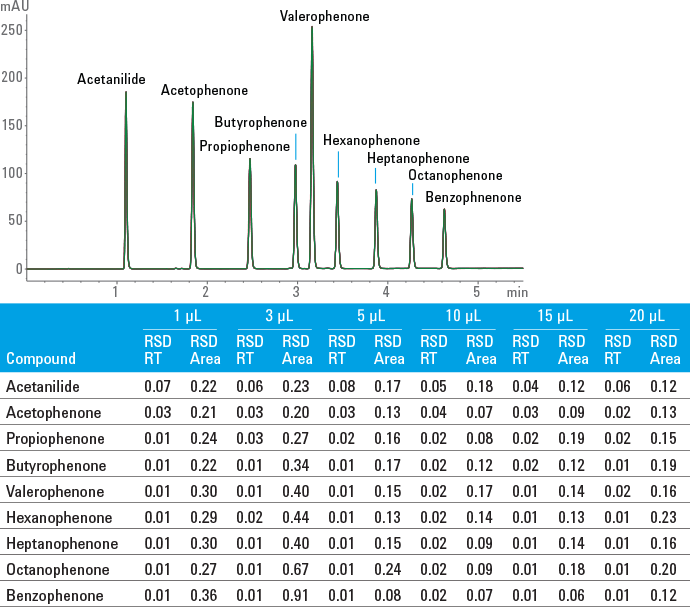

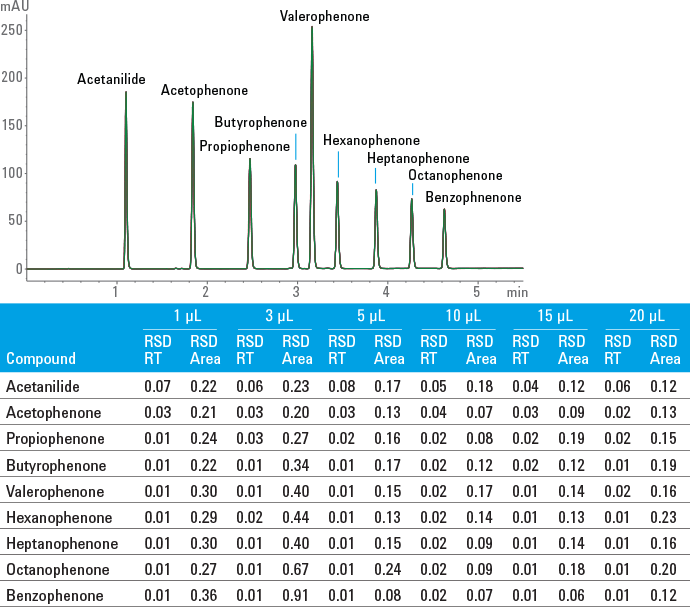

Figure 1. Overlay of 10 consecutive analyses for a 5-µL injection volume, and table of relative standard deviation (RSD) values for retention time (RT) and area.

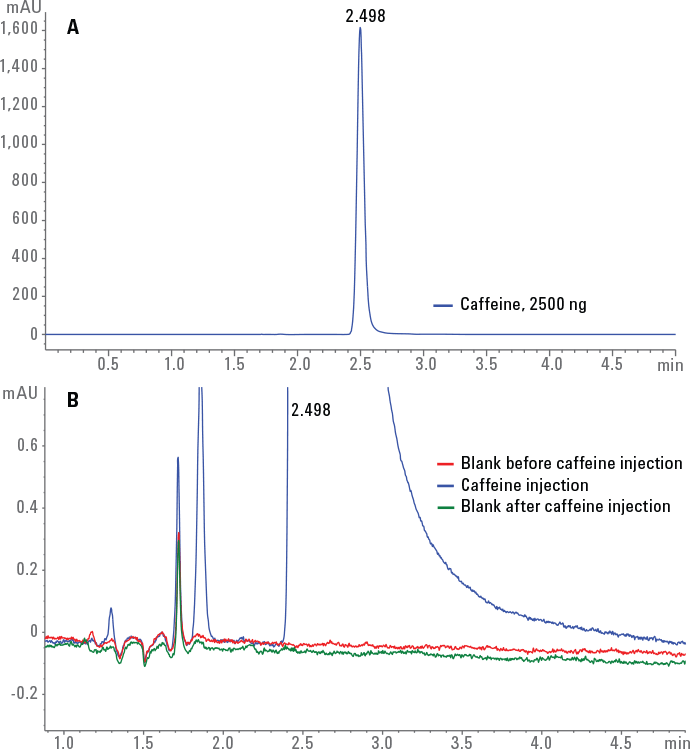

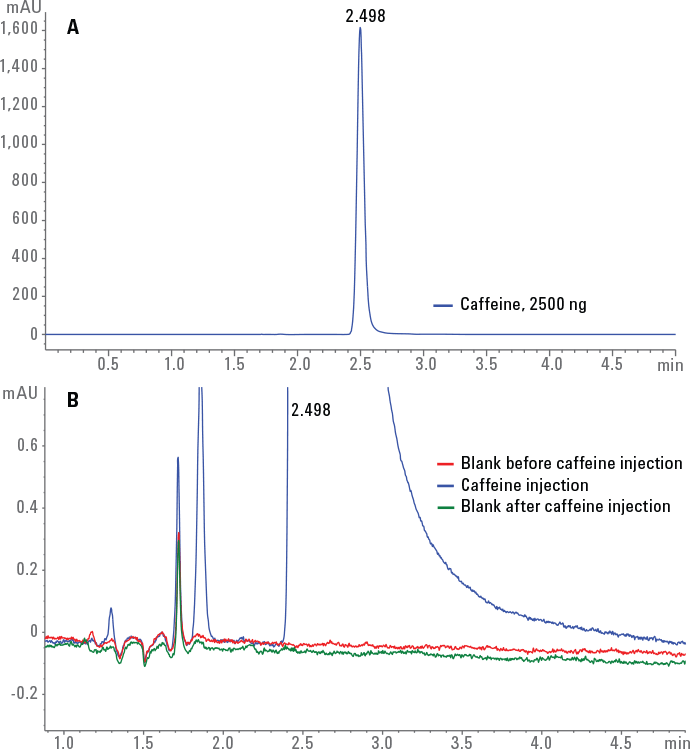

Figure 2. UV chromatogram after high-level (2500 ng) caffeine injection shows no detectable carryover.

Another way to speed time to results is to avoid lost time when the system is idle due to maintenance or hardware changes required by evolving application needs. To reduce the time spent on hardware reconfiguration, this autosampler provides a very wide range of injection volumes. The new sampler by default delivers 0.1-µL up to 20-µL injections with exceptional precision, as shown in Figure 1. You can adjust the injection volume from 0.1 to 1500 µL, which provides free choice of the volume from one method to the next. This flexibility allows you to accomplish most analytical tasks without user interaction with the hardware.

Minimize carryover

A well-known problem with sample injections is that either concentrated samples or sticky matrix compounds that are not soluble enough to be washed away lead to carryover for subsequent runs. Those false positive results can have significant impact on quality of the analysis. To minimize carryover, the Agilent 1290 Infinity II Vialsampler is equipped with a flush port, where the injection needle can be placed and washed intensively on the outer side. The inner side of the injection needle is washed constantly by the LC solvent, so the eluting gradient removes left-over materials. The combination of the flow-through principle with a programmable outer needle wash leads to efficient cleaning and extremely low carryover values.

Typical carryover tests with chlorohexidine and caffeine (Figure 2) show no visible carryover with UV-detection. You need highly sensitive MS detection to define the carryover values (specified at less than 40 ppm) for such compounds.

Economic entry into the Agilent 1290 Infinity II systems

To ensure that the Agilent 1290 Infinity II Vialsampler meets the various needs and budgets of laboratories, we designed a highly integrated device. The basic autosampler can hold an optional sample cooler inside the module. The cooler controls sample temperature down to 4 °C when you need cooling to improve sample stability or to optimize reproducibility for analyses in large sequences.

Another addition directly into the sampler module is the optional integrated column compartment (ICC) to control temperature for up to two columns. It has a maximum temperature of 80 °C and enables reproducible chromatography at optimized resolution.

The integration concept of the Agilent 1290 Infinity II Vialsampler offers two main advantages:

- A complete HPLC system is reduced to three compact modules that contain pump, degasser, Vialsampler, sample cooler, column oven, and detector.

- The system costs less than a classic multi-module setup.

When you need an affordable vial-based LC autosampler that shortens injection cycles, reduces carryover, and performs reliably in a pressure range up to 1300 bar, explore details about the Agilent 1290 Infinity II Vialsampler. See the references below for additional information.

References

- “Performance Characteristics of the Agilent 1290 Infinity II Vialsampler,” 5991-6147EN.

- “Analysis of Food Preservatives Using the Agilent 1290 Infinity II LC,” 5991-5620EN.

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – February 2016

All articles in this issue

New Agilent AdvanceBio SEC column simplifies mAb/ADC analysis

New Agilent AdvanceBio SEC column simplifies mAb/ADC analysis Support sustainability and maximize value for your labs by selling or buying used instrumentation

Support sustainability and maximize value for your labs by selling or buying used instrumentation Ask the Expert: Where can I go for expert advice on dissolution issues and techniques?

Ask the Expert: Where can I go for expert advice on dissolution issues and techniques? Agilent GC/MS/MS enables trace level analysis of dioxins in environmental samples

Agilent GC/MS/MS enables trace level analysis of dioxins in environmental samples Agilent Inert Flow Path for GC and GC/MS minimizes surface activity that compromises your results

Agilent Inert Flow Path for GC and GC/MS minimizes surface activity that compromises your results Tip: One call to Agilent ensures optimal performance of your PerkinElmer systems

Tip: One call to Agilent ensures optimal performance of your PerkinElmer systems Agilent AdvanceBio Peptide Mapping columns to solve glycan mapping challenges

Agilent AdvanceBio Peptide Mapping columns to solve glycan mapping challenges Agilent supports GC/MS with fast, accurate FTIR screening of phthalates in toys

Agilent supports GC/MS with fast, accurate FTIR screening of phthalates in toys Reduce carryover and enhance analysis speed with new Agilent 1290 Infinity II Vialsampler

Reduce carryover and enhance analysis speed with new Agilent 1290 Infinity II Vialsampler

Figure 1

Overlay of 10 consecutive analyses for a 5-µL injection volume, and table of relative standard deviation (RSD) values for retention time (RT) and area.

Figure 2

UV chromatogram after high-level (2500 ng) caffeine injection shows no detectable carryover.