Access Agilent eNewsletter, May 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

UHMI technology enables the analyses of samples with very high salt matrix by Agilent 7900 ICP-MS

By Wim Proper

Eurofins Analytico, Netherlands

and Ed McCurdy

Agilent ICP-MS Product Marketing

The development of new inductively coupled plasma mass spectrometry (ICP-MS) instrumentation and technologies at Agilent is strongly influenced by user requirements. Agilent considers user input during the specification of new instruments, and works with partner labs to “road-test” upcoming hardware and software developments in a real-world production environment.

One Agilent ICP-MS partner lab is Eurofins Analytico in Barneveld, Netherlands, where the range of difficult sample types that are routinely analyzed ensures that new ICP-MS systems can be thoroughly tested prior to general release. The pre-release testing of the new Agilent 7900 ICP-MS at Eurofins focused on the enhanced high matrix capability provided by the Agilent Ultra High Matrix Introduction (UHMI) system, and included the analysis of very high-salt solutions, up to 25% NaCl.

High-salt matrices historically reduced accuracy of analyses

The matrix tolerance of ICP-MS instruments has traditionally been limited by two factors:

- Reduced analyte signal due to ionization suppression

- Long-term drift due to clogging of the interface cones

Signal suppression occurs when a high matrix load absorbs so much of the plasma’s energy that there is insufficient residual energy to ionize the analyte atoms. Signal suppression is a particular problem for poorly ionized analytes (As, Se, Cd, Hg, etc.) in samples that contain high levels of easily ionized elements (Na, K, etc.). The latter contribute a large population of free electrons that suppress the ionization of poorly ionized analytes.

Similarly, clogging of the interface cone orifices occurs when the plasma has insufficient energy to completely decompose the sample matrix, and the residual matrix condenses (deposits) on the cones. The matrix tolerance of an ICP-MS is improved by operating the plasma under robust conditions (low CeO/Ce ratio); Agilent ICP-MS systems are routinely operated at a CeO/Ce ratio of 1% or below. Agilent’s HMI technology for the 7500 and 7700 Series ICP-MS and 8800 ICP-QQQ extends matrix tolerance to 2.5% total dissolved solids (TDS) by diluting the sample aerosol as it passes from the spray chamber to the torch, so reducing the matrix and aerosol load.

Enlarge

Enlarge

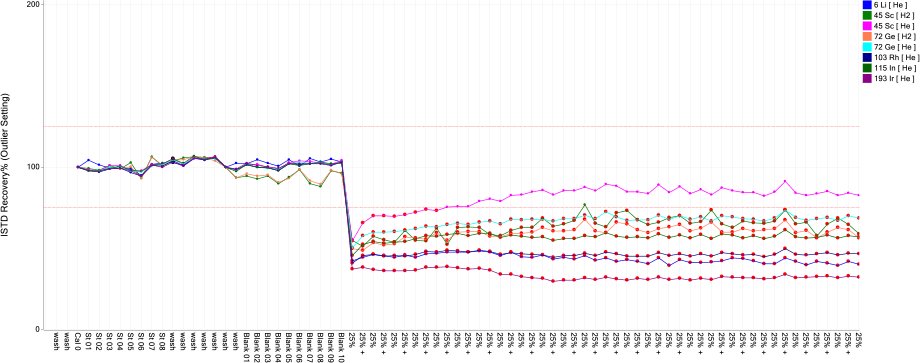

Figure 1. Internal standard signal in 50 samples of 25% NaCl matrix.

Enlarge

Enlarge

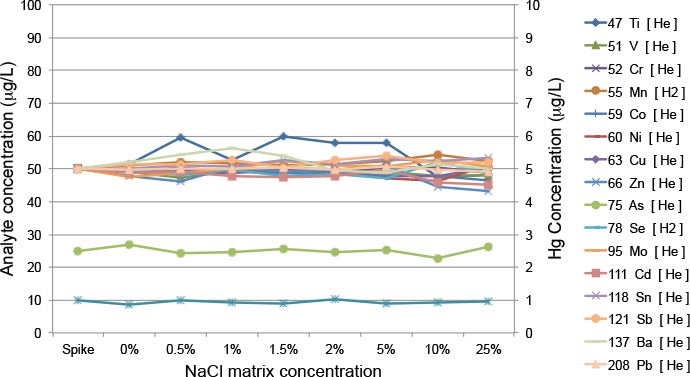

Figure 2. Spike recovery in variable NaCl matrices.

UHMI technology provides unprecedented matrix tolerance

The Agilent 7900’s optional UHMI system (described in a previous article) extends the matrix tolerance of the instrument by a further factor of ten, which allows samples up to 25% TDS to be measured. UHMI is a dilution technology, but it avoids the downsides of conventional liquid dilution (time, cost of reagents, potential for errors and contamination, and waste disposal costs) by diluting the sample aerosol using clean argon gas. This technique improves plasma robustness, and the dilution factor can easily be calibrated and reproduced reliably by automatic adjustment of the nebulizer and dilution gas flows.

Figure 1 shows the internal standard signals for an aqueous calibration followed by fifty 25% NaCl solutions, run at UHMI-100. While the signal level in the NaCl matrix is reduced by about 50% compared with the aqueous standards (mainly due to sample transport, nebulization, and spray chamber effects), the ISTD signals are all reduced by about the same amount (no mass bias) and remain stable throughout the four hours of 25% NaCl analysis. This good stability of the uncorrected ISTD signals confirms that no interface clogging occurred.

The ability to measure 25% salt solutions is unprecedented for ICP-MS, but the most remarkable aspect of the performance of the new Agilent 7900 ICP-MS with UHMI is in the consistency of results in widely variable sample matrices. Figure 2 shows the measurement of a 50 ppb trace element spike (25 ppb for As, 1 ppb for Hg) in a NaCl matrix, calibrated against non-matrix matched standards. The same spike was added to samples that contained a range of matrix levels from 0 to 25% NaCl. The quantitative results for the spiked elements are accurate (the actual spike concentration is shown as the first point) and consistent for all matrix levels, an astonishing achievement. Even the Hg spike at 1 ppb was measured accurately (average recovery of 93%) and consistently (RSD of 6.3% among the eight different NaCl matrix levels).

Learn more about the exceptional matrix tolerance of the Agilent 7900 ICP-MS

For a closer look at the benefits of the Agilent 7900 ICP-MS for the analysis of high matrix samples, download Agilent Application Note 5991-4257EN today.

Agilent ICP-MS Journal

Are you interested in trace metals analysis and eager to keep up-to-date with the latest developments in the field of ICP-MS? Then we invite you to take a closer look at Agilent’s dedicated ICP-MS Journal. Published four times a year and available as a PDF, you can view the latest issue of the ICP-MS Journal, plus all previous copies, by visiting the ICP-MS Journal Archive.

To receive a personal copy of the ICP-MS Journal direct to your inbox, please sign up here.

>> Update My Profile | Subscribe to Access Agilent | Article Directory