Access Agilent eNewsletter, January 2015

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Fast and portable FTIR for polymer analysis

By John Seelenbinder

Agilent Marketing Manager, Mobile Measurement FTIR Products

Polymeric materials or products made from polymers must be correctly labeled, meet specification, and perform as intended. However, the ability to determine polymer suitability is complicated by the large variety of formulations, as well as ever-increasing numbers of global manufacturers and distributors.

FTIR (Fourier transform infrared spectroscopy) is a sensitive and specific molecular analysis method, well-suited to the positive identification of polymers, plastics, elastomers, composites, and coatings. With FTIR, you can verify the identity of a material, detect counterfeits, ensure that overall quality and formulation specifications are met, and measure the presence of additives. In this article, we look at three demonstrations of the value of FTIR for polymer analysis, taken from a wide range of Agilent Application Notes.

Enlarge

Enlarge

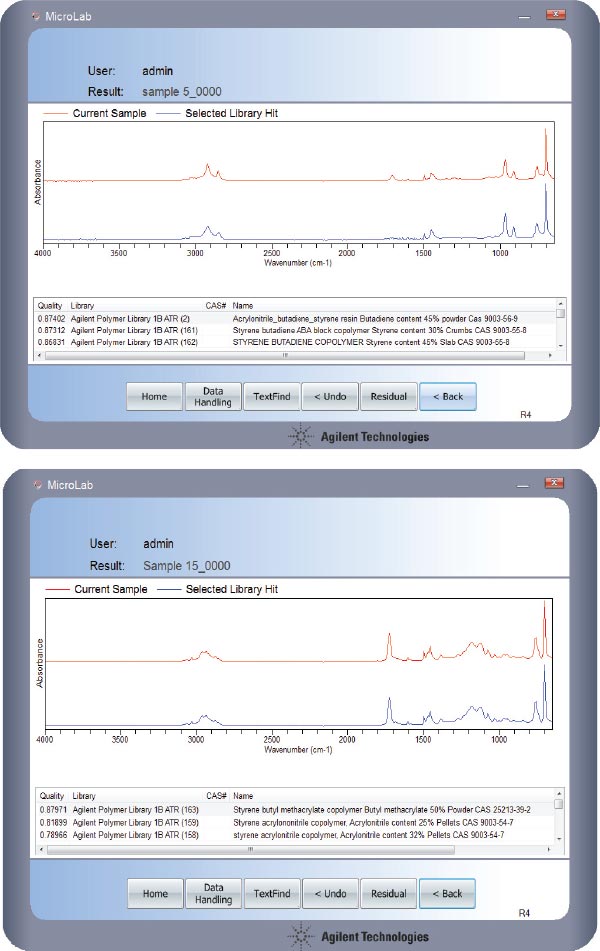

Figure 1. Agilent MicroLab software shows the spectrum and identity of the unknown sample, together with the spectrum of its best library match.

Rapidly and positively identify materials

Various classes of polymeric materials have similar structure, but small deliberate changes in the formulation cause these compounds to have different use and wear properties. FTIR is particularly useful for positive identification of these advanced materials. The recent availability of Agilent handheld and portable FTIR analyzers has added a new dimension to the analysis of polymers, plastics, elastomers, and composites.

Figure 1 shows how you can use the Agilent 4300 Handheld FTIR to identify waste polymer material from electronics equipment. After measuring the unknown sample, Agilent MicroLab Mobile FTIR software automatically searches the on-board spectral database for the best match. It displays the spectrum and identity of the unknown sample, along with the spectrum of its best library match and a numerical value that reflects the quality of the match. Full details of this application are freely available in Agilent publication 5991-4122EN.

Assess phthalate concentration – with minimal sample preparation

Many common plastic consumer products contain high levels of toxic chemical additives known as phthalates. Phthalates are plasticizers that make plastics more flexible, durable, and softer. Typically, 15 to 30% phthalates are added to a base polymer such as polyvinyl chloride (PVC), vinyl and other widely used polymers. Because no chemical bonds exist between the plasticizer and the polymer, the plasticizers can easily leach out to contaminate the surrounding environment or be ingested by humans.

In the United States, the Consumer Product Safety Commission (CPSC) has developed a standard operating procedure for the measurement of phthalates. It specifies FTIR as an optional prescreen to determine gross phthalate contamination. The CPSC concentration limit – 0.1% each for the six banned phthalates – is based on the individual plasticized parts of a children’s toy or child-care product.

Enlarge

Enlarge

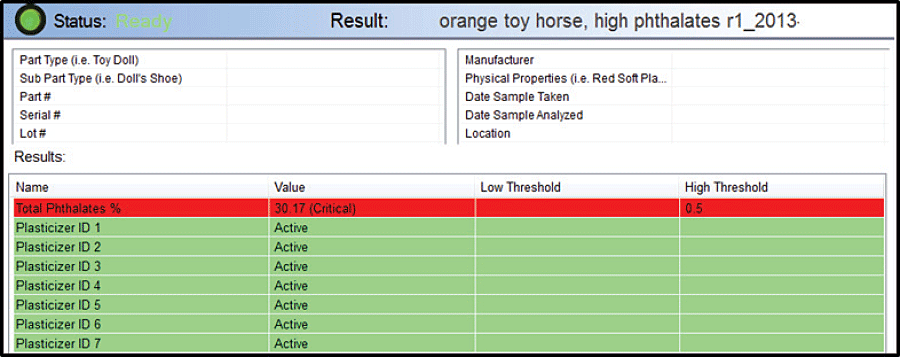

Figure 2. The Agilent 4500a FTIR reveals very high phthalate levels in a toy horse made from plasticized PVC.

You can use Agilent FTIR analyzers and associated calibrated methods to accurately measure levels of phthalates in plastics down to 0.1%. This combination of technology and methodology allows you to rapidly screen large numbers of parts and objects for phthalate content with little or no sample preparation. The self-contained and portable Agilent 4500a FTIR is the primary choice for phthalate screening and plastic identification. Figure 2 shows a typical result from an analysis of a child’s toy. Read more in Agilent publication 5991-3649EN.

The Agilent 4500 Polymer ID Package is a complete analyzer that enables both positive material identification and analysis of phthalate concentrations. This package includes the 4500 instrument, a polymer library, and the calibrated method for measurement of phthalates in PVC plastics. It provides a turnkey, mobile solution for polymer analysis.

Enlarge

Enlarge

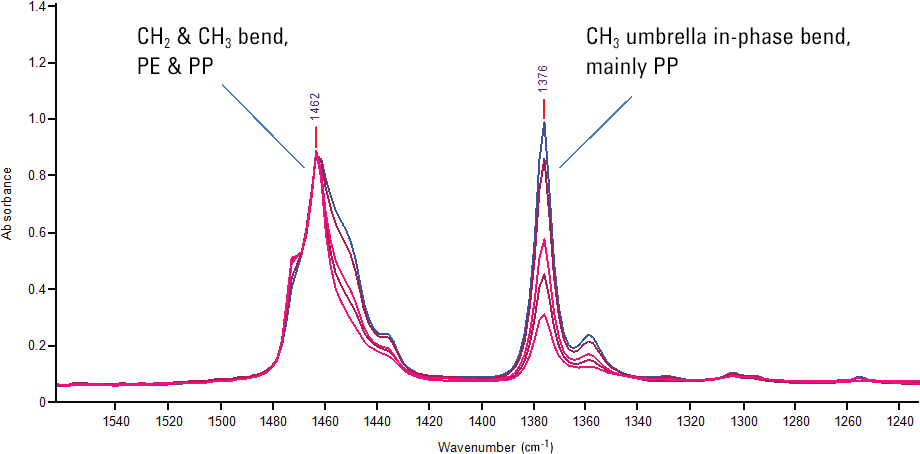

Figure 3. The overlaid aliphatic bend region of the FTIR PE-PP blend calibration spectra provides the percent PE in a PE-PP blend.

Measure polymer composition in remote locations

Polyethylene (PE) is the most common group of thermoplastic polymers due to its low cost and versatile physical properties. PE is blended with polypropylene (PP) to improve its physical properties, such as low-temperature impact performance. The composition of these blends influences performance, and the correct mixing of the pure polymers (PE and PP) can eliminate the need for costly synthesis of new block copolymers. Knowledge of the composition of these blends is also critical when you recycle polyolefins in waste and scrap.

In an example taken from Agilent publication 5990-9785EN, we used the Agilent Cary 630 FTIR to examine a PE-PP blend (Figure 3). The quantitative method for percent PE uses a ratio of the methyl 1376 cm-1 (mainly PP) band to the 1462 cm-1 (methyl and methylene bend) band. Although originally designed as a laboratory application, this analysis has been extended for use in factory and remote locations with the Agilent 4500 Series Portable FTIR.

Analyze advanced materials with multiple methods

Agilent FTIR and other molecular spectroscopy systems provide insights into bulk and detailed structure of polymers in the field and in the lab. Agilent FTIR supplies and standards accelerate identification. In addition, our suite of molecular spectroscopy solutions can tackle any polymer analytical challenge, from routine measurements and troubleshooting to innovative applications.

>> Update My Profile | Subscribe to Access Agilent | Article Directory