To resolve potential spectral interferences on multiple elements in semiconductor samples, the 8900 can often be operated in a single multi-tune method that switches between gas modes. These modes typically include no gas, collision (helium), and reactive (using one or more reaction gases).

Depending on the sample matrix and analytical objectives, many 8900 ICP-QQQ methods rely on mixed gases. For example, if a method requires the use of ammonia (NH3) cell gas for interference control or oxygen (O2) for organic solvent analysis, the gases are supplied via 10% NH₃/He or 20% O₂/Ar mixes, respectively. However, the requirement to use mixed gases presents challenges for some facilities, such as:

- Additional investment: Cost of installing mixed gas supply infrastructure in the lab

- Supply chain risk: Difficulty sourcing high-purity specialty mixed gases

- Regulatory hurdles: Lack of Safety Data Sheets (SDS) for certain mixed gases

To address these issues, Agilent now supports pure gases with the 8900 ICP-QQQ, providing semiconductor users with more choice, greater flexibility, and simplified gas management.

Instrument compatibility: Gas options

Semiconductor laboratories can choose the best gas options for their 8900 ICP-QQQ to suit their facilities:

Choice of 8900 ICP-QQQ models for new customers:

- Agilent 8900 ICP-QQQ (G3665AA) #210 supports pure NH₃ as a cell gas, with pure O₂ available as an optional upgrade for organic solvent analysis*

- Agilent 8900 ICP-QQQ (G3665AA) #200 remains available for mixed gas operation

Upgrade options:

- Agilent 8900 #100 and 8900 #200 instruments can be fitted or retrofitted with the following pure gas kits:

- Pure Ammonia Cell Gas Kit (G5726A) for cell gas applications

- *Pure Oxygen Option Gas Kit (G5725A) for organic solvent analysis

Performance comparison of pure vs mixed ammonia

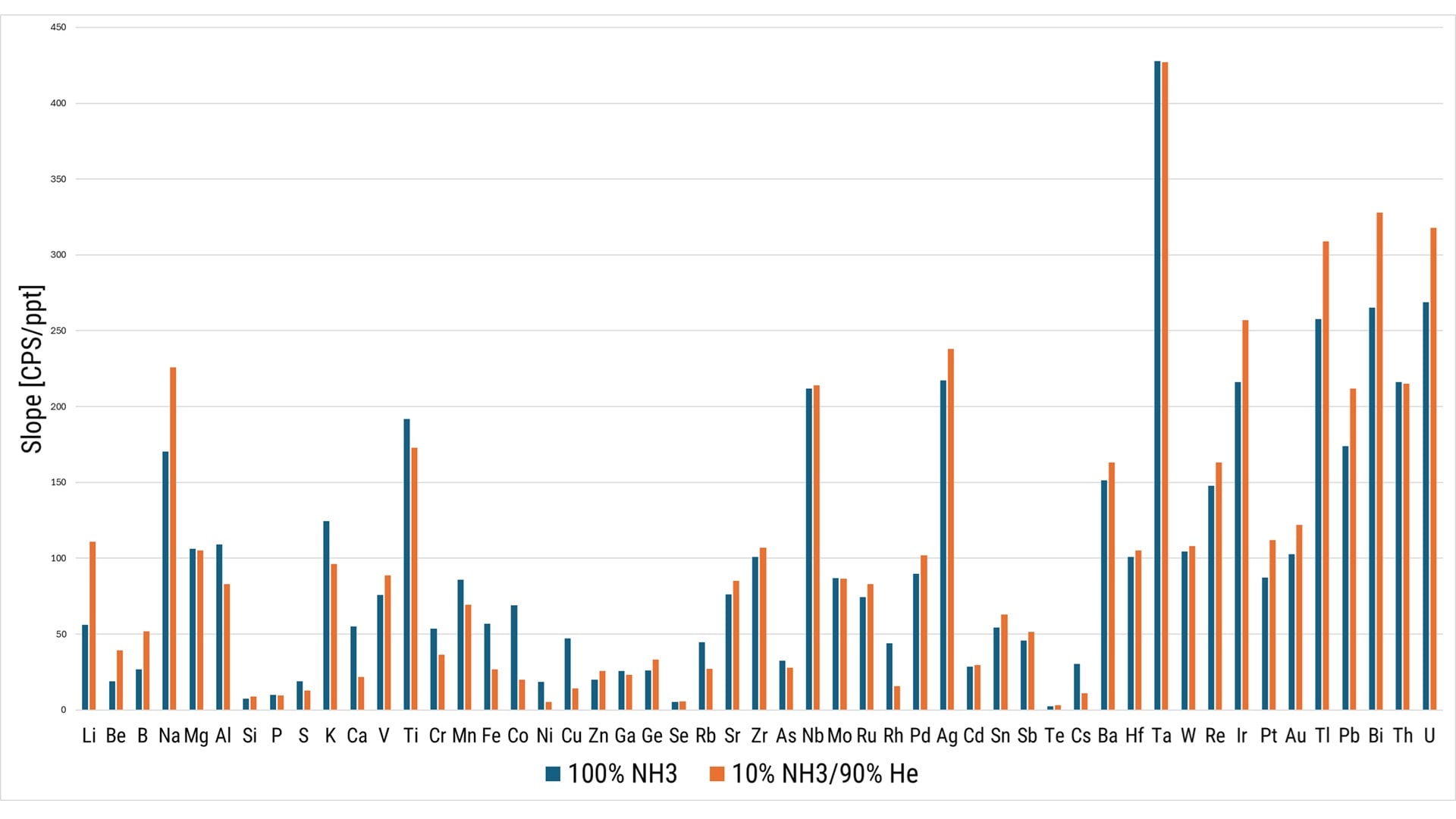

Pure ammonia and 10% NH₃ in He provide equivalent cell‑gas performance, ensuring consistent data quality regardless of the 8900 ICP-QQQ instrument’s configuration (Figure 1).

Minimizing contamination risk in ultratrace analysis

Ultratrace analysis demands strict control of contamination at every stage of the workflow. To minimize risk from contaminants, users have emphasized the need to place large sample bottles directly on the autosampler in flexible positions, enabling analysis directly from the original container. Larger volumes reduce the number of transfer steps, significantly lowering the chance of contamination during measurement. However, accommodating these larger bottles requires more space than traditional autosamplers like the Agilent SPS 4 can provide.

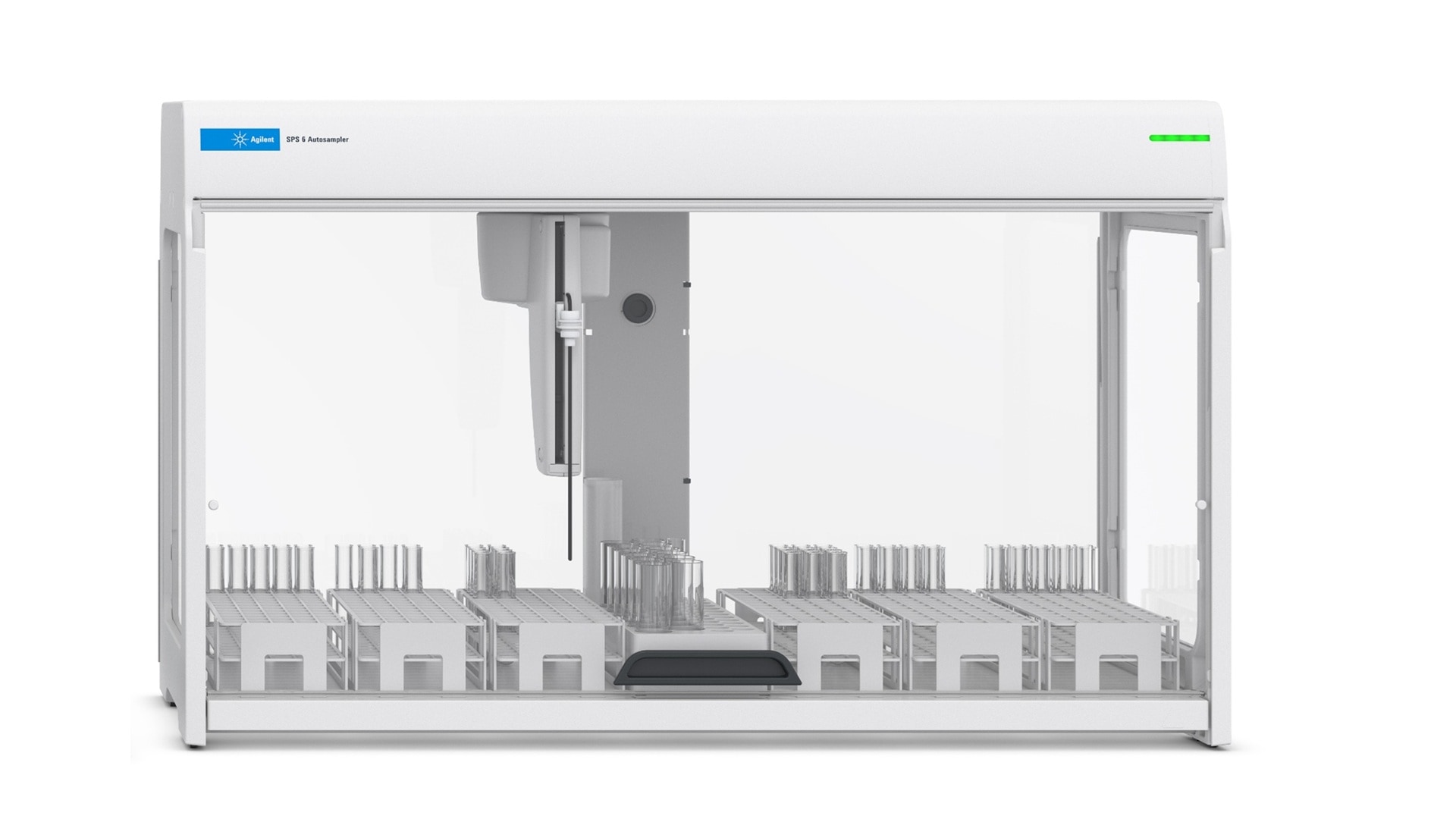

To address this limitation, Agilent has developed the new Agilent SPS 6 autosampler with expanded bottle space, enabling direct placement of much larger bottles. When used with Agilent ICP-MS MassHunter version 5.4 or later, the configurable rack location enables flexible positioning and bottle size selection, helping semiconductor manufacturers reduce contamination risk and improve operational efficiency.

Similarities and differences of the SPS 4 and SPS 6 autosamplers

- Both autosamplers support flexible positioning and accommodate variable bottle sizes when managed by ICP-MS MassHunter version 5.4 or later*.

- Both autosamplers accommodate 500- and 1000-mL bottles, reducing contamination risk and improving workflow efficiency.

- Compared to the SPS 4 (G8415A) autosampler, the new SPS 6 (G8417A) autosampler accommodates two additional racks, providing greater bottle capacity and expanded workspace for high sample volume applications.

*The SPS 6 autosampler requires MassHunter version 5.4.1 or later.

Enhanced usability with ICP-MS MassHunter software

Introduced with ICP-MS MassHunter software version 5.4, the Simple Recipe feature supports both pure- and mixed-gas configurations. This allows non-expert users to quickly and accurately set up measurement conditions for ultratrace element analysis of process chemicals.

Also, with each software update, the usability of the 8900 ICP-QQQ for nanoparticle (NP) analysis has steadily improved. ICP-MS MassHunter version 5.4.1 includes enhancements to the method template for single particle (spICP-MS) analysis, enabling higher sensitivity using lower BEC conditions than the previous method template. This improvement is useful as labs increasingly use their ICP-QQQ for both particle analysis and conventional elemental concentration measurements.

Semiconductor-specific benefits

The 8900 ICP-QQQ delivers equivalent analytical performance with either pure gas (model #210) or mixed gas (model #200) configurations. By following the Simple Recipe workflow, users can achieve detection limits below 1 ppt for most elements with either configuration, fully meeting the stringent contamination control standards of the semiconductor industry.

In addition, the large-volume compatibility of the SPS 4 and SPS 6 autosamplers supports these results by minimizing handling steps and reducing contamination risk.

The Agilent SEMI S2 Compliance Kit (G3685A) compliance option is applicable to both mixed-gas and pure-gas configurations, ensuring safety and regulatory compliance regardless of the setup.

Updates inspired by our users

We work closely with our customers to ensure updates to our ICP-MS and ICP-QQQ platforms and ICP-MS MassHunter software are relevant. The decision to broaden the gas options for the 8900 ICP-QQQ to include pure gases and to add autosampler capacity was based on customer feedback.

Depending on your facility's needs, Agilent offers the 8900 #200 (mixed-gas) and #210 (pure-gas) ICP-QQQ models, upgrade options to add pure gases, including pure oxygen for organics analysis, and the SPS 6 autosampler. With updated software, these innovations address contamination control, operational flexibility, and regulatory compliance, enabling ultra-trace elemental analysis and streamlined workflows for semiconductor manufacturers. Agilent remains committed to driving innovation in semiconductor analysis through solutions that evolve with industry requirements.