Access Agilent eNewsletter October 2016

Determination of chemical species in marine fuel oil by multidimensional GC/MS analysis

George Gonzalez, Agilent Global Segment Marketing Manager, Energy and Chemicals

Marine fuel oil is a relatively complex heavy crude oil fraction and commonly used to operate marine vessels (Figure 1). Sometimes fuels are blended and become susceptible to contamination from chemical species that cause engine fouling, and in some cases, serious engine damage. Due to the countless sources of possible contaminates, it is often difficult to positively identify the chemical species and their source of origin.

Figure 1. Container ship powered by marine fuel oil.

Using industry feedback and experience, several potential chemical species were identified as being effective for screening marine and bunker fuel oil. Bunker fuel oil is the primary constituent of marine fuel oil. Various test methods and techniques were used to screen marine fuel oil, and due to the lack of repeatable test results, it has been difficult to identify a specific source of contamination. To address this industry need for a standardized method, the American Society for Standard and Materials (ASTM) issued work item #36704 for the development of a standard test method. In this article, we look at the process of analytical method development performed on an Agilent gas chromatogram (GC) and mass spectrometer (MS) developed at the Bureau Veritas – Inspectorate Laboratory in Pasadena, Texas.

Participating labs get standardized on prep methods, data, and GC/MS analysis

The analytical method development required the designation of a standard and specific list of compounds, easy sample preparation, reliable quantitative data, and accurate qualitative identification. In order to obtain agreement with a standard method, it was important to assure the inclusion of compounds used by those laboratories performing this test. The analytical instrument used by all of the laboratories was a gas chromatograph equipped with a mass spectrometer.

A survey was conducted of all known laboratories screening marine fuel oil for contaminants. Subsequently, a common table (ASTM D7845-16) containing compounds tested by all of the laboratories surveyed was compiled and is shown in Table 1. This compound table was used to develop the proposed standard screening method for determination of chemical species in marine fuel oil. This test method can also be used to detect other compounds because it is based on mass spectrometry.

| Limit of Quantitation mg/kg | |

|---|---|

| n-butyl alcohol | 10 |

| Cyclohexanol | 10 |

| n-butyl ether | 10 |

| n-butyl acrylate | 10 |

| Styrene | 10 |

| alpha-pinene | 10 |

| Phenol | 20 |

| alpha-methyl styrene | 10 |

| beta-pinene | 10 |

| 4-methyl styrene | 10 |

| trans-B-methyl styrene | 10 |

| 3-methyl styrene | 10 |

| 2-methyl styrene | 10 |

| Dicyclopentadiene | 10 |

| Limonene | 10 |

| Indene | 20 |

| 1-phenyl ethanol | 20 |

| para, alpha-Dimethyl styrene | 20 |

| 2,5 dimethyl styrene | 20 |

| 2,4 dimethyl styrene | 20 |

| 2-phenyl ethanol (phenylethanol) | 20 |

| 2-Ethyl Phenol | 50 |

| 2,4 Dimethyl Phenol | 20 |

| 4-Ethyl Phenol (co elutes with 3-ethylphenol) | 20 |

| 2-Phenoxy-1-propanol | 50 |

| 2-Phenoxy ethanol | 50 |

| 4-isopropylphenol | 50 |

| 1-Phenoxy-2-Propanol | 20 |

| Styrene Glycol | 50 |

Table 1. Overview of ASTM D7845-16 contaminant compounds derived from survey results.

Agilent GC/MS solution and columns provided ultra-high resolution and good detection limits

Using the high purity reagent chemicals identified in the survey, a method development analysis was performed by preparing individual compound standard mixtures. These standard mixtures prepared in bunker fuel oil were then used to define the Agilent 7890B GC conditions, including; the inlet, an Agilent J&W DB-1 GC (1 M x 0.15 µm x 1.2 µm DB-1) for the pre-separation column, a pre-separation technique based on an Agilent purged union configured for backflushing through the inlet vent, and column resolution requirements. The analytical column used was an Agilent J&W HP-1 GC Column (100 M x 0.25 µm x 0.5 µm HP1) because it provides ultra-high resolution and also allowed users to develop other methods on the same analyzer.

The mass spectrometer used in the development phase provided good detection limits, however the newer Agilent 5977B Series GC/MSD system delivers significant detection limit and operating efficiency improvement. The GC oven conditions were optimized iteratively in order to obtain the best compound separation and also to eliminate fuel oil mass spectral interference. The MS operating conditions were defined by collecting mass spectral data and selecting molecular ions specific for each compound and sufficient detection limit response.

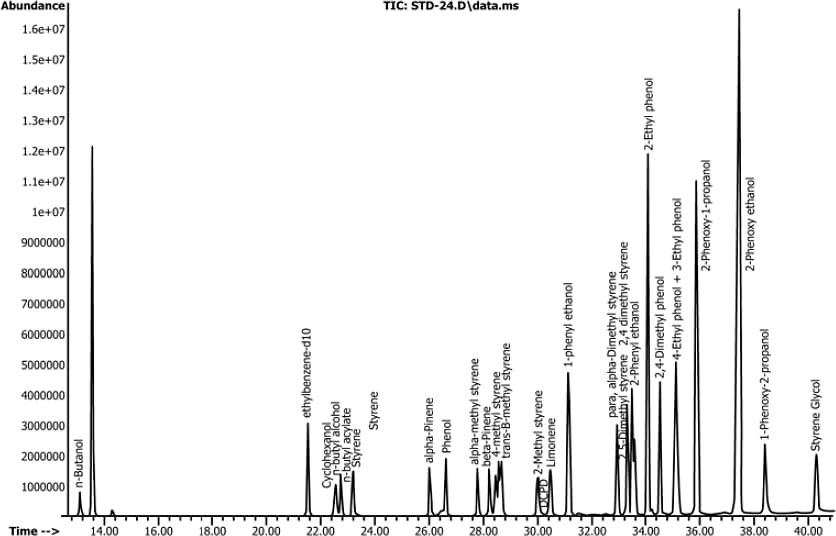

A ruggedness and interim repeatability study were conducted and found acceptable for inclusion in a standard test method. The Agilent based analytical method has been standardized in test method ASTM D7845-16 (Figure 2) and can now be used to screen marine fuel oil for chemical contamination and obtain reliable data. The ASTM standard method process includes regular review and revision to reflect current available technology and product specification changes. Agilent is currently expanding the scope of test method ASTM D7845-16 to include compounds specified by ISO TC 28 SC4 WG 6 on marine fuel specifications.

Agilent offers a vast selection of GC, MS, and GC/MS solutions

Agilent has a wide array of gas chromatography and mass spectrometry, and GC/MS equipment, columns, and software solutions for time-constrained lab managers. These solutions can help your lab improve accuracy, increase efficiency, lower costs, and reduce run times. Discover more about our GC, MS, and GC/MS solutions right now. Then contact an Agilent representative who will be happy to answer any questions you may have about our robust, high-quality products, systems, supplies, and software.

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – October 2016

All articles in this issue

Designed for true mobility—the 490-Mobile takes your lab to the sample

Designed for true mobility—the 490-Mobile takes your lab to the sample Agilent 1260 Infinity II solution delivers fast, sensitive, and automated amino acid analysis

Agilent 1260 Infinity II solution delivers fast, sensitive, and automated amino acid analysis Efficient analytical methods for catecholamines, metanephrines, and related metabolites in urine and plasma

Efficient analytical methods for catecholamines, metanephrines, and related metabolites in urine and plasma Agilent IDP-3 Dry Scroll Pump provides clean, quiet, and reliable GC/MSD analysis

Agilent IDP-3 Dry Scroll Pump provides clean, quiet, and reliable GC/MSD analysis Determination of chemical species in marine fuel oil by multidimensional GC/MS analysis

Determination of chemical species in marine fuel oil by multidimensional GC/MS analysis Tip: Easily transfer Agilent GC/MSD methods to Agilent triple quadrupole GC/MS systems

Tip: Easily transfer Agilent GC/MSD methods to Agilent triple quadrupole GC/MS systems Agilent ICP-QQQ provides unique solutions for nuclear applications

Agilent ICP-QQQ provides unique solutions for nuclear applications

Figure 2

TIC chromatogram using Configuration A.