Access Agilent eNewsletter January 2016

Tip: How to detect leachables from drug container closures in pharmaceutical products

Andreas Tei, Agilent Pharma Segment Manager—Small Molecules

In last month’s article, we examined some of the important parameters surrounding the increasing demand for analysis of extractables and leachables (E&L) in pharmaceutical products. This month, we turn our attention to a specific method involving the detection and identification of extractable compounds from drug container closures.

The four important steps of E&L analysis

An extractable and leachable study for pharmaceutical products contains four major steps. The work starts with a risk assessment of possible interactions of the drug formulation with its drug container and the dosage form. In this example, we looked at all liquid formulations that deliver the drug directly into the blood stream. We used a high-resolution Agilent 6530 Accurate-Mass Q-TOF LC/MS with Agilent MassHunter Mass Profiler as data mining software.

The second step involves a comprehensive extraction protocol using sometimes drastic conditions to create a worst-case scenario and to determine the quantity of all extractable compounds. The next phase covers the toxicological assessment for each extracted compound. We looked at maximum daily intake for all genotoxic compounds or for all compounds with a structure-activity relationship (SAR) that is 0.15 µg/day. All other compounds need to be quantified at concentrations above 5 µg/day. Finally, to determine the analytical requirements for the workflow, an analytical evaluation threshold (AET) for each compound must be calculated, based on the daily intake of the drug product.

For this analysis, compounds need to be reported and their structure has to be tentatively confirmed by database research at concentrations of 1 ppm. A complete compound identification is required above concentrations of 20 ppm. A semi-quantitative determination of the concentration is required from 0.1 ppm to at least 100 ppm, which can be challenging when using external reference compounds for quantitation.

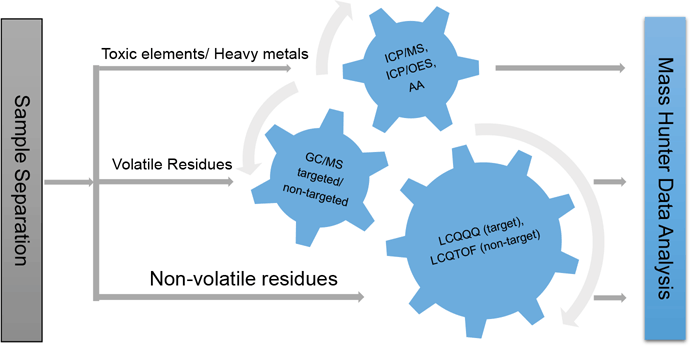

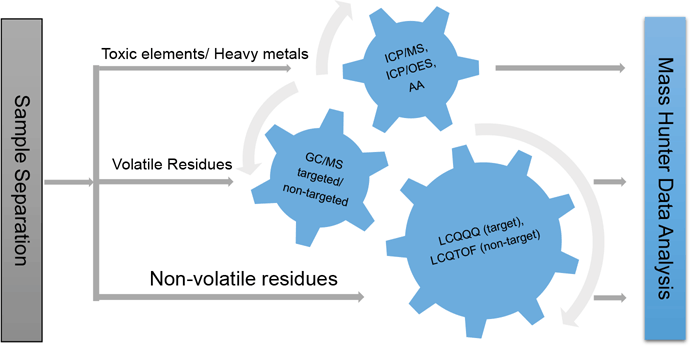

Figure 1. General extractable/leachable workflow to detect a wide class of known and unknown organic/inorganic compounds that may be present in container closure systems at levels linked to risk assessment threshold levels.

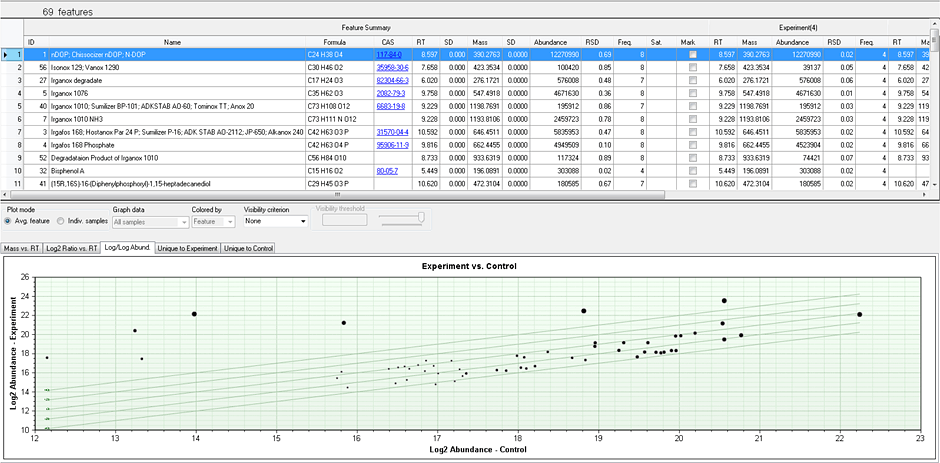

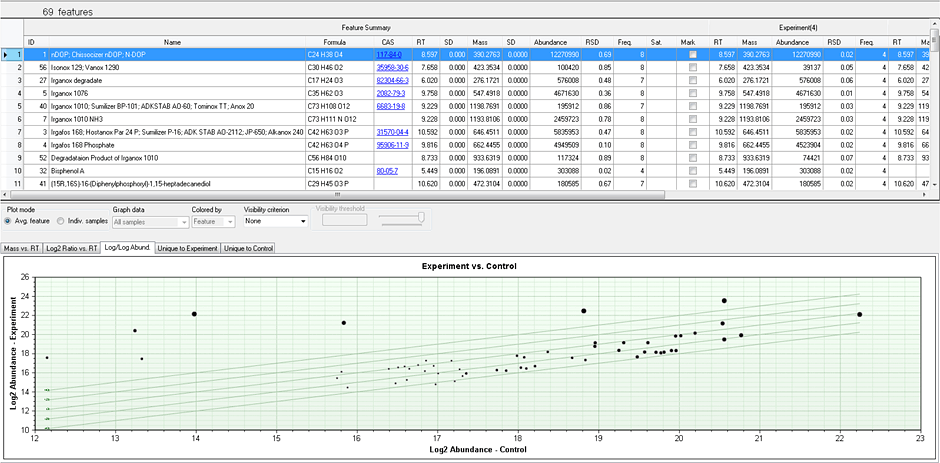

Figure 2. Differential analysis using Agilent Mass Profiler Software (Rev 7.0). PCA plot for routine QA/QC (above), differential plot experiment vs. control (below).

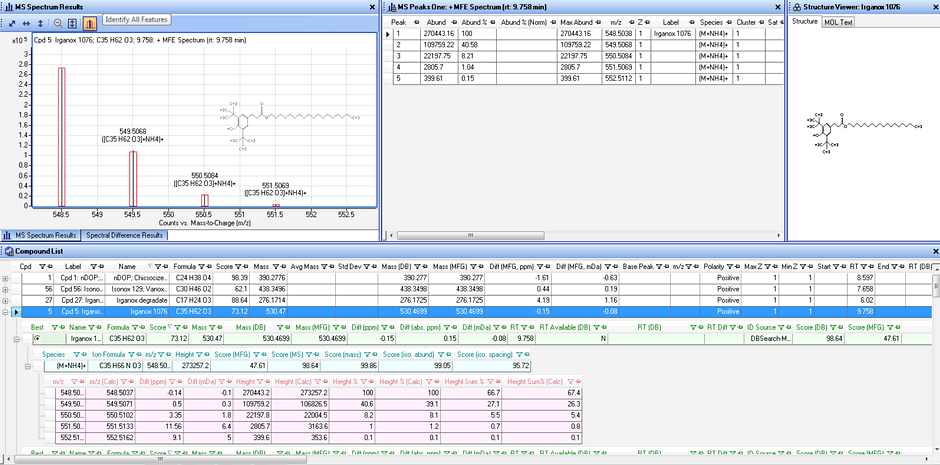

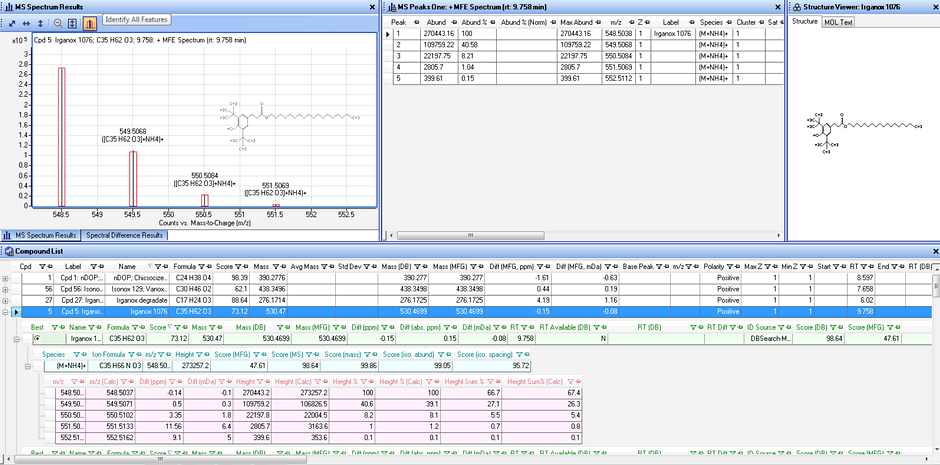

Figure 3. An example of compound identification by high-resolution MS and PCDL research.

Agilent has the right tools for the task

Our objective was to detect a wide class of known and unknown organic/inorganic compounds that may be present in container closure systems at levels linked to risk assessment threshold levels. Agilent offers the most comprehensive instrumentation portfolio, from ICP-MS to high-resolution QTOF LC-MS, combined with intelligent data mining software solutions delivering confident results. Figure 1 shows a general workflow.

A comprehensive compound library

A system suitability test mix containing nine different typical plasticizers—based on references from the literature—was used to develop a generic chromatographic method and to test the LOD/LOQs levels of the instrumentation.

These extracts were analyzed in positive and negative ionization modes using an Agilent Jet Stream electrospray source. The data were combined for the data mining process using Agilent MassHunter Mass Profiler software (Rev 7.0). A differential analysis process from the blank solvent delivered a list of different compounds in the sample extract (Figure 2). They were identified by using a personal compound data library (PCDL) that contains over 1,800 compounds that have been found in plastic materials (Figure 3).

An effective LC/MS workflow for extractables and leachables

In summary, to identify extractables and leachables in drug containers, follow this easy-to-use LC/MS workflow:

- Prepare a system suitability test mix with standard compounds based on the literature

- Develop the LC/MS method based on the test mix

- Extract from an empty drug container

- Acquire data in positive and negative ionization modes

- Use data mining for compound identification

- Identify the compounds by PCDL

Learn more about the latest developments in pharmaceutical analysis

Visit Agilent on the web and explore applications using new ICH and USP methods for elemental analysis by ICP-MS and ICP-OES, GC/MSD analysis of plastic intravenous bag sets, transdermal patches, and generic drug formulations.

What’s more, Agilent offers a series of informative recorded webinars, so take a moment to register today. You can also download our latest published posters that provide easy reference information for display in your labs.

In the coming months, we will continue our series of articles on the analysis of extractables and leachables with a discussion on the use of GC/Q-TOF as the analysis method.

For Research Use only. Not for use in diagnostic procedures. Information is subject to change without notice.

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – January 2016

All articles in this issue

-

What is in your beer? Find out using a Agilent J&W DB-624 Ultra Inert (UI) column with GC/MS static headspace solution

What is in your beer? Find out using a Agilent J&W DB-624 Ultra Inert (UI) column with GC/MS static headspace solution -

Moving biologics to market with automated biopharma workflow solution

Moving biologics to market with automated biopharma workflow solution -

Nobel Prize-winning lab uses Agilent equipment to accelerate natural product discoveries

Nobel Prize-winning lab uses Agilent equipment to accelerate natural product discoveries -

Tip: How to detect leachables from drug container closures in pharmaceutical products

Tip: How to detect leachables from drug container closures in pharmaceutical products -

Fast, accurate absolute-quantification of proteins and antibodies with Agilent 8800 ICP-QQQ

Fast, accurate absolute-quantification of proteins and antibodies with Agilent 8800 ICP-QQQ -

Chevron and Agilent collaborate on new multi-element crude oil analysis technology that delivers advantages in speed, cost, and safety

Chevron and Agilent collaborate on new multi-element crude oil analysis technology that delivers advantages in speed, cost, and safety -

Ask the Expert: Can I improve the chromatography of basic compounds on my older HPLC systems?

Ask the Expert: Can I improve the chromatography of basic compounds on my older HPLC systems? -

More pesticides identified using Agilent Pesticide DRS Screening GC/MSD Analyzer with new high efficiency source

More pesticides identified using Agilent Pesticide DRS Screening GC/MSD Analyzer with new high efficiency source -

Improved peak shapes for active semivolatiles with inert Agilent J&W DB-UI 8270D columns

Improved peak shapes for active semivolatiles with inert Agilent J&W DB-UI 8270D columns

Figure 1

General extractable/leachable workflow to detect a wide class of known and unknown organic/inorganic compounds that may be present in container closure systems at levels linked to risk assessment threshold levels.

Figure 2

Differential analysis using Agilent Mass Profiler Software (Rev 7.0). PCA plot for routine QA/QC (above), differential plot experiment vs. control (below).

Figure 3

An example of compound identification by high-resolution MS and PCDL research.