Access Agilent eNewsletter September 2015

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Agilent 490 Micro GC reveals contaminated and counterfeit refrigerants

By Richard Lawton

Cambridge Refrigeration Technology

Antony Atkin

Analytix Ltd

and Remko van Loon

Agilent GC Application Specialist

Since the phase-out of refrigerant R12 (dichlorodifluoromethane) for environmental reasons, the use of 1,1,1,2-tetrafluoroethane (R134a) has grown. R134a is also a component in many refrigerant blends on the market. Counterfeit R134a may contain the contaminant chloromethane (R40), which reacts with aluminum compressor surfaces used in refrigeration plants to form trimethylaluminum. Because this pyrophoric organometallic compound can ignite upon contact with air, workers need fast, accurate refrigerant composition determination. And for certification purposes, port authorities and regulatory bodies across the world require confirmation of refrigerant components. To meet these needs, the Agilent 490 Micro GC enables a reliable method to analyze refrigerants in just minutes.

Portable shoe-box-sized instrument confirms refrigerant composition

Cambridge Refrigeration Technology (CRT), based in the United Kingdom, provides industry expertise for environmental testing, refrigerated systems, insulated structures, refrigerated transport, and perishable cargo storage. One of the company’s tools in daily operations is the Agilent 490 Micro GC, which provides fast compositional analysis of refrigerant mixtures. The instrument’s dimensions and low gas consumption facilitate transportability and enable easy relocation when tests are finalized.

Figure 1. The portable Agilent 490 Micro GC accommodates up to four independently controlled channels.

The Agilent 490 Micro GC can accommodate one to four independently controlled channels; all packaged in a portable instrument the size of a shoe box (Figure 1). Each channel includes an electronic carrier gas control, micro-machined injector, narrow-bore capillary column, and micro-thermal conductivity detector (µTCD). For refrigerant analysis, the instrument is equipped with a 20-meter Agilent J&W PoraPLOT U column channel. [1] Table 1 shows the method settings for this application.

Setting |

Value |

|---|---|

|

Injector temperature |

80 °C |

|

Column temperature |

120 °C |

|

Column pressure |

165 kPa, helium |

|

Injection time |

5 ms |

|

Sample line temperature |

110 °C |

|

Sampling time |

20 s |

Table 1. Simplicity – the Agilent 490 Micro GC requires just a few settings to complete the method.

Separate all components in slightly more than three minutes

To demonstrate use of the system, a typical analysis was performed. From the refrigerant bulk gas supply, a worker collected a sample in a gas-sampling bag. The Tedlar bag was directly connected to the sample inlet of the Agilent 490 Micro GC. The system’s chip injector was flushed and loaded using the built-in sample pump. This sample pump, located behind the injector, eliminated sample carryover.

Enlarge

Enlarge

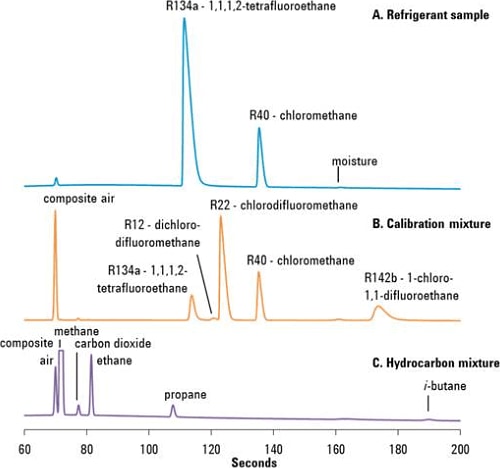

Figure 2. Speed-of-analysis: The Agilent 490 Micro GC delivers fast characterization of the refrigerant mixture and clearly demonstrates the presence of potentially hazardous chloromethane.

The 490 Micro GC, equipped with an Agilent J&W PoraPLOT U column channel, separated chloromethane from the other refrigerants in the sample in just over three minutes. A known refrigerant mixture used as a calibration mixture demonstrated baseline separation of all compounds of interest (Figure 2B). Sample analysis results for an R134a refrigerant (Figure 2A) clearly show that this refrigerant was contaminated with chloromethane. With this column type, all the refrigerants of interest elute between propane and i-butane, as shown in the comparison with a hydrocarbon mix (Figure 2C).

Rapid, easy, reliable results enable corrective action

Instead of taking a sample and waiting to a few days for lab results, CRT performs direct, on-site compositional analysis of the refrigerant gas. As a result, shipment purity is easily determined and sample integrity is secured. Out-of-spec values are directly communicated and corrective actions are taken accordingly.

Compared with sensor-based refrigerant detectors available on the market, the Agilent 490 Micro GC delivers a full characterization of the sample. It provides many more details about the refrigerant composition and – with R134a – its potentially dangerous impurities. Further details on this application can be found in Agilent publication 5991-5905EN.

Fast, portable on-site analysis

Cambridge Refrigeration Technology uses the Agilent 490 Micro GC for its speed-of-analysis. The system enables reliable and fast refrigerant compositional analysis; chloromethane impurities in refrigerant mixtures are identified in just over three minutes using an Agilent J&W PoraPLOT U column channel. This simplified instrument setup requires no specialized operator personnel. With just a handful of method parameters, the system is ready to go.

With the system’s shoe-box-size dimensions and low consumption of operating gas, portability is another reason CRT uses the 490 Micro GC. System relocation is important because refrigerated systems located around the world require periodic checkups and refrigerant refills. On-site analysis eliminates sample storage and shipment and ensures immediate availability of results. When values are outside the purity specifications, direct corrective action can occur.

If you need a portable gas analyzer that delivers fast, dependable results like these, learn more about the Agilent 490 Micro GC.

Reference

- G. A Sturrock, P. G. Simmonds, G. Nickless, D. Zwiep. “Analysis of chlorofluorocarbon replacement compounds by capillary gas chromatography” J. Chromatogr., 648, 423-431 (1993).

>> Update My Profile | Subscribe to Access Agilent | Article Directory