Access Agilent eNewsletter June 2015

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Tips and Tricks: Agilent bonded screw caps simplify lab operations, improve results, and save time and money

By Craig Douglas

Agilent Product Manager, Vials and Sample Containment

The standard screw cap with septa has been around since the invention of the sample vial. They come in different forms: cap only, septa only, or cap-septa combinations already assembled. The preassembled version is generally preferred and used by GC, LC, and CE analysts worldwide. Caps and septa will continue to play a large role in sample containment. However, field-testing has shown that, in most cases, Agilent bonded screw caps perform much better than standard non-bonded screw caps.

Drawbacks of using non-bonded caps

- Wasted time: sourcing the items separately and then assembling the pieces once delivered.

- Likelihood of errors: self-assembly can introduce contamination, poor fit, and mixing the wrong cap with the wrong septum.

- Tracking burdens: having a considerable number of part numbers to track, while not mixing up inventory.

- Other potential problems: random septum-push, septa dropping into bags, and subsequent lost analysis time.

Advantages of Agilent bonded caps

- Fewer parts to source: usually half the part numbers, with no need to purchase separate caps or septa, ever. The Agilent cap always has a septum bonded to it.

- No preassembly required: reducing the opportunity for problems, such as introduction of contamination, improper assembly, and mixing the wrong cap with the wrong septum.

- Time saving: less time is spent ordering, assembling, and troubleshooting.

- Economical: prices similar to existing products.

- Multiple options: nine choices make it easy to move from an existing screw cap to a bonded version.

Enlarge

Enlarge

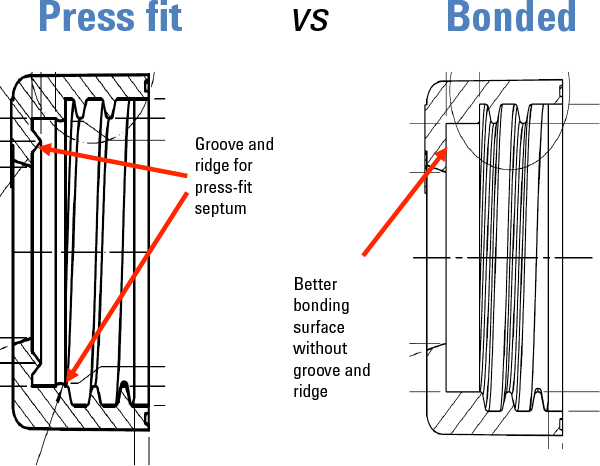

Figure 1. Cross-section drawings show the benefit of bonded septa, without groove-and ridge fixing.

Advanced design and testing

The key feature of Agilent Bonded Caps is the firm fixing of the septum. This means that the septum cannot be caught in the screw threads during assembly, or be dislodged when the cap is tightened. Figure 1 shows the weakness of the old-fashioned groove-and-ridge fixing of non-bonded septa, compared to the superior and seamless fixing of the Agilent bonded type.

We performed a great deal of orthogonal testing during product development to ensure that the bonded caps have no weakness in the short or long term. There are no adhesives or other chemicals used to hold the septum to the cap. This means a tight, lasting fit that will prevent contamination and/or leaching into a sample. Also, we performed extensive chemical/material testing to ensure that the additional annealing will not release extractables or leach into samples from the septum and/or cap material.

Be aware that Agilent bonded technology only works with polymer-based caps and not with crimp caps and tri-layer or sandwich septa. However, regardless of the cap/septum combination you use, reusing vials and caps is never recommended.

Resolving issues with vial caps and septa

To get the most from the advanced technology of Agilent bonded septa, we offer some helpful tips for fixing common issues with vial caps and septa in autosamplers (Table 1).

Issue |

Observation |

Resolution |

|---|---|---|

Coring |

Needle tears off a piece of silicone |

Ensure needle tip is sharp, or replace the needle/syringe |

Sticking |

Autosampler pulls vial out of the tray because needle sticks to septum, causing the needle to dwell inside the vial |

Occurs infrequently but can be resolved by firmware update in June 2014 for the Agilent G4513A injector (A.10.09) |

Septum pushed through |

Septum is pushed into the vial |

Proper assembly of the vial and cap is essential, so turn the cap at least a quarter turn after the top of the vial touches the septum. Also, recalibrate the autosampler so that the needle punctures the center of the cap |

Septum hard to pierce |

New septum is harder to penetrate |

Agilent septa are manufactured for consistent performance in every batch. Stiffness or hardness is related to other factors, such as the needle or the autosampler mechanism |

Needles with larger od |

I use a larger gauge needle |

Large needles can cause coring or septa push-through. Agilent recommends bonded or presplit caps for larger needles |

Table 1. Tips for fixing issues with septa.

Agilent cap and vial solutions

Our entire range of sample containment products are specifically designed to provide you with the best possible solution for your applications and samples. Competitor products simply do not meet these exact specifications, leading to costly instrument downtime and potential loss of your precious samples.

Use our online vial selection tool or request your Agilent Vial Selection Poster to save time choosing the right sample containers for your application.

>> Update My Profile | Subscribe to Access Agilent | Article Directory