Access Agilent eNewsletter July 2015

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Agilent collaborates with university to solve significant problem for oil refineries

By Wayne Collins

Agilent Global Industry Manager – Energy & Chemical

and Sue D’Antonio

Agilent Applications Chemist

One of the ways that Agilent helps our industry customers is via the development of applications to support their business needs through university collaborators. We established an important collaboration for the petroleum industry with the Department of Earth and Atmospheric Sciences at the University of Houston. The university is one of the premier institutions for this type of study, located in the heart of Houston, the ‘Energy Capital of the World.' Professor Adry Bissada is a leading collaborator. The research conducted by his group demonstrates the value of Agilent instruments in petroleum research and development.

Automated LC prevents fouling

A completely automated LC analysis of crude oil for saturates, aromatics, resins, and asphaltenes (SARA) group-type is one example of a beneficial collaboration by academia and industry. Dr. Bissada developed the strategy for the separation of SARA components in the 1990s, using a proprietary technology that he has now shared with Agilent. His SARA analysis method divides crude oil components according to their polarizability and polarity. These can be related to the effectiveness of some improved oil recovery schemes that depend on the composition of the target oil. An understanding of the resins and asphaltenes in the crude is especially significant, since these fractions can cause fouling problems during the refining process, resulting in costly maintenance and unit shutdown.

Enlarge

Enlarge

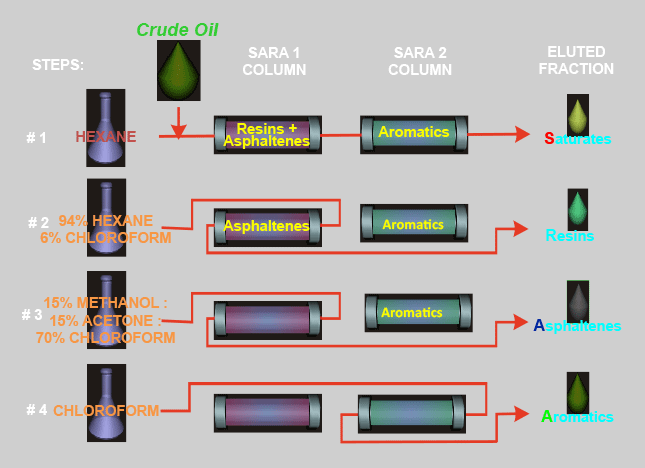

Figure 1. The steps in the separation of saturates, aromatics, resins, and asphaltenes (SARA).

Enlarge

Enlarge

Figure 2. Time-of-flight analysis of an asphaltene fraction.

Enlarge

Enlarge

Figure 3. C6H15BrClN9O in crude oil. Note the spectral presence of bromine and chlorine.

Agilent solutions for SARA analysis are ideal for use in refinery labs

The SARA analysis was duplicated in our Cedar Creek laboratory by Agilent chemists. Using the features of the Agilent 1260 Infinity Bio-inert Quaternary LC and method setup capabilities found in the Agilent OpenLAB Software Suite, valve switching and other operations were fully automated to make the method ideal for easy use in refinery labs. Each of the fractions can contain hundreds or thousands of individual compounds and so exact quantitation is not possible. However, two different approaches, using the total peak areas from the chromatograms of each fraction, provide semiquantitative information that is sufficient for our purposes. These approaches make use of the total area of all peaks or selected peaks, so that chromatographic resolution is not important.

The steps in the separation are shown in Figure 1. An additional benefit of the method is that the aromatic, resin, and asphaltene fractions can be further analyzed by time-of-flight mass spectrometry, as shown in Figure 2.

What’s more, we can obtain valuable information about halide compounds that promote corrosion in the refinery equipment, or metal compounds that provide important clues to the geology of petroleum exploration. For example, Figure 3 reveals the spectral presence of bromine and chlorine in a crude oil sample.

Agilent is committed to the constant exploration of new ways to solve problems associated with the discovery and enhanced recovery of resources, as well as for improvement of processing technologies.

Fast, accurate, and powerful petrochemical analysis with Agilent Solutions

Agilent has more than 40 years of collaboration with ASTM International in the creation and management of standardized analysis procedures. Furthermore, many have been developed on Agilent instruments including GC, LC, MS, FTIR, and GC/MS. Our portfolio features integrated workflow and automation solutions for enhanced efficiency, from sample preparation through analysis to report generation, that results in cost savings. We also continue to monitor emerging requirements and trends to introduce the new methods needed by the industry through our partnership with ASTM International.

Explore the Agilent world of fast, accurate, and powerful petrochemical analysis. Visit our website for the latest information on Agilent’s full line of solutions for energy and chemicals.

>> Update My Profile | Subscribe to Access Agilent | Article Directory