Access Agilent eNewsletter August 2015

>> Update My Profile | Subscribe to Access Agilent | Article Directory

More LC efficiency – More free time

By Helmut Schulenberg-Schell

Agilent Liquid Phase Separations

Analytical laboratories are constantly asked to produce data of higher quality while lowering costs and increasing sample throughput.

With the arrival of UHPLC column technology a decade ago, liquid chromatography (LC) can provide more robust results in less time. Still, many laboratories are faced with the challenge of managing smooth migration to the latest methodology and to continue their daily business without major disruption. Scientists, routine operators, and lab managers have varying perspectives on ways to raise efficiency in the laboratory.

Enlarge

Enlarge

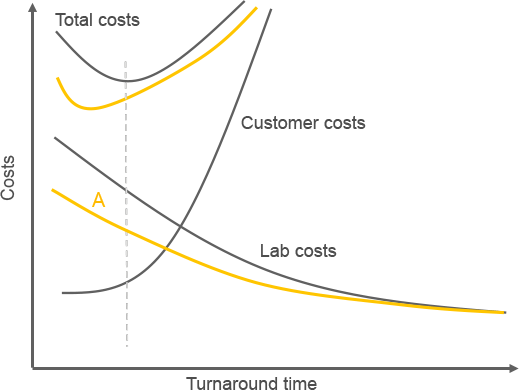

Figure 1. Reduction of lab costs leads to lower total costs of a fabricated product – preferably at higher throughput.

In Agilent’s new series of webinars on-demand, six speakers explain how they address the efficiency situation (Figure 1). This article summarizes their thoughts.

Analytical efficiency – one assay instead of two

Laboratory scientists are frequently required to improve separation and detection performance. Recent advances in instrumentation and chemistries give users a myriad of options that can be difficult to untangle. Improvement in analytical efficiency is no longer as simple as changing one parameter, such as LC column particle size. Real improvements in analytical efficiency require a ‘systems perspective’ to identify and quantify compounds at the required limits of detection.

In a recent webinar, Professor Dwight Stoll explains how to improve LC peak capacity and increase resolution by critically reviewing a UHPLC instrument setup. As an expert in the field, he shares his view on two-dimensional liquid chromatography (2D-LC), and how modern instrumentation avoids mistakes during daily routine work with these systems.

In the second portion of this webinar, Dr. Udo Huber at Agilent reveals how highest sensitivity and linearity enable detection of compounds with widely different concentrations in a single analysis. For the first time, an evaporative light scattering detector (ELSD) with a 90-fold wider dynamic range is applied to analyze impurities and main compounds in a single assay.

Instrument efficiency – automated LC methods development

Continuous improvement of manufacturing processes is essential to keep pace with a dynamic business climate in today’s manufacturing world. At the same time, consistent quality of products is mandatory to ensure customer satisfaction. Rapid automated method development enables a timely response to unexpected changes in the manufacturing process.

Two more webinars provide insights that reduce method development time. Dr. Matthias Pursch at Dow Chemical shares examples of rapid method development to demonstrate the benefits of automation. Dr. Anneke Mühlebach at Agilent in Waldbronn, Germany describes how the day-to-day user can save time and how to significantly decrease time-to-result in a method development environment.

Lab efficiency – save greater than 30% cost per sample

Lab efficiency requires a holistic view that encompasses the expenses incurred and the amount of work produced. In most analytical labs, the largest expense is labor and the second largest is instrument purchases. Unfortunately, labor and instruments are the least elastic of all lab resources. Therefore, an efficient lab manager successfully balances personnel and equipment so that each person and each instrument is fully productive. Two additional webinars provide useful tips.

In the first, Dr. Ken Lewis, Chief Executive Officer at OpAns, LLC shares insights and solutions used by the contract research laboratory that he manages in Durham, North Carolina. His workload can vary significantly and short turnaround times are essential to win business. Modern LC solutions have made his staff more productive and have increased instrument utilization. Examples include:

- Increased output with new autosampler capabilities

- Increased productivity from total system integration

- Improved user experience

Enlarge

Enlarge

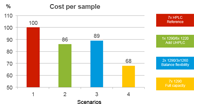

Figure 2. Replacing HPLC instruments 1:1 with Agilent 1290 Infinity solutions reduces cost per sample by 32% (model study with Dr. Kreiss/Klinkner & Partner).

In the final webinar, Dr. Helmut Schulenberg-Schell at Agilent demonstrates how Agilent’s stepwise upgrade strategy enables full compatibility among various data systems and instrument generations. He gives examples that show how to streamline the utilization of your instruments and save more than 30% on cost per sample (Figure 2).

Do more with less

Many labs face the daunting task to produce better results, faster, with less money invested. If your lab must generate high-quality, reliable LC data more rapidly and at lower cost, learn how the new Agilent 1290 Infinity II LC can enable your success. For more information, contact your Agilent Representative today.

>> Update My Profile | Subscribe to Access Agilent | Article Directory