Access Agilent eNewsletter, March 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Innovative 4300 FTIR takes as big leap forward in handheld technology

By John Seelenbinder Ph.D

Agilent Mobile FTIR Marketing Manager

and Alan Rein Ph.D

Agilent Business Development Manager

Agilent, a pioneer in the field of handheld Fourier transform infrared spectroscopy (FTIR), is developing revolutionary instrumentation for non-destructive measurement in a broad range of industrial markets including composites, coatings, polymers, geology, art and historical objects, food, and agriculture.

A handheld FTIR allows the user to take the instrument directly to the object requiring analysis, regardless of its location or size – eliminating the need to transport an object or sample to a traditional lab. Measurements can be made in situ and in real-time, enabling greater flexibility in understanding what and where to measure. It also means that it is not necessary to excise a sample from the object, making handheld FTIR a truly non-destructive testing solution.

Figure 1. Designed with ergonomics in mind, the new 4300 Handheld FTIR is smaller and more lightweight, allowing analysts to take it to any object in virtually any location for non-destructive testing.

Now Agilent is pleased to introduce the latest innovation in its long line of class-leading mobile spectroscopy products – the 4300 Handheld FTIR.

Designed to meet unique challenges

Development of handheld FTIR technology provides some unique challenges. The instrument must be lightweight, small, battery operated and intuitive to use, while still providing the highest quality data required for meaningful decisions. Agilent’s first generation of handheld FTIR spectrometers – the 4100 ExoScan and 4200 FlexScan – was a great leap forward in transportable size and weight. Because these two instruments proved to be so valuable, customers requested that we work to develop an instrument that was even lighter, and more compact. The result was development of the Agilent 4300 Handheld FTIR – lighter, better balanced and easier to use than Agilent’s earlier models (Figure 1).

Better ergonomics lead to better results

When developing a handheld instrument, good ergonomics plays a role just as important in the overall performance of the FTIR as more traditional measures, such as signal-to-noise or optical throughput. To obtain quality data, users must be able to easily access the sample location and then comfortably hold the instrument for the duration of measurement. Even though a measurement typically can be taken in less than 30 seconds, an instrument that is not only lightweight but also well-balanced makes it easier for users to obtain good data.

Ergonomic standards recommend that handheld tools weigh less than 2.3 kg and have the center of gravity located near the center of the grip [1]. The Agilent 4300 Handheld FTIR meets both of these requirements, is 35% lighter than our earlier handheld systems, and provides performance that is equal to that of the earlier handheld systems.

How were we able to retain the signal-to-noise and resolution while reducing the size of the FTIR? We accomplished it by carefully optimizing the optical train. Each component in the Agilent 4300 FTIR is designed to minimize optical aberrations. The result is a more efficient optical system. Here’s why: even though component miniaturization reduces the size of the optical aperture and provides less light than previous models, the optimized optics and shorter beam path deliver a greater percentage of light to the sample and consequently to the detector.

Figure 2. Go directly to the sample site from museums to mountainsides for reliable results in situ.

Enlarge

Enlarge

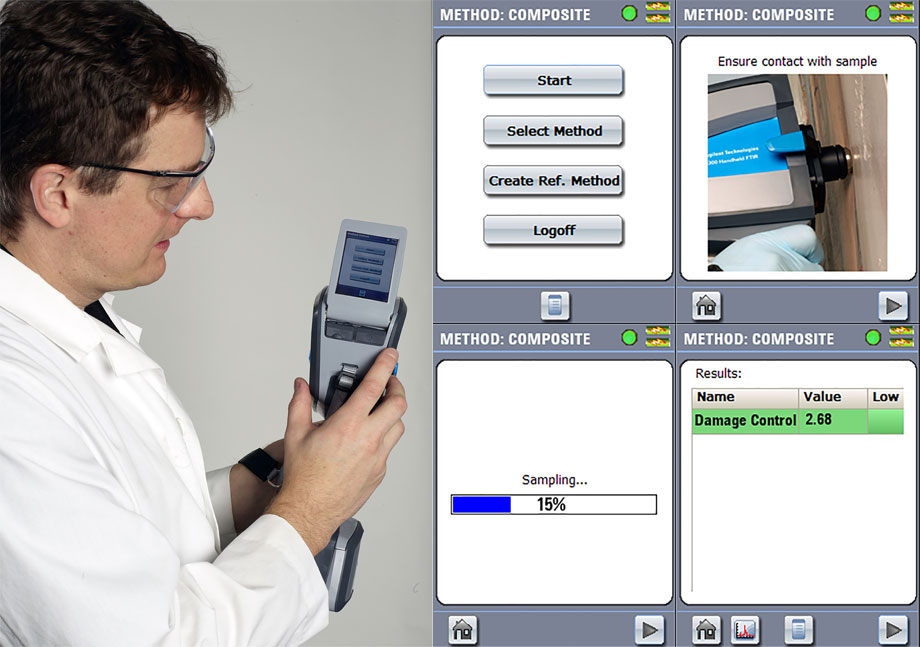

Figure 3. MicroLab Mobile software runs the system through the embedded computer in the 4300 Handheld FTIR.

Figure 4. Multiple sample interfaces that attach instantly are available for analyzing different sample types in the field.

Enlarge

Enlarge

Figure 5. The new 4300’s configuration allow Aerospace applications to be executed with ease without destruction to high value materials.

Two variations let you choose greater flexibility or greater speed

There are two variations of the Agilent 4300 Handheld FTIR. You can choose from the flexible Deuterated Triglycine Sulfate (DTGS) infrared detector or the high-performance, thermoelectrically cooled Mercury Cadmium Telluride (MCT) detector. The DTGS provides the greatest measurement flexibility available, enabling you to collect data over the full infrared frequency range from 5000 to 650 cm-1. It is the ideal choice for a wide range of applications. The MCT detector has a smaller frequency range of 5500 to 1100 cm-1, but offers both faster measurement time and a 20% improvement in the signal-to-noise ratio making it ideal for those unique applications where it is essential to quickly take a large number of readings across the surface of an object or area of interest.

Rugged reliability for years of field measurements

There’s virtually no limit to where you can effectively take the rugged Agilent 4300 FTIR because it is specifically designed for field measurement (Figure 2). Its miniaturized interferometer is permanently factory aligned. It has a patented design with a symmetrical optical layout and is made from rugged materials that can stand up to long hours of use. Furthermore, the system operates from 0 to 50 °C, providing nearly identical performance over the entire range. Combine all these features with its smaller size and a short optical path that is unaffected by shock or thermal gradients and you have a system that will return reliable results for many years. No matter where you take it.

Outstanding ease of use thanks to integrated software and interchangeable interfaces

Agilent’s 4300 Handheld FTIR provides real-time answers in a wide range of applications making it easier than ever for you to make critical decisions. The 4300 FTIR has an integrated computer that runs method-driven Agilent MicroLab Mobile software (Figure 3). This software instructs users on each step of the data collection and presents an actionable final result. All of the data analysis is integrated into the method, so the user can make quick decisions without need for further data analysis.

The 4300 FTIR has a flexible platform that allows you to effectively measure many different types of samples including objects that are reflective, non-reflective, infrared absorbing or scattering. To handle this range of applications, the system has five different sample interfaces that are instantaneously interchangeable, and each provides its own specific means of delivering the light to the sample (Figure 4). These interfaces have RFID identification, providing seamless integration between the sample interface and specific software methods, so it’s easy for you to read – and keep track of – your measurements.

A legacy of excellence in portable instrumentation

The 4300 Handheld FTIR is the latest development in Agilent’s successful line of FTIR spectrometers. It is both a leap forward and the culmination of years of innovation. The Agilent 4300 FTIR provides the performance previously found only in full-size FTIRs – at a size, weight and ergonomic form factor that make it ideal for mobile, nondestructive testing. The DTGS detector is a highly flexible option in the field, while the MCT detector enhances both speed and performance to provide outstanding real-time measurement capabilities. These new capabilities will not only enhance the overall user experience, but also open up a range of new applications for handheld FTIR spectroscopy (Figure 5).

Take a moment now to learn more about how the Agilent 4300 FTIR can open up a whole new world of testing opportunities and locations. Then talk to your Agilent Representative about how you can put the new 4300 Handheld FTIR to work in your operation today.

- Assessment of the Ergonomic Quality of Hand-held Tools and Computer Input Devices, Helmut Strasser, IOS Press, Jan 1, 2007.

>> Update My Profile | Subscribe to Access Agilent | Article Directory