Access Agilent eNewsletter, June 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Positive material identification of polymers using Agilent mobile FTIR spectrometers

By John Seelenbinder Ph.D.

Agilent Global Marketing Manager – Mobile FTIR

and Alan Rein Ph.D

Agilent Global Business Development and Commercialization – Mobile FTIR

Progress in the development of advanced materials has resulted in an enormous array of polymer, plastic, composite, and elastomer products, components, and objects. Classes of these materials have similar structure, but small deliberate changes in formulation cause these compounds to have different use and wear properties. You need analytical methods and technology that can rapidly qualify and verify composition of these materials. Growth in globalization of component sources makes it critical to ensure authenticity and to detect counterfeit, mislabeled, or out-of-specification polymeric material and components.

Positive material identification (PMI) is necessary, and a particularly useful technology for analysis of these advanced materials is Fourier transform infrared spectroscopy (FTIR). The recent availability of Agilent compact and portable FTIR analyzers adds a new dimension to the analysis of polymers, plastics, elastomers, and composites.

Figure 1. The Agilent 4300 Handheld FTIR (left) and 4500 Series Portable FTIR Spectrometers (right) are true nondestructive analyzers that allow you to measure objects in situ, regardless of size and shape.

No need to destroy the sample

Now, you can bring the analyzer to the material or object for chemical identification. FTIR becomes a truly nondestructive method, and objects that are too large, too valuable or for which a sample cannot be excised without affecting performance, can now be measured without compromise.

Agilent’s compact, portable FTIR analyzers are equipped with novel software and sample interfaces that make method execution easy and optimize analysis results. You can accomplish PMI with three different types of data analysis techniques:

- Measurement of a polymeric material to verify its identity via its overall chemical structure.

- Determination of the chemical composition of a particular polymer or polymer component to confirm that it meets its required use-specification.

- Measurement of the concentrations of specific compounds contained in the polymer to ensure that they are within specification for physical performance or consumer safety purposes.

Each of these examples requires a different analytical approach. While Application Note 5991-4122EN demonstrates how the Agilent portable and handheld FTIR systems nondestructively accomplish all three analysis scenarios, this article focuses on the determination of chemical composition.

Discriminant analysis confirms how well a material matches specifications

A library search of an FTIR spectrum provides a simple methodology for many routine identification needs. But in the case of polymeric seals, you require a more detailed analysis to differentiate, identify, and authenticate materials. The seals may have similar FTIR spectra but still have performance variations that result from slight disparities in formulation. When investigating a set of materials to determine how well an individual example meets pre-established specifications, the Agilent FTIR systems use a method based on discriminant analysis.

In this case, multiple spectra are stored that represent a specification set for an individual class of material. The instrument uses partial least squares or principal component analysis to determine commonality of a sample with the overall sample set in the class. Simply put, it is a powerful means to quickly determine whether a sample is “good or bad”, counterfeit or authentic. Agilent’s MicroLab software displays the identity of the material, and conditional reporting enables a pass/fail determination.

Enlarge

Enlarge

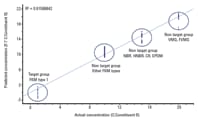

Figure 2. Model accurately classified FKM Type 1 elastomers based on chemical composition.

Enlarge

Enlarge

Figure 3. Results show a positive confirmation of FKM Type 1 elastomer based on the calibration shown in Figure 2.

O-ring types classified for on-site analysis

As an example, we created a discriminant model to identify FKM Type 1 O-rings, which are used as seals in the petroleum industry. The model used a partial least squares discriminant analysis (PLSDA) technique.

We collected a single calibration set that contained eight different categories of FKM materials. These materials all have very similar formulations; however, each category has unique properties so it is important to distinguish the FKM types.

To obtain a good separation between the various FKM groups, the target group of FKM Type 1 was assigned a value of 1, while spectra of samples from the seven other groups, including both FKM and other elastomers, were assigned values from 10 to 20, depending on the degree of chemical differences from the target group. This range of values allowed the model to accurately distinguish FKM Type 1 from other FKM types that incorporated other kinds of elastomers. The classification results using cross-validation are shown in Figure 2.

We incorporated the calibration shown above into a Microlab PC method. We used the conditional reporting feature to display a message of “Confirmed FKM Type 1” for samples within the target group (Figure 3) and the message “NOT FKM TYPE 1” for samples outside the target group.

Positively identify materials with on-location analyses

The need to identify and verify specifications, ensure authenticity, and detect counterfeits in polymer materials is of significant global importance in manufacturing industries. Agilent 4300 Handheld FTIR and 4500 Series Portable FTIR Spectrometers use three different analytical approaches to aid positive material identification. Whether you need spectral search, discriminant analysis, or quantitative analysis to verify the identity and specifications of a material, the rugged Agilent spectrometers meet the required need.

If you must positively identify materials and you want to make FTIR measurements where and when needed, explore the complete Application Note 5991-4122EN for more information. Agilent Technologies would like to thank Precision Polymer Engineering for providing sample material for this evaluation as well as valuable input regarding elastomer usage.

>> Update My Profile | Subscribe to Access Agilent | Article Directory