Access Agilent eNewsletter, June 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

The Agilent Self Tightening Column Nut – engineered for value

By Phil Stremple

Agilent Chemical Analysis Buiness Group

When engineers at Agilent create a new product, they aim to solve customers’ problems and challenges. A good example is the new Agilent Self Tightening Column Nut for GC systems. The nut was developed to dramatically reduce a long-time problem – leaking column connections. In addition to the unique construction, which uses spring-driven pressure to maintain a tight seal, there were other important considerations that factored into the design of the new nut.

Better durability equals better ROI

Typical column nuts are made from brass, a material that is prone to crack and bend after repeated use. The Agilent Self Tightening Column Nut is constructed from rugged stainless steel, which is much more durable than brass. This durability means that the new nut essentially pays for itself after 38 or 39 column changes, compared to changing column nuts much more frequently when the nuts are made from brass. We developed this simple equation to calculate how long it takes for the new nut to pay for itself…

$85 (STCN cost) + n/$5.49 (short ferrule cost) = $12 (standard nut cost) + n ($6.19 long ferule cost + $0.62 nut cost per column)

…where n = payback time in weeks. Solving for n reveals that it takes just 11 weeks to recoup the cost of the Self Tightening Column Nut in normal lab use. The unique stainless-steel construction of the nut delivers a leak-free connection without upgrades, adaptors, or special tools. It is especially well suited for oxygen-sensitive detectors, such as mass spec and electron capture.

In addition to a vastly improved lifetime, this new nut saves valuable time in the laboratory. No special tools are needed for installation into an inlet, detector, or MS interface. Since the nut is self tightening, chemists and technicians do not waste valuable time checking for and correcting leaks.

Enlarge

Enlarge

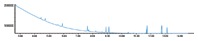

Figure 1. Air leaks and unstable baseline after 25 injections with standard brass column nuts.

Enlarge

Enlarge

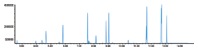

Figure 2. No air leaks and stable baseline after 400 injections with Agilent Self Tightening Column Nuts.

Performance matters

When attaching the column to the inlet, overtightening can cause soft ferrules to extrude into the fitting, leading to contamination of the flow path or creating active sites. Applying too much force on column nuts can also damage instrument fittings, resulting in expensive repairs – especially at the mass spec interface. Agilent’s Self Tightening Column Nut with easy finger-tight design requires no retightening and is ideal for use with short graphite/polyimide ferrules, and with inlet, detector, and MS transfer lines, even at high temperatures over hundreds of injections.

Figure 1 shows the effect of using standard column nuts, after 25 injections. The baseline became unstable because of leaks at column connection points. Conversely, when we used the Self Tightening Column Nut, Figure 2 shows a marked improvement in baseline stability with no air leaks, even after 400 injections.

Better GC connections for better GC

Engineering for value means creating better products that save you time – exactly what the small but revolutionary Agilent Self Tightening Column Nut accomplishes. To discover more solutions for creating and maintaining leak-free GC connections, download The Right Connections Make All the Difference or your free copy of our new wall chart on Making Better Column Connections. For additional reading on this application see Agilent publication 5991-3612EN.

>> Update My Profile | Subscribe to Access Agilent | Article Directory