Access Agilent eNewsletter, June 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Maximize recovery rates in preparative LC with Agilent flow splitter kits

By Pierre Penduff

Agilent Application Chemist, Liquid Chromatography, Life Sciences Group

In peptide synthesis, non-aromatic amino acids remaining after reaction cannot be monitored by a conventional UV detector because they have little or no chromophore. Detection by evaporative light scattering (ELSD) or mass spectrometry is therefore essential. The Agilent 1260 Infinity ELSD with flow splitter kit provides the simplest way to monitor or trigger the collection of target compounds, without the risk of collecting impurities at the same time.

Enlarge

Enlarge

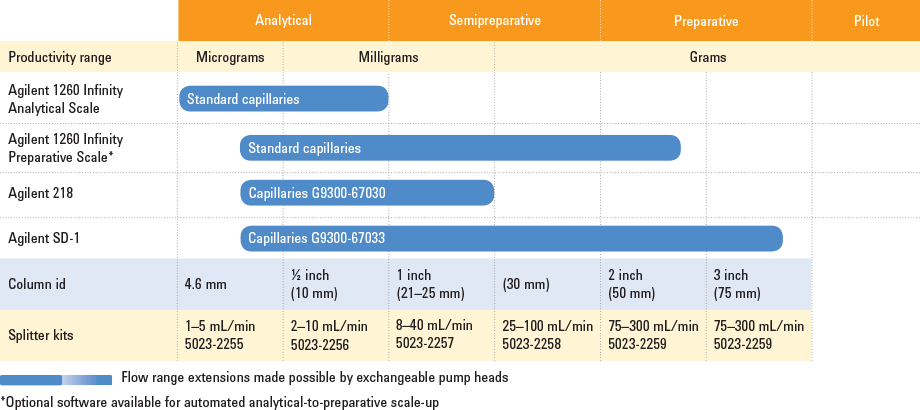

Table 1. Splitter and capillary kits available for the different flow rates of Agilent purification systems.

Agilent splitter kits divide the preparative flow between the ELSD and fraction collector – after the column and UV detection. The main flow goes to the fraction collection and the split flow to the ELSD. The split is achieved by flow restrictions that are generated by system backpressure. Splitter kits are designed for preparative High-Performance Liquid Chromatography (HPLC) applications with flow from 1 to 300 mL/min. Thus, different splitter kits are required for different flow rate ranges and systems (Table 1).

Collecting a sample mixture can be done by ELSD or UV peak-based collection methods. In this article we highlight a couple of examples which demonstrate the performance capabilities of Agilent ELSD systems with splitter kits – focusing on reproducibility, recovery, and purity.

Enlarge

Enlarge

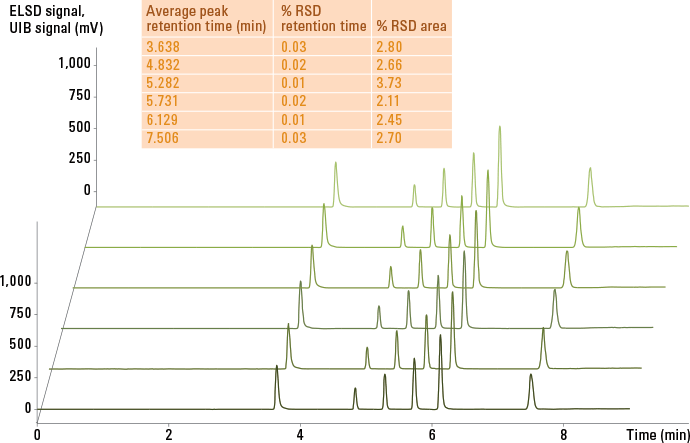

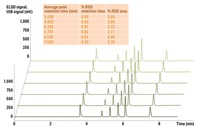

Figure 1. Signals from the universal interface box of six injections, and resulting retention times and area precisions.

Maximizing recovery of your samples

We purified a drug-like sample mixture containing a target compound without chromophore. To prove the reliable performance of the splitter, the standard deviation of the retention time and peak area were calculated. The Agilent 1260 Infinity Preparative-scale Purification System, combined with the 1260 Infinity ELSD, gave highly reproducible purification results, with an average RSD of 0.02% for retention times and 2.74% for average peak area precision (Figure 1).

Typical recovery and purity of the system were determined by loading the Agilent ZORBAX SB-C18 Prep HT Cartridge (21.2 x 100 mm, 5 µm) with a 750 µL injection of sample mixture. Recovery was 91% and purity was 99% for this purification.

Optimizing your prep system

We’ve seen how the simple splitter solution can be used to enhance detection for purification of small molecules or non-UV chromophores. However, other parameters also require optimization to ensure the best reliability and purity of the collected fractions. For example, delay time between the detector and the fraction collector needs to be measured. This delay is the difference between the time the compound is monitored in the detector and the time when this compound reaches the diverting valve of the fraction collector. Correct measurement of delay time is an important step in system optimization. The procedure is automated on 1260 Infinity fraction collectors using Agilent LabAdvisor software.

Enlarge

Enlarge

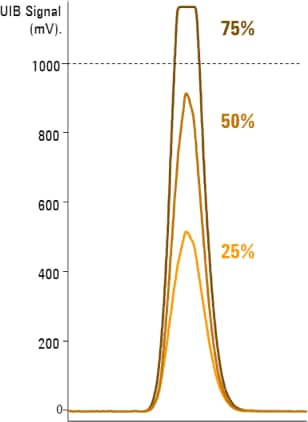

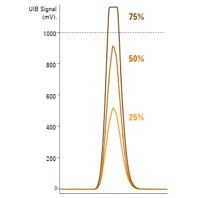

Figure 2. Overlay of ELSD signals at 25%, 50%, and 75% of the maximum light intensity from three injections (250 µL each) of a sample mixture.

Adjustment of peak-based collection can also be optimized with respect to the peak shapes of the compounds purified and loading of the injected mixture. This step involves preliminary work on the analytical column or by performing a pilot run to define threshold, upslope, and downslope.

Finally, saturation of the detector can occur, due to the high sensitivity of the ELSD under high concentrations. This sensitivity can be decreased on the Agilent 1260 Infinity ELSD by reducing the light intensity. The upper threshold of the fraction collector can also be adjusted below the saturation of the detector to prevent slope triggering at the saturation of the detector. For the ELSD, as shown on the Figure 2, an upper threshold of 1000 mV can be used.

Further information on the Agilent ELSD splitter can be found in Agilent Technical Overviews and the Agilent Splitter Kit installation manual.

High loadability for your prep samples

Whether you are scaling up a routine analytical method, or maintaining precise separations throughout every phase of production, Agilent’s wide array of preparative and process columns and bulk media are designed for high loadability in many particle sizes and phases. In addition, our family of ELSD supplies and replacements deliver the highest quality and levels of performance across a wide spectrum of ELSD applications.

Comprehensive solutions for LC purification

Agilent offers a comprehensive portfolio of solutions for LC purification, including the new workflow-based Agilent 1260 Infinity Automated LC/MS Purification System that provides pure fractions without method development or scale-up work, thus meeting the demands for secure compound confirmation and high throughput. The new Agilent 1260 Infinity Automated LC/UV Purification System, a truly automated LC/UV-System, also provides pure fractions without method development or scale-up work – with minimum investment and training. To learn more, take a moment to view our informative videos on evaporative light detection located in the LC Detector videos tab.

>> Update My Profile | Subscribe to Access Agilent | Article Directory