Access Agilent eNewsletter, September 2013

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Agilent 1290 Infinity LC System saves significant cost and time for analytical quality control

By Dr. Vogelsanger

Nitrochemie AG, Wimmis, Switzerland

and Christian Gotenfels

Agilent Senior Product Manager, UHPLC Systems

Customer profile:

Nitrochemie AG, Wimmis, Switzerland

As a subsidiary of Rheinmetall Defence, the Nitrochemie Group forms the Propellants Division. The core competencies of Nitrochemie are the development and manufacture of propellants for military and civil sector requirements and the manufacture of chemical intermediates and additives for silicone sealants.

Every analytical quality control (QC) laboratory today is under constant pressure to increase productivity and the Nitrochemie company is no exception. Responsible for the quality control of chemical products as well as analyses of production wastewater according to environmental regulations, Nitrochemie’s QC laboratory was faced with the challenge of reducing both cost per analysis and turnaround times while increasing sensitivity of the wastewater analysis.

To accomplish these objectives, laboratory manager Dr. Vogelsanger evaluated several UHPLC systems, including the Agilent 1290 Infinity LC. He selected the Agilent system because of the large power range and low delay volume of the pump, and the high sensitivity of the detector.

Substantial benefits

With the introduction of the Agilent 1290 Infinity LC, Nitrochemie has:

- Cut the total cost of ownership by an estimated 100,000 Swiss Francs (about 95,000 U.S. dollars) per year

- Reduced analysis times from 10-20 minutes to less than two minutes

- Lowered the limit of detection for the wastewater analysis by a factor of 100

The most notable benefit was the laboratory’s ability to replace five older conventional HPLC systems with one Agilent 1290 Infinity UHPLC system.

Enlarge

Enlarge

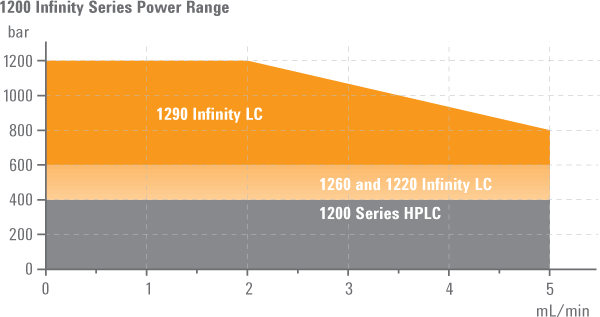

Figure 1. Power range of the 1290 Infinity LC is the widest available from Agilent, combining ultrahigh pressure up to 1200 bar and high flow rates up to 5 mL/min for maximum chromatographic performance, compatibility, flexibility and investment protection.

Selection criteria

The following information about the Agilent 1290 Infinity LC helped Dr. Vogelsanger to select the Agilent system in preference to the ostem in preference to the oated:

- Large power range of 1200 bar at 2 mL/min and 800 bar at 5 mL/min (Figure 1), and the low delay volume of less than 100 µL of the Agilent 1290 Infinity Binary Pump

- High sensitivity of the Agilent 1290 Infinity Diode Array Detector, which is 10-fold higher than the predecessor model

- High precision of injection volume of the Agilent 1290 Infinity Autosampler for both small and large volumes without loop changes

- Recommendations received from other users, citing the Agilent 1290 Infinity LC’s ease-of-use, robustness, and low maintenance cost in combination with the possibility that most parts can easily be replaced by laboratory personnel

Challenges of introducing UHPLC

When introducing UHPLC into the laboratory, several challenges had to be solved. The change from “clumsy” 5 µm HPLC columns to state-of-the-art sub-2-µm column technology required much more attention to the use of clean and/or microbe-free water and solvents and avoidance of contamination of the injection system. All connections had to be made very carefully to avoid a massive increase of delay volume and thus a reduction in resolution. The high sensitivity also meant that many trace components of the sample became visible – meaning that the gain in sensitivity could only be utilized if the “additional” peaks were separated from the analyte peaks.

The main challenge, however, was to cope with the unexpected rapid increase of backpressure when using sub-2-µm columns. This effect was caused by plugging of the column inlet frits, presumably by the presence of colloidal polymeric material from the specific sample matrix (nitrocellulose-based propellants). This problem was solved by simply changing to columns made from semi-porous material, such as the Agilent Poroshell 120 columns. These column types have coarser inlet frits, which makes them less susceptible to “dirty” samples.

Once these challenges were overcome, the Agilent 1290 Infinity LC not only met, but even exceeded Dr. Vogelsanger’s expectations.

Increased laboratory productivity

With the Agilent 1290 Infinity LC, Dr. Vogelsanger was able to reduce analysis times for several analytical methods from 10-20 minutes to less than two minutes. These time-savings allowed him to replace five of the laboratory’s older conventional HPLC systems with just one Agilent 1290 Infinity LC. Together with the dramatic reduction in solvent usage, the total cost-of-ownership savings are estimated to be 100,000 Swiss Francs (about 95,000 U.S. dollars) per year.

In addition, his customers now benefit from shorter turnaround times by receiving results of their samples one day earlier.

Further, the limit of detection for the wastewater analysis was reduced by a factor of 100 because of the superior sensitivity of the Agilent 1290 Infinity Diode Array Detector; this allowed in-house evaluation of compliance with the respective regulations.

large

large

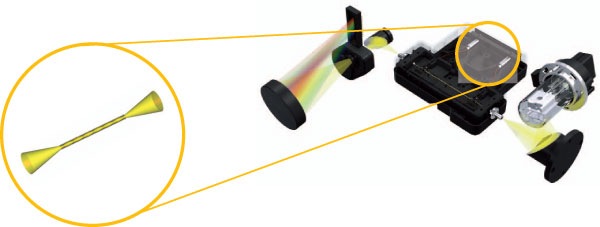

Figure 2. The optical design of the Agilent 1290 Infinity DAD is based on the Max-Light cartridge cell with 60 mm optical path length. This new cell technology increases dramatically the light transmission by utilizing the principle of total internal reflection in a non-coated fused silica fiber.

To utilize the potential of the new instrument technology (shown in Figure 2), several analytical methods were completely redesigned. In one case, it was possible to replace four different HPLC methods used to assess the contents of four target compounds within the same sample with only one UHPLC method. The HPLC methods used different chemical digestion procedures, followed by isocratic separation with different column materials (C18 and CN), and detection with both UV and evaporative light scattering detectors. The UHPLC method is based on an optimized chemical digestion, gradient separation on standard C18 columns, and UV detection using the wider detector linearity of the Agilent 1290 Infinity Diode Array Detector.

Realizing the future

With just one LC system to maintain instead of five, Dr. Vogelsanger is looking forward to significantly lower service costs in the future. Further, the high power of the Agilent system will be able to cope easily with analytical challenges that arise from new product developments within the enterprise.

Like Dr. Vogelsanger, you can achieve optimum LC performance at lower cost per analysis. Learn how much you can save when you transfer your method to an Agilent 1290 Infinity LC System. Also try Agilent’s new method transfer and cost calculation tool, where you can make your own calculations and see the results immediately.

>> Update My Profile | Subscribe to Access Agilent | Article Directory