Access Agilent eNewsletter November 2015

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Advanced LC method development in slim single Agilent 1290 Infinity II stack

By Anneke Muehlebach

Agilent Global Product Manager, Analytical LC

LC method development can be quite time-consuming when a wide variety of columns, solvents, and temperatures must be tested to find optimal separation conditions. An automated LC system accelerates method development, but is typically set up as a two-stack configuration that occupies valuable bench space. With the Agilent 1290 Infinity II LC system, advanced LC method development is now possible with fewer modules than before: A slim single stack with small footprint (Figure 1) saves bench space and enables more than a 1000 different separation conditions. These conditions are all easily accessible with a new version of the Agilent Method Scouting Wizard.

Figure 1. The single-stack Agilent 1200 Infinity Series Method Development Solution uses bench space efficiently.

Figure 2. The Agilent 1290 Infinity II Multicolumn Thermostat equipped with eight column selection valves and Agilent A-Line Quick-Connect fittings for rapid, trouble-free column exchange.

Fast, straight-forward method development

Ultra high performance liquid chromatography (UHPLC), a key analytical technology in pharmacology and chemistry, efficiently separates compounds. Because separation of compounds is determined by the interaction of the analyte molecules with stationary and mobile phases, identification of suitable conditions for optimal separation can be quite a demanding task. The possible combinations of crucial parameters like solvent type, column type, temperature, and gradient composition are almost endless. Based on the advanced hardware and software of the Agilent 1290 Infinity II LC family, the Agilent 1200 Infinity Series Method Development Solution simplifies and accelerates generation of sequences that systematically vary all crucial method parameters.

The Agilent 1290 Infinity II Multicolumn Thermostat (MCT) is the core module in the method development solution that optimizes efficiency of method development. Now a single MCT offers capacity for up to eight columns – each with individual low-dispersion heat exchangers for precolumn solvent heating (Figure 2). These heat exchangers enable solvent cooling or heating in a broad temperature range from 4 °C (about 20 °C below ambient temperature) to 110 °C. Agilent A-Line Quick-Connect fittings allow a fast exchange of columns. You can successfully address challenging applications like analysis of thermally labile compounds, temperature-sensitive chiral separations, or fast chromatography at elevated temperatures.

For optimized separation, easily explore eight columns

An Agilent 8-column selection valve – applicable up to 1300 bar – allows you to select between up to eight columns without the need to replumb. In contrast to previous thermostatted column compartments, the Agilent 1290 Infinity II MCT is equipped with a flexible door flap. When opened to 90°, you can use the door as a “little desk” to facilitate column installation without the need for a “third hand.” For better access, you can open the door flap to 180° or even remove it completely.

Easy set-up of sequences with the Agilent Method Scouting Wizard

The Agilent Method Scouting Wizard (MSW) is a software add-on to Agilent OpenLAB CDS – ChemStation Edition. MSW helps you set up methods and sequences for easy and logical method scouting using an Agilent 1200 Infinity Series Method Development Solution. A sequence is created that has all possible combinations of available columns, solvents, predefined gradients, and predefined temperatures. The Method Scouting Wizard automatically generates all steps to flush the system with any required solvents, performs column equilibration procedures, and can store columns in predefined storage solvents. It intelligently uses waste and/or available bypass lines to allow fast flushing procedures. To save valuable time and solvents, it sets up a workflow that requires a minimal number of steps.

Enlarge

Enlarge

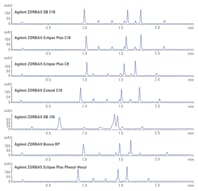

Figure 3. UV chromatograms show separation of the test mixture. To identify optimal separation conditions, we automated the investigation of seven different stationary and mobile phases.

Example demonstrates speed of method development

For a method scouting campaign, we applied seven columns of 50 mm length (2.1 mm internal diameter, 1.8 µm particle size) in combination with three aqueous and four organic mobile phases. We used one position of the column-selection valve as a bypass to flush the system quickly when a solvent change was necessary. In addition, we performed temperature scouting at 30, 40, 50, and 60 °C. A generic gradient was applied during the complete campaign. We created the sequence using the Agilent Method Scouting Wizard, which resulted in a total of 166 sample injections as well as corresponding flush and equilibration runs. This flexible system enabled rapid identification of optimal separation conditions for a complex sample.

Choose LC solutions that match your needs

Agilent offers a wide range of tools and solutions for automation of virtually any liquid chromatography application. Whether you must increase sample throughput, accelerate method development, automate sample preparation, or solve challenging applications, Agilent’s highly modular approach provides the flexibility you need to succeed. To discover more, contact your Agilent Representative, who can help you identify the right tools for your application.

References

- “Automated Scouting of Stationary and Mobile Phases Using the Agilent 1200 Infinity Series Method Development Solution”, Application Note 5991-5934EN, 2015.

- “Performance Characteristics of the Agilent 1290 Infinity II Multicolumn Thermostat”, Technical Overview 5991-5533EN, 2015.

>> Update My Profile | Subscribe to Access Agilent | Article Directory