Access Agilent eNewsletter, February 2015

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Faster, less expensive petrochemical analysis with Agilent ICP-OES

By Neli Drvodelic

Agilent Atomic Spectroscopy Application Engineer

ICP-OES has been used for elemental analysis on a wide range of sample types for more than 20 years. Traditionally, chemists had a choice in ICP-OES between horizontal plasma for sensitivity and vertical plasma to cope with higher concentrations. A newer dual-view hybrid technology (based on a horizontal torch) has attempted to address this selection dilemma, but comes with its own limitations. Conventional dual-view ICP-OES requires multiple readings on the same sample, making it slow and expensive. In addition, the horizontal torch makes it difficult to analyze complex samples with high total dissolved solids.

Synchronous measurement of axial and radial emissions

The new Agilent 5100 Synchronous Vertical Dual-View (SVDV) ICP-OES revolutionizes ICP-OES analysis. It’s faster and uses less gas, without compromising performance on your toughest samples. The 5100 SVDV employs a vertical torch viewed axially for high sensitivity on complex matrix samples and enables synchronous measurement of both axial and radial emissions.

The Agilent 5100 SVDV ICP-OES reduces runtimes by 55%, cuts argon consumption by 50% compared to the conventional dual-view – and delivers the capabilities of four instruments in one:

- SVDV mode easily and synchronously determines elements in axial and radial modes via a fixed optical component.

- In vertical dual-view (VDV) mode, the 5100 sequentially determines elements in the axial and radial modes. The optical component provides sequential measurement of emitted axial light followed by radial light from the torch.

- Dedicated axial measurements

- Dedicated radial measurements

The unique dichroic spectral combiner (DSC) of the Agilent 5100 SVDV ICP-OES has the biggest impact on sample throughput. The DSC measures axial and radial emissions at the same time. Conventional dual-view instruments take a measurement in axial mode, move a mirror, and then measure the same sample again in radial mode. Examples of the versatility and effectiveness of the Agilent 5100 SVDV ICP-OES in petrochemical applications are highlighted in this article.

Precision and no interference with Agilent 5100

Additives for lubricating oils are manufactured for many markets, ranging from adhesives to paints and from cement to conductive coatings. These additives must be monitored for quality purposes, before and after use. We used an Agilent 5100 SVDV ICP-OES to analyze the elemental composition of several additives. Table 1 shows the additives and target elements.

Test sample |

Wt (g) |

Target element |

Preparation |

|---|---|---|---|

Rust inhibitor, anti-wear |

0.0232 |

S, Sb, Zn |

Diluted in 20 mL kerosene |

Corrosion resistant additive, anti-oxidant |

0.0280 |

B, Ca, K, Li |

|

Wax flake powder |

2.0491 |

Cu, Fe, V |

Diluted 90:10 |

Table 1. Parameters of some oil additives submitted for analysis.

Table 2 shows that all the samples met the initial and end criterion of 100 ± 10%.

Wax flake powder

Cu 324.754 nm |

Cu 327.395 nm |

Fe 238.204 nm |

Fe 259.940 nm |

V 309.310 nm |

V 311.837 nm |

|

|---|---|---|---|---|---|---|

|

µg/g |

|||||

Powder A |

1.9 |

2 |

11 |

11 |

0.72 |

0.72 |

Powder B |

1.9 |

2 |

11 |

11 |

0.71 |

0.72 |

Powder C |

2 |

2 |

11 |

11 |

0.75 |

0.75 |

Average |

1.9 |

2 |

11 |

11 |

0.73 |

0.73 |

%RSD |

0.6 |

0.5 |

0.16 |

0.18 |

2.9 |

2.4 |

Expected result |

0 to 50 ppm |

|

0 to 100 ppm |

0 to 50 ppm |

|

|

Rust inhibitor

Sb 206.834 nm |

Sb 217.582 nm |

S 180.669 nm |

S 181.972 nm |

Zn 202.548 nm |

Zn 206.200 nm |

|

|---|---|---|---|---|---|---|

RI_1 |

7.2 |

7.3 |

30 |

30 |

5.7 |

5.7 |

RI_2 |

7.4 |

7.3 |

30 |

30 |

5.7 |

5.7 |

RI_3 |

7.3 |

7.3 |

29 |

30 |

5.7 |

5.7 |

Average |

7.3 |

7.3 |

29 |

30 |

5.7 |

5.7 |

%RSD |

1.1 |

0.3 |

0.34 |

0.05 |

0.16 |

0.15 |

Expected result |

5 to 9% |

|

29 to 32% |

|

5 to 9 % |

|

Corrosion resistant anti-oxidant

B 208.956 nm |

B 249.678 nm |

B 249.772 nm |

Ca 315.887 nm |

Ca 393.366 nm |

Ca 422.673 nm |

K 766.491 nm |

K 769.897 nm |

Li 610.365 nm |

Li 670.783 nm |

|

|---|---|---|---|---|---|---|---|---|---|---|

Anti_1 |

6 |

6 |

6 |

0.11 |

0.12 |

0.11 |

6 |

5 |

4 |

4 |

Anti_2 |

6 |

6 |

6 |

0.11 |

0.12 |

0.11 |

6 |

6 |

4 |

4 |

Anti_3 |

6 |

6 |

6 |

0.11 |

0.12 |

0.11 |

6 |

6 |

4 |

4 |

Average |

6 |

6 |

6 |

0.11 |

0.12 |

0.11 |

6 |

6 |

4 |

4 |

%RSD |

1.5 |

1.5 |

1.5 |

0.5 |

0.38 |

0.56 |

3.3 |

3.4 |

0.7 |

0.6 |

Expected result |

6 to 10% |

|

|

0.05 to 0.15% |

|

6 to 10% |

|

3 to 10% |

|

|

Table 2. Agilent 5100 SVDV ICP-OES spike recoveries for elements in lubricating oil additives (average and precision of three sample readings).

These results show that the Agilent 5100 SVDV ICP-OES is able to achieve excellent precision (from the very low %RSD data) for multiple elements on a variety of different organic sample matrices. The results also show that the Agilent SVDV ICP-OES is able to perform “in method” verification of the concentration of the elements by comparing the results from more than one emission line for each element. The results indicate that there is no interference occurring.

Enlarge

Enlarge

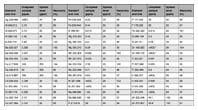

Table 3. Agilent 5100 SVDV ICP-OES spike recoveries for all elements in used engine oil (<MDL = less than method detection limit).

Rapid determination of metals in oils

The determination of metals in oils by ICP-OES using radially-viewed plasma is a well-established technique, especially for laboratories that implement ASTM Standard Test Method D5185-13. The method specifies ICP-OES for the rapid determination of 22 elements in used and unused lubricating oils and base oils.

This time, we used the Agilent 5100 SVDV ICP-OES in the dedicated radial view configuration, which is ideally suited to the analysis of organic samples. Elements were determined in a single run (Table 3). All values were within 10% of the expected values. Analysis time per sample was 30 seconds, which includes a 3-second rinse between samples, as well as three replicate readings. Total argon consumption was only 9.5 L per sample.

Full details of this analysis are available in Agilent publication 5991-5271EN.

Powerful, cost-effective petrochemical analysis

The Agilent 5100 SVDV ICP-OES takes elemental analysis to a new level of performance, particularly in terms of robustness, speed, and reduced costs. With faster sample run times, the 5100 ICP-OES requires less argon gas, leading to significant savings for busy labs. See what the Agilent 5100 ICP-OES can do for you.

Agilent has more than 40 years of collaboration with ASTM International in the creation and management of standardized analysis procedures for the petrochemical industry. Many additional standards have been developed on Agilent instruments including GC, LC, MS, FTIR, and GC/MS. Learn more today about Agilent solutions for the energy and petrochemical industry.

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Table 3.

Element and line |

Unspiked sample (ppm) |

Spiked level (ppm) |

Recovery (%) |

Element and line |

Unspiked sample (ppm) |

Spiked level (ppm) |

Recovery (%) |

Element and line |

Unspiked sample (ppm) |

Spiked level (ppm) |

Recovery (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

Ag 328.068 |

<MDL |

25 |

96 |

Fe 238.204 |

0.45 |

25 |

98 |

P 177.434 |

39 |

50 |

96 |

Al 308.215 |

0.19 |

25 |

93 |

Fe 259.940 |

0.44 |

25 |

96 |

P 178.222 |

39 |

50 |

97 |

Al 309.271 |

0.13 |

25 |

95 |

K 766.491 |

0.019 |

25 |

92 |

Pb 220.353 |

0.015 |

25 |

101 |

Al 396.152 |

0.32 |

25 |

95 |

Mg 279.553 |

0.42 |

25 |

95 |

Si 288.158 |

0.3 |

24 |

95 |

B 249.772 |

5.43 |

25 |

103 |

Mg 280.270 |

0.41 |

25 |

98 |

Si 251.611 |

0.29 |

24 |

95 |

Ba 233.527 |

0.026 |

25 |

105 |

Mg 285.213 |

0.39 |

25 |

95 |

Sn 189.925 |

<MDL* |

26 |

104 |

Ba 493.408 |

0.021 |

25 |

93 |

Mn 293.305 |

0.026 |

25 |

100 |

Sn 242.170 |

<MDL* |

24 |

95 |

Ba 455.403 |

0.023 |

25 |

93 |

Mn 257.610 |

0.025 |

25 |

95 |

Ti 334.941 |

0.001 |

24 |

95 |

Ca 317.933 |

106 |

200 |

104 |

Mo 202.032 |

5.76 |

25 |

100 |

Ti 337.280 |

0.003 |

24 |

95 |

Ca 422.673 |

95 |

200 |

95 |

Mo 203.846 |

5.71 |

25 |

98 |

Ti 350.490 |

0.2 |

24 |

96 |

Ca 315.887 |

106 |

200 |

105 |

Mo 281.615 |

5.64 |

25 |

97 |

V 292.401 |

<MDL |

25 |

98 |

Cd 226.502 |

0.038 |

25 |

102 |

Ni 221.648 |

<MDL |

25 |

102 |

V 309.310 |

0.008 |

24 |

96 |

Cr 205.560 |

0.014 |

25 |

99 |

Ni 231.604 |

<MDL |

25 |

99 |

V 310.229 |

<MDL |

25 |

99 |

Cr 267.716 |

0.033 |

25 |

99 |

Na 588.995 |

1.24 |

25 |

92 |

V 311.070 |

<MDL |

24 |

97 |

Cu 324.754 |

0.13 |

25 |

93 |

Na 589.592 |

1.06 |

25 |

91 |

Zn 202.548 |

46.1 |

100 |

98 |

Cu 327.395 |

0.127 |

25 |

93 |

P 213.618 |

39 |

50 |

99 |

Zn 213.857 |

44.8 |

100 |

97 |

Agilent 5100 SVDV ICP-OES spike recoveries for all elements in used engine oil (<MDL = less than method detection limit).