Access Agilent eNewsletter, October 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Reducing system downtime in energy and chemical applications

By Yun Zou and Hua Wu

Agilent GC Applications

We understand the daily challenges petroleum chemists face with trying to reduce downtime, because time is a precious commodity in your lab. You do not want unnecessary work on your system that disrupts workflows and reduces overall productivity. In this article, we discuss GC solutions using Agilent J&W GC columns – featuring inertness, low bleed, and no particle shedding – designed specifically to reduce downtime.

Use a column with low bleed for sulfur in gas

Agilent J&W DB-Sulfur SCD columns are optimized for use with a sulfur chemiluminescence detector (SCD) to provide low bleed performance and reduced fouling of the detector’s ceramic tubes. The analysis of gaseous sulfur compounds is challenging because they are polar, reactive, and present in widely varying concentrations. SCD is an excellent device for these compounds because its response is inherently linear, equimolar, and far less susceptible to hydrocarbon interferences. However, the SCD requires low bleed GC columns to avoid fouling of the SCD ceramics, and decreasing sensitivity. In addition, volatile sulfur compounds are highly reactive and have absorptive, adsorptive, and metal-catalytic properties. To ensure reliable results, analysis of sulfur compounds requires inert sample pathways.

The DB-Sulfur SCD GC column has low bleed and exceptional inertness. In this example, we analyzed sulfur gas standards on an Agilent 7890B GC configured with an Agilent 355 Sulfur Chemiluminescence Detector with a dual-plasma burner.

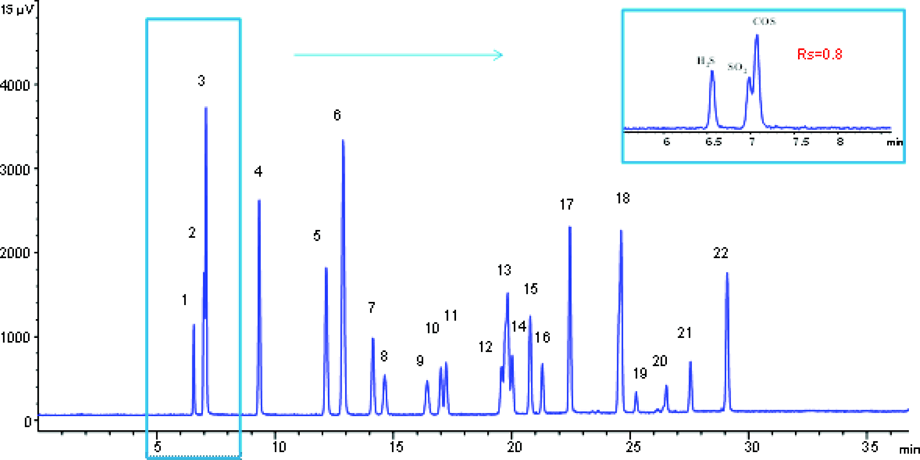

To achieve better resolution of COS and SO2, 1 meter deactivated fused silica tubing was used as a restrictor, connected to a 70 m x 0.53 mm, 4.3 µm DB-Sulfur SCD GC column. Different sulfur gaseous standards applicable to different applications were tested and the analysis began at 35 °C. Compared to a typical initial temperature at 30 °C or below ambient temperature, the GC system was more stable, no cryogenic cooling was required, and the system was suitable for different laboratory conditions.

Enlarge

Enlarge

Figure 1. Chromatogram of sulfur gaseous mix using an Agilent GC/SCD system and Agilent J&W DB-Sulfur SCD column.

Hydrogen sulfide and sulfur dioxide normally co-elute on a regular 60 m x 0.53 mm, 4-µm nonpolar column but they are partially separated on the 70 m DB-Sulfur SCD column with 1 meter deactivated fused silica tubing. This was confirmed by analysis of a gas mix of 22 sulfur compounds (Figure 1). Most of the peaks were well resolved on the column, with excellent peak shapes. Resolution of hydrogen sulfide and sulfur dioxide was about 0.8. 1-Methyl-1-propanethiol, thiophene, and 2-methyl-1-propanethiol are normally difficult to separate because they often show co-elution on commonly used nonpolar (dimethylpolysiloxane) stationary phase columns. Noticeably, Figure 1 reveals improved separation of these three compounds using the DB-Sulfur SCD column.

Use a column with particle traps for petroleum and natural gas

Agilent J&W PLOT PT columns have integral particle traps to stop particles coming out of the column. Operation is more convenient and there is no risk from leaks, as revealed in an analysis of permanent gases and light hydrocarbons. Permanent gases such as H2, O2, Ar, N2, CH4, CO, and CO2 are common target compounds in refinery and natural gases.

Enlarge

Enlarge

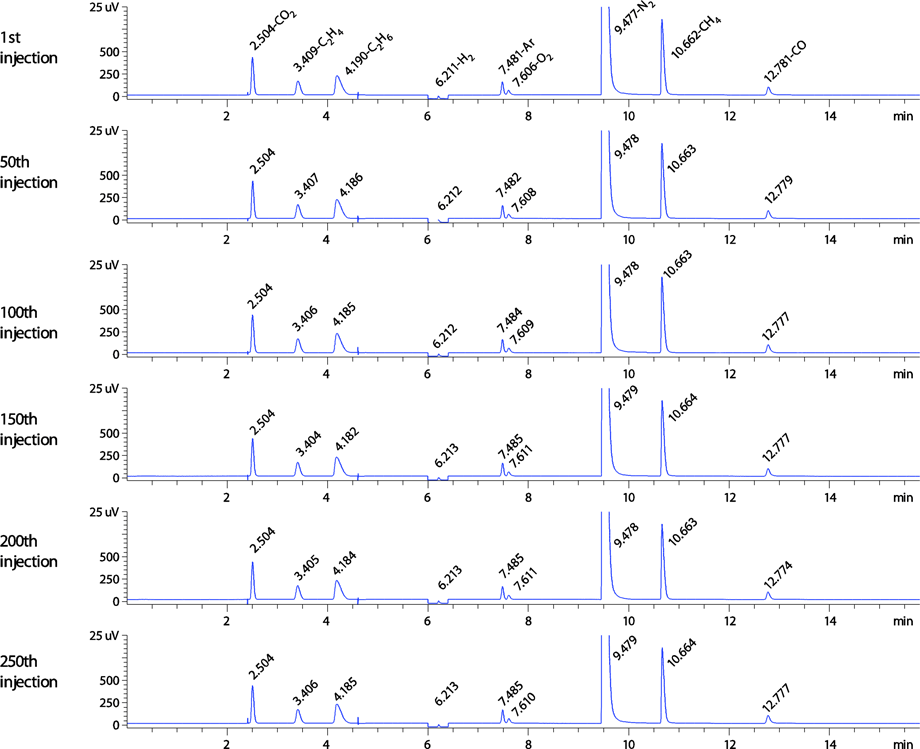

Figure 2. Chromatograms of a standard gas mix resolved using Agilent J&W PLOT PT columns for different injections; carrier gas helium, oven 40 °C (7.8 minutes) to 120 °C at 40 °C/min, 120 °C (5 minutes).

PLOT PT columns deliver good reproducibility of retention times (Figure 2). RSD from 250 replicate analyses of standard gas mix was below 0.06%. This showed that excellent repeatability (intra-day) and long-term precision (inter-day) was achieved using the PLOT PT columns. There were no signal spikes related to particle shedding in the 250 injections of the standard mix gas, indicating that the Agilent J&W PLOT PT columns with integrated dual-ended particle trap technology could prevent particle shedding, protect column switching valves, and offer increased stability and reliability for multicolumn-valve analysis.

Learn how particle trapping technology can help you get consistently reliable analysis. Full details for this example are in Agilent Application Note 5991-4873EN.

Cutting-edge technology cuts your workload

The integrated particle-trapping technology on both ends of Agilent J&W PLOT PT GC columns reduces downtime. In addition, with PLOT PT you can now use GC/MS for detailed, qualitative and quantitative analysis.

Agilent J&W DB-Sulfur SCD columns also provide excellent peak shape and extended detector stability, reducing maintenance and associated downtime, for sulfur chemiluminescence methods that use PDMS stationary phases, such as ASTM D5623 and D5504.

These are just two innovative energy and chemical solutions from Agilent. Take a moment now to explore methods and applications for your specific needs.

>> Update My Profile | Subscribe to Access Agilent | Article Directory