Access Agilent eNewsletter, May 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Use the Agilent MP-AES for challenging geochemical analysis

By Terrance Hettipathirana and Phil Lowenstern

Agilent Spectroscopy Applications

Flame atomic absorption spectrometry (FAAS) has long been the instrument of choice for conducting geochemical analysis. However, when facing current trends for lower detection limits, lower cost of analysis, improved ease-of-use and improved safety, the unique capabilities of the Agilent 4200 MP-AES make it the ideal replacement for FAAS.

The second generation Agilent 4200 MP-AES features an advanced microwave cavity and a torch designed to handle samples with high dissolved solids – offering better detection limits and increased working range over FAAS. The 4200 MP-AES runs on nitrogen, eliminating expensive and hazardous gases such as acetylene. This increases safety and allows unattended operation even in remote locations.

The simplicity of this instrument combined with user-friendly MP Expert software facilitates easy setup and method development with minimal training, even for novice laboratory technicians. Operation in remote field conditions is assured, because the robust system is built for the toughest applications such as engine and lubricating oils and minerals. We discuss a geochemical application here to demonstrate the benefits of the MP-AES in action. You can explore further details in the featured Agilent Application Note 5991-3772EN and in Agilent’s Change is in the air brochure.

Enlarge

Enlarge

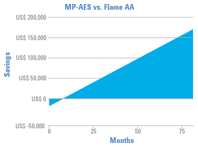

Figure 1. A comparison of running costs and savings of the Agilent 4200 MP-AES versus flame AA. Savings may vary depending on local gas and electricity costs, operator costs, and the number and types of elements.

Operation that’s cheaper and safer

We began our analysis with an estimate of potential cost savings by comparing an FAAS with an air compressor and one year of consumables to a similarly equipped 4200 MP-AES. The study assumed 350 samples per week and five elements per sample. The FAAS was run without an autosampler and all elements were analyzed with air/acetylene. The estimated cost savings to use the MP-AES instead of a FAAS for this analysis was more than $150,000 US dollars over seven years (Figure 1). Replacing your flame AA system with the Agilent 4200 MP-AES can pay for itself within a few months mostly based on cylinder gas savings.

Along with eliminating the need for expensive acetylene or nitrous oxide gases and associated handling and operating costs, the 4200 MP-AES provides additional safety benefits. For example, there is no danger of flammable gas leaks or handling dangers from moving heavy gas cylinders, or freezing regulators in cold climates.

What’s more, mining-specific software applets plus plug-and-play hardware make setup easy, without method development. Ease of use and setup also reduces operating costs by minimizing the need for user training.

Powerful performance at very low detection

The Agilent 4200 MP-AES delivers sensitivity, linear dynamic range, and analysis speed superior to flame AA. With Agilent MP-AES, detection limits down to sub-ppb levels are achievable.

In this trial, we used Dewar nitrogen, although the Agilent 4107 Nitrogen Generator is a better option in remote locations or in metropolitan areas where supply of analytical-grade gases is difficult. A multi-purpose sample introduction system included an inert Agilent OneNeb nebulizer, double pass glass cyclonic spray chamber, orange/green sample pump tubing, and a pump speed of 10 rpm. This setup provided a well-controlled matrix loading to the plasma without sacrificing detection limits. The nebulizer gas flow was mass-flow controlled, providing short and long-term sample nebulization stability during the high total dissolved solid sample analysis. The instrument operated in a fast sequential mode and with the Peltier-cooled CCD detector, background and spectral interferences can be simultaneously corrected automatically, using Agilent MP Expert software.

Table 1 shows the results for two reference materials. Method detection limits were determined by analyzing 10 replicates of acid-digested method blank, with results within ±10% of certified concentrations. The 4200 MP-AES measured silver at low levels by using the ICP-OES inter-element correction technique to correct spectral interferences. Elements such as Cu and Zn showed excellent recoveries across a wide concentration range.

Analyte |

Method detection limit |

Reference material 1 |

Reference material 2 |

||||

|---|---|---|---|---|---|---|---|

MP-AES |

Certified |

Recovery (%) |

MP-AES |

Certified |

Recovery (%) |

||

Ag (mg/kg) |

1 |

45.8 |

48.7 |

94 |

298.7 |

303.7 |

98 |

Cu (wt %) |

0.002 |

0.37 |

0.39 |

95 |

2.30 |

2.37 |

97 |

Ni (wt %) |

0.002 |

0.39 |

0.41 |

97 |

not reported |

||

Pb (wt %) |

0.002 |

1.08 |

1.17 |

93 |

3.24 |

3.30 |

98 |

Zn (wt %) |

0.002 |

0.50 |

0.51 |

98 |

4.24 |

4.27 |

99 |

Table 1. Method detection limits and recoveries for reference materials determined by the Agilent 4200 MP-AES (all results for the solid sample).

Mining Agilent resources for the mining industry

Agilent understands the wide range of needs in the geochemistry, mining, and metals industries. Our instruments and consumables are designed to operate in rugged environments, at high productivity levels and with minimal user training. Whether you are determining major or trace analytes in steel or alloy samples, determining gold, silver and platinum group elements in ore-grade material, analyzing plating solutions, or performing geochemical mapping, Agilent instruments provide the ease-of-use and reliability required to handle the most refined and difficult samples.

Explore Agilent solutions for robust, reliable and efficient geochemical analyses and learn more from the latest Agilent spectroscopy on-demand webinar. Then maximize your productivity and data quality with genuine Atomic and Molecular Spectroscopy Supplies.

>> Update My Profile | Subscribe to Access Agilent | Article Directory