Access Agilent eNewsletter, March 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Fast reliable natural gas analysis in the lab and in the field

By Shannon Coleman and Remko van Loon

Agilent GC Applications

Natural gas is a naturally occurring mixture of gaseous hydrocarbons that consists primarily of methane, but can also include other hydrocarbons (C2-C9 chain length hydrocarbons) and small amounts of impurities (O2, N2, CO2, H2, He, and sulfur-containing compounds).

Before natural gas can be distributed and sold, it must first be certified to meet purity and heat-content standards. The results of this testing is important for two reasons. First, the gas producer needs an accurate reading of the energy content in order to determine the market price for the product. Second, the consumer depends on accurate results to ensure that the product safely delivers the agreed energy content at the contracted price. Agilent natural gas analyzers, based on the Agilent 490 Micro Gas Chromatograph (Micro GC) or the industry-standard Agilent 7890B GC, deliver fast and reliably precise measurements to meet these needs. These ready-to-go analyzers combine the instrument, valve configurations, columns, and software needed to perform standard ASTM or GPA methods used by the industry to determine composition and certify quality.

Laboratory-based Agilent 7890B Natural Gas Analyzers facilitate process monitoring and verification of composition following transport and prior to distribution. The mobile Agilent 490 Micro GC Natural Gas Analyzer provides fast, flexible analysis of natural gas composition in the field, or quick screening during transportation and distribution activities.

Here we explore some examples of the results you can expect from these dedicated instruments, wherever you need to analyze natural gas.

Enlarge

Enlarge

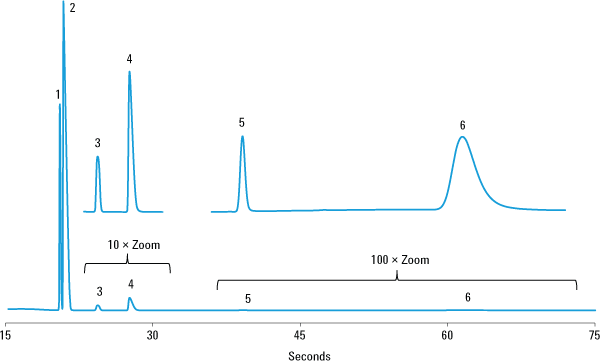

Figure 1. FID channel extended analysis of a natural gas using an Agilent Natural Gas Analyzer.

Enlarge

Enlarge

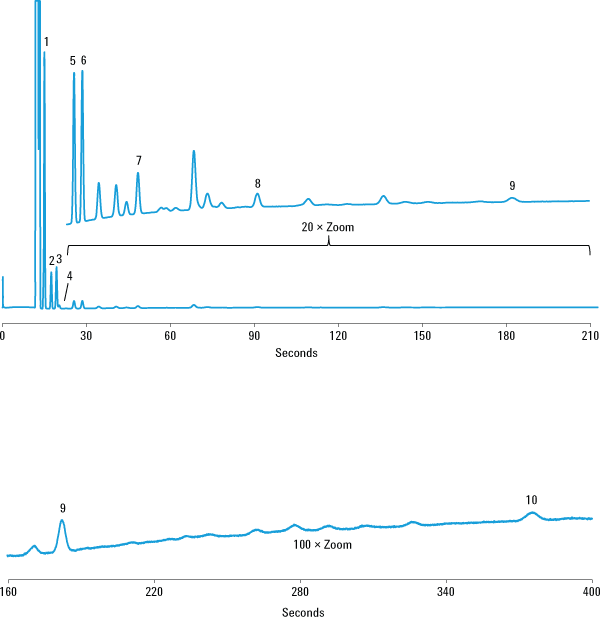

Figure 2. Chromatogram for natural gas on the Agilent J&W PoraPLOT U column channel.

Enlarge

Enlarge

Figure 3. Chromatogram for C3 to C9 hydrocarbons using 6-meter Agilent J&W CP-Sil 5 CB.

Flexible analysis and easy set up in the lab

Using a Capillary Flow Technology Deans Switch configured with a single thermal conductivity detector (TCD) is an effective way to analyze permanent gases in liquefied natural gas (LNG), liquefied petroleum gas (LPG) and gas phase samples. This approach offers a flexible analysis with easy method setup. However, adding a second channel with a flame ionization detector (FID) to the configuration extends hydrocarbon analysis in parallel. This configuration provides entry into a capillary column equivalent to GPA 2186, using an Agilent J&W DB-1 GC column. The advantage of this system is that it allows the analysis of both gas phase and liquid phase samples. It provides better resolution, precision, and sensitivity by using PLOT columns for the permanent gas analysis. In addition, this system is highly configurable. The TCD channel, which allows the separation of all permanent gases, can be extended to analyze through C6 on the Agilent J&W HP-PLOT Q column. Plus, this system configuration allows for the inclusion of an FID channel for the analysis of extended hydrocarbons.

This dual-channel configuration example gave the results shown in Figure 1, demonstrating the full analysis of permanent gases and extended hydrocarbons from an LNG sample. The analysis of a gas phase sample can also be obtained by a second method where the sample is injected through the gas sampling valves instead of the liquid sampling valves.

Fast analysis of natural gas including hydrogen sulfide in the field

The Agilent 490 Micro GC Natural Gas Analyzer is available in four different configurations, depending on the composition of the natural gas and the compounds of interest. In this example, we wanted to analyze hydrogen sulfide in natural gas, and so we used the Agilent 490 Micro GC Natural Gas Analyzer B. This analyzer uses a channel with an Agilent J&W PoraPLOT U column for the separation of methane from the composite air peak (nitrogen and oxygen). The column is also used for the analysis of carbon dioxide, ethane, and propane. Figure 2 shows results of the analysis using the PoraPLOT U column channel for hydrogen sulfide.

A second channel equipped with an Agilent J&W CP-Sil 5 CB analyzes hydrocarbon from propane to n-nonane (Figure 3). When detailed permanent gas analysis is required, a third channel is added to the configuration. This channel equipped with an Agilent J&W CP-MolSieve 5Å column separates and quantifies oxygen and nitrogen.

Agilent has the solutions you need in the lab and in the field

From the well-head to the pipeline, Agilent delivers the natural gas industry solutions you need. Preconfigured and chemically tested, Agilent’s GC and Micro GC Analyzer solutions give you time-saving and cost-effective approaches for rapidly characterizing natural gas composition. Take a moment now to learn more about Agilent’s solutions for the energy and chemicals industry. Then talk to your Agilent representative about how Agilent natural gas analyzers can help you solve your most difficult challenges.

>> Update My Profile | Subscribe to Access Agilent | Article Directory