Access Agilent eNewsletter, August 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Accurate, cost-effective analysis of biodegradable polymers with Agilent GPC solutions

By Stephen Luke

Agilent Product Manager, GPC Columns and Standards

Biodegradation is the degradation of a material by factors such as sunlight and temperature, or the action of enzymes or microbes. In polymer science and engineering, the design of polymers susceptible to biodegradation is of increasing importance for two reasons – polymers that degrade naturally to harmless products in the body may be used in biological devices and in drug delivery, and polymers that break down in the environment are significantly ‘greener’ than traditional plastics.

Biodegradation is key to the suitability of materials for use in drug delivery devices or in temporary structures within the body, such as sutures. For these applications, the ability of the body to naturally break down the material used either as part of the application or post-event is very important, making the removal of the polymer simply a case of allowing the natural process of degradation to occur. Many materials are being investigated for these applications as medical science progresses.

Non-polluting polymers for our "eco-conscious" world

The landfill crisis has made the production of non-polluting polymers for packaging and engineering uses a high priority. These materials need to be able to function, but also break down in the environment once disposed of. When it comes to manufacture, it can be difficult to manage these conflicting requirements. For these materials, the rate of degradation and therefore the lifetime and performance of the polymer in the natural environment is related to the length of the polymer chains in the material, with degradation leading to scission of the polymer chains and a shortening of their length.

Gel permeation chromatography (GPC), also known as size exclusion chromatography (SEC), is a well-known technique for determining the molecular weight distribution of polymers. GPC is essential in the study of biodegradable materials because the technique gives an insight into the rate at which a material might degrade, revealing the presence of degraded polymer chains in a sample.

Agilent has published a range of application data on biodegradable polymers, including application notes on polyhydroxyalkanoate and hyaluronic acid. You will find many more in the Biodegradable Polymers Application Compendium. In this article we discuss results from two specific applications.

Enlarge

Enlarge

Figure 1. Overlaid molecular weight distributions of three lignin samples from GPC using an Agilent PolarGel two-column set.

Enlarge

Enlarge

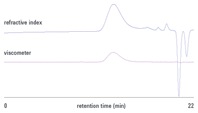

Figure 2. Typical chromatogram from the analysis of a polylactide/poly(lactide-co-glycolide) copolymer showing detector outputs from refractive index and viscometry detectors.

Enlarge

Enlarge

Figure 3. Overlaid Mark-Houwink plots for polylactide (blue) and poly(lactide-co-glycolide) (red) samples.

Lignin, a renewable resource from wood

The analysis of lignin is difficult because of the tendency for the sample to interact with the surface of packing materials used in organic GPC columns. To overcome this, a column packed with a more hydrophilic stationary phase, such as Agilent PolarGel, was used to see if differences in molecular weight could be measured. Samples were made up at 0.2 % (w/v) in DMSO, with 0.1 % LiBr added to reduce sample aggregation, and analyzed without further treatment. Figure 1 shows the overlaid molecular weight distributions, revealing that there are indeed differences between the lignins. Sample C had a broader distribution, which suggested that some degradation may have taken place.

Polylactide and poly(lactide-co-glycolide) – biodegradable for therapeutic devices

It is important to measure the biodegradability of polylactide and poly(lactide-co-glycolide) (PLGA), so that the effectiveness of in vitro products made from PLGA can be improved. Measuring the molecular weight of PLGA by GPC is an important step in understanding this copolymer’s performance. In addition, an assessment of glycolide content in PLGA is needed, as the presence of glycolide results in flexible polymer chains that are able to adopt smaller dimensions compared to polymers with high lactide content.

For PLGA, the relationship between size in solution and molecular weight is not linear but dependent on monomer composition, and so molecular weights from conventional GPC would be distorted. To overcome this, GPC with an advanced viscometer detector is employed. Figure 2 compares the analysis of PLGA using refractive index and viscometer detection, using a two-column set of Agilent PLgel columns to improve resolution.

The Mark-Houwink plot in Figure 3 suggested that there were some structural differences between the homopolymer and the copolymer. This was indicated by the copolymer showing a deviation to lower intrinsic viscosities as a function of molecular weight, indicating it had a smaller, more compact structure.

Agilent offers GPC/SEC solutions for all polymers

GPC/SEC is the only established method for obtaining a comprehensive understanding of a polymer’s molecular weight distribution. Agilent offers an expansive collection of GPC/SEC columns, calibrants, instruments, and resources for high performance separations based on molecular size in solution, with a complete portfolio for the analysis of synthetic and natural polymers, in organic and water-based solvents.

Explore Agilent’s complete range of column, standards, and instruments and see how they offer a clear advantage in the analysis of biodegradable polymers.

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Figure 1.

Overlaid molecular weight distributions of three lignin samples from GPC using an Agilent PolarGel two-column set.