Access Agilent eNewsletter, October 2013

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Agilent Micro GC speeds well gas analysis during hydrocarbon exploration operations

By Remko van Loon

Agilent Application Specialist for Micro GC

During hydrocarbon exploration, sediment and mud are brought to the surface of the borehole by regular drilling operations and analyzed to provide detailed information about the well. Mud logging analysis is used to determine the level of natural gas, requiring the on-site analysis of hydrocarbons (C1 to C5) dissolved in mud within short run times. Determination of natural gas levels is mission critical for making key decisions on additional drilling or the production of the well.

Gas chromatography is an accurate and sensitive technique for separating hydrocarbons and quantifying dissolved natural gas in mud samples. Until now, this application has required a run time of approximately 10 minutes using bench top chromatographs. Agilent’s solution: the compact and portable 490 Micro GC that dramatically reduces the analysis cycle time to just over 30 seconds.

Enlarge

Enlarge

Figure 1. 19" rack mounting for Agilent 490 Micro GC.

Enlarge

Enlarge

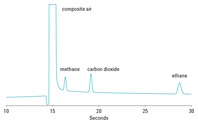

Figure 2. Chromatogram on Agilent PoraPLOT Q (10 meter) channel.

Enlarge

Enlarge

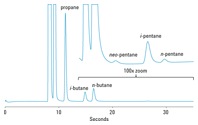

Figure 3. Chromatogram on Agilent PoraPLOT Q (4 meter) channel.

Small, efficient, easy to install

Thanks to miniaturization, the Agilent 490 Micro GC is about the size of a shoe box. Its small size, low power, and gas consumption makes it easy to install in mobile measuring cabinets or explosion proof enclosures. An optional, industry standard Agilent 19 inch rack configuration (shown in Figure 1) further simplifies its integration into mud logging, or hydrocarbon well logging operations.

Two channels and simultaneous analysis provide fast sample characterization

This method was developed on a dual channel Agilent Micro GC. Each channel includes an individually controlled micro-machined injector, narrow-bore analytical column and a micro thermal conductivity detector (µTCD).

Dissolved gases were collected from the drilling fluid samples using a semi permeable membrane prior to analysis by the Agilent 490 Micro GC. The gas sample was injected and measured simultaneously on two analytical channels with a 10 meter and a 4 meter Agilent PoraPLOT Q column. Fast run-to-run times were achieved because the two column channels are operated isothermally, which eliminates the need to cool down the column or stabilize the instrument with each run.

The first 10 meter column channel was operated at a relatively low temperature and provided baseline separation of methane, ethane, and carbon dioxide from the composite air peak in just 30 seconds. A chromatogram and instrument settings are shown in Figure 2.

Figure 3 shows the chromatogram and settings for the second channel. This 4 meter column channel was operated at a high temperature to handle the separation and analysis of the higher hydrocarbons. Propane, butane, and pentane eluted in less than 35 seconds.

Unlike an FID – which needs make-up and burner gases, such as hydrogen and air – the Agilent 490 Micro GC’s thermal conductivity detector uses only the GC carrier gas. As a result, it consumes very little gas, which decreases the cost of ownership.

Results in seconds, when speed matters

The Agilent 490 Micro GC rapidly, reliably, and consistently separates and analyzes hydrocarbons and other gases dissolved in mud samples for use in lithology reports during oil and gas exploration. Isothermal analysis eliminates the need for instrument cool down and stabilization. The 490 Micro GC analyzes sample composition in just over 30 seconds, resulting in close-to-real-time monitoring.

To learn more about the Agilent 490 Micro GC and this mud logging application, download the full Application Note [5991-2699EN].

>> Update My Profile | Subscribe to Access Agilent | Article Directory