Access Agilent eNewsletter, November 2013

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Protect your GC from PLOT column shedding

By Pat Sasso, Ken Lynam, and Laura Provoost

Agilent GC Columns

Porous layer open tubular (PLOT) columns have replaced their packed column counterparts in all aspects of fixed-gas separations [1]. Since their introduction more than 30 years ago, the number of phases has increased and now allows you to achieve all separations in less time and with tremendous efficiency [2]. However, PLOT column technology has had obstacles to overcome related to particle shedding of the various PLOT phases under various column oven conditions. These obstacles give rise to analytical system delays associated with inferior data quality, plugged switching valves, or even damage to rotary valve systems caused by abrasion of critical surfaces. While analysts have employed various remedies to the shedding problem, one type of column offers the convenience of a built-in solution. This article describes Agilent J&W PLOT Particle Trap (PT) columns, which are specially designed to overcome particle shedding.

To overcome shedding problems, many analysts connect particle-trapping devices. These devices can be as simple as a section of capillary column with a polysiloxane phase coating that is thick enough to retain lost particles, or they can be more elaborate glass wool plugs similar to those used to pack GC columns [3].

However, these trapping formats are typically connected to the PLOT column with “press-fit” or low-dead-volume metal connectors. Both types can leak, which requires ongoing maintenance of the connectors. And over time, stationary phase particles can accumulate in the union, which can cause changes in flow restriction.

Agilent was the first manufacturer to introduce integrated particle traps on both ends of the PLOT column. These Agilent J&W PLOT PT columns are ideally suited to retain particles and eliminate sources of leaks – for dramatically improved uptime. You can also trim integrated PT columns as needed for long column life and overall improved ease-of-use.

Enlarge

Enlarge

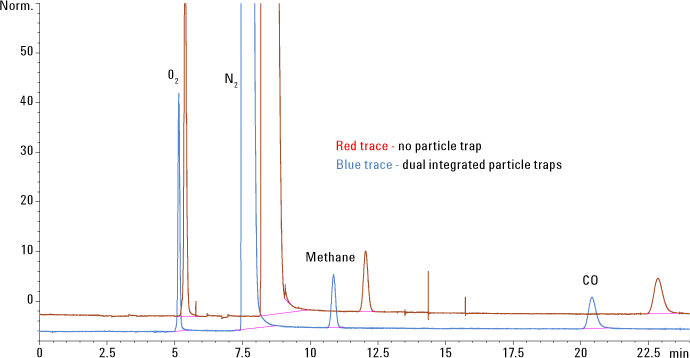

Figure 1. Mixture of fixed gases on Agilent J&W CP-Molsieve 5Å column shows spikes when particle traps are removed (red trace) and no spikes with dual-ended integrated traps (blue trace).

Enlarge

Enlarge

Figure 2. C1 to C4 hydrocarbon mix shows no spikes on Agilent J&W HP-PLOT Al2O3 KCl PT column with integrated dual-ended particle traps.

Clean, stable baselines with PLOT columns

Figure 1 and 2 show how the integrated dual-ended particle trap technology completely removes particle shedding. This technology gives you greater reliability, especially for multicolumn installations that use valves for the backflush or heart cutting techniques that provide optimized separations of complex mixtures.

Figure 1 shows an overlay of two fixed-gas separations – one with dual integrated particle traps and one with the traps removed. These analyses used an Agilent J&W CP-Molsieve 5Å, 25 m × 0.53 mm column and a thermal conductivity detector (TCD). You can clearly see that the integrated particle traps prevent troublesome spikes.

Figure 2 demonstrates that the Agilent J&W HP-PLOT Al2O3 KCl PT GC column analyzes hydrocarbons without shedding particles. This analysis used a flame ionization detector (FID) and a 50 m × 0.53 mm column with a 15 µm film.

Optimize your analyses with a wide range of PLOT column phases

The integrated particle trapping technology on both ends of Agilent J&W PLOT PT GC columns reduces downtime, while allowing you to use GC/MS for detailed qualitative and quantitative analyses. Agilent J&W PLOT PT GC columns are the only PLOT columns that are stabilized with integrated particle trapping technology on both ends. They are ideal for analyses of light gases, solvents, and other volatile organic compounds in hydrocarbon processing, environmental (air), forensic, and food applications.

Agilent continues to expand its range of particle trap columns, with recent additions in porous polymer, alumina oxide, and MolSieve PLOT. These additions include:

- CP-Al2O3/KCl PT and CP-Al2O3/Na2SO4 PT

- GS-Alumina PT and GS-Alumina KCl PT

- HP-PLOT Al2O3 S PT and HP-PLOT Al2O3 M PT

- CP-Molsieve 5Å PT

Agilent has a wide range of column configurations, but you can also order a custom column configuration for your specific needs from the Agilent J&W GC Custom Column Shop.

Take a moment now to see how Agilent J&W PLOT PT columns can improve your gas separations, and read the latest application notes that reveal the benefits of particle trapping technology for fixed gases and C4 hydrocarbons.

References

- V. Giarrocco, R. Firor. “Trace Level Hydrocarbon Impurities in Ethylene and Propylene.” 5965-7824E (2000).

- Z. Ji. “GC/TCD Analysis of a Natural Gas Sample on a Single HP-PLOT Q Column.” 5966-0978E (2000).

- Z. Ji, I. Chang, A. Broske. Optimized Determination of C1-C6 Impurities in Propylene and Ethylene using HP-PLOT/Al2O3 Columns. 5962-8417E (2000).

>> Update My Profile | Subscribe to Access Agilent | Article Directory