Revident LC/Q-TOF

The Agilent Revident LC/Q-TOF is ideal for small molecule applications in food safety and environmental analysis, as well as metabolomics, pharmaceutical, and forensic analyses. It supports environmentally friendly initiatives through a combination of intelligent instrument design and sustainable manufacturing practices:

- Modular architecture minimizes waste by enabling targeted component replacement rather than full system overhauls

- Intelligent diagnostics help pinpoint and specifically identify components requiring maintenance

- Data-driven automation with intelligent reflex saves time and energy

- Steady energy use by eliminating the need to vent with VacShield

- Early maintenance feedback dashboard minimizes unplanned downtime, saving time and energy

- Optional oil-free pump minimizes oil waste and energy consumption

- Sustainable recycled product and packaging content

- End-of-life take-back incentives to ensure proper recycling

Additional Information

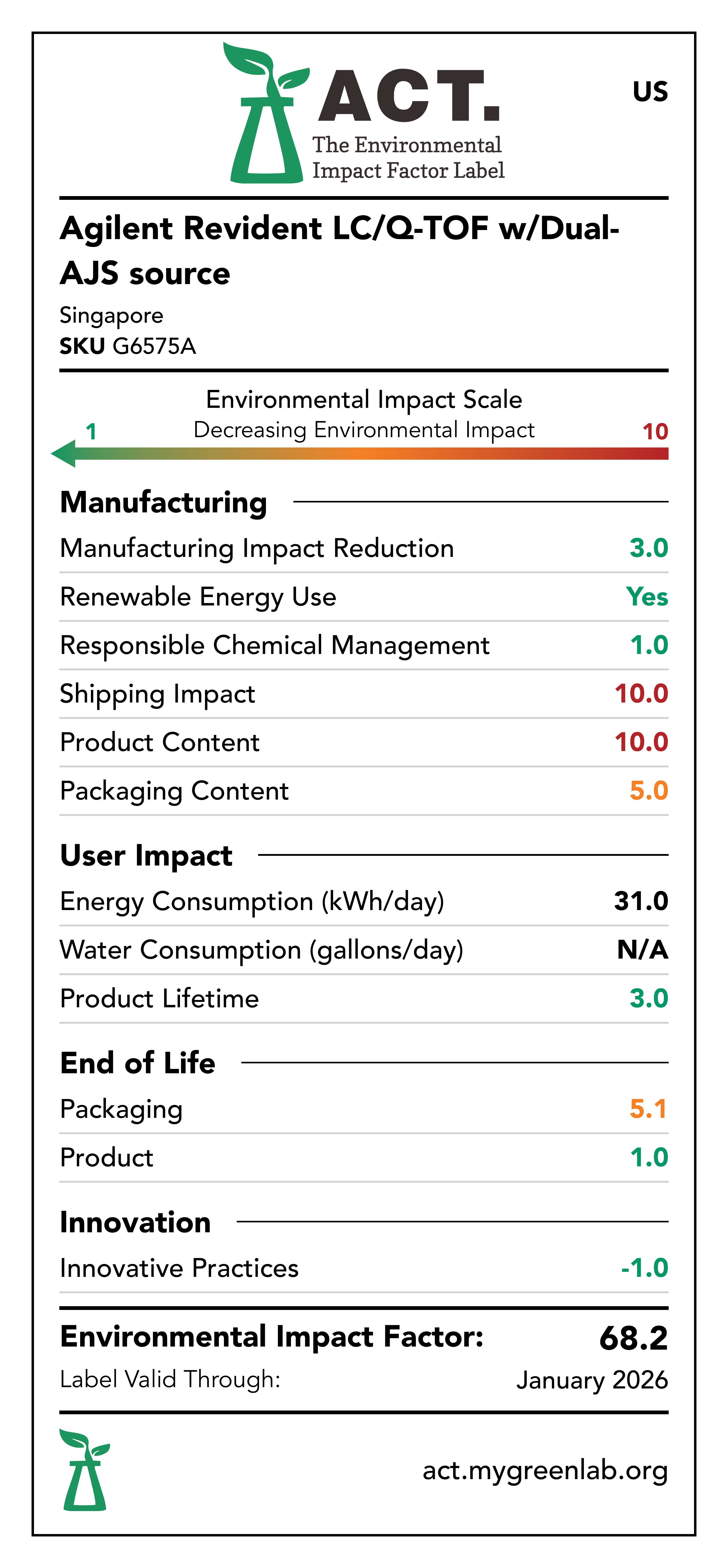

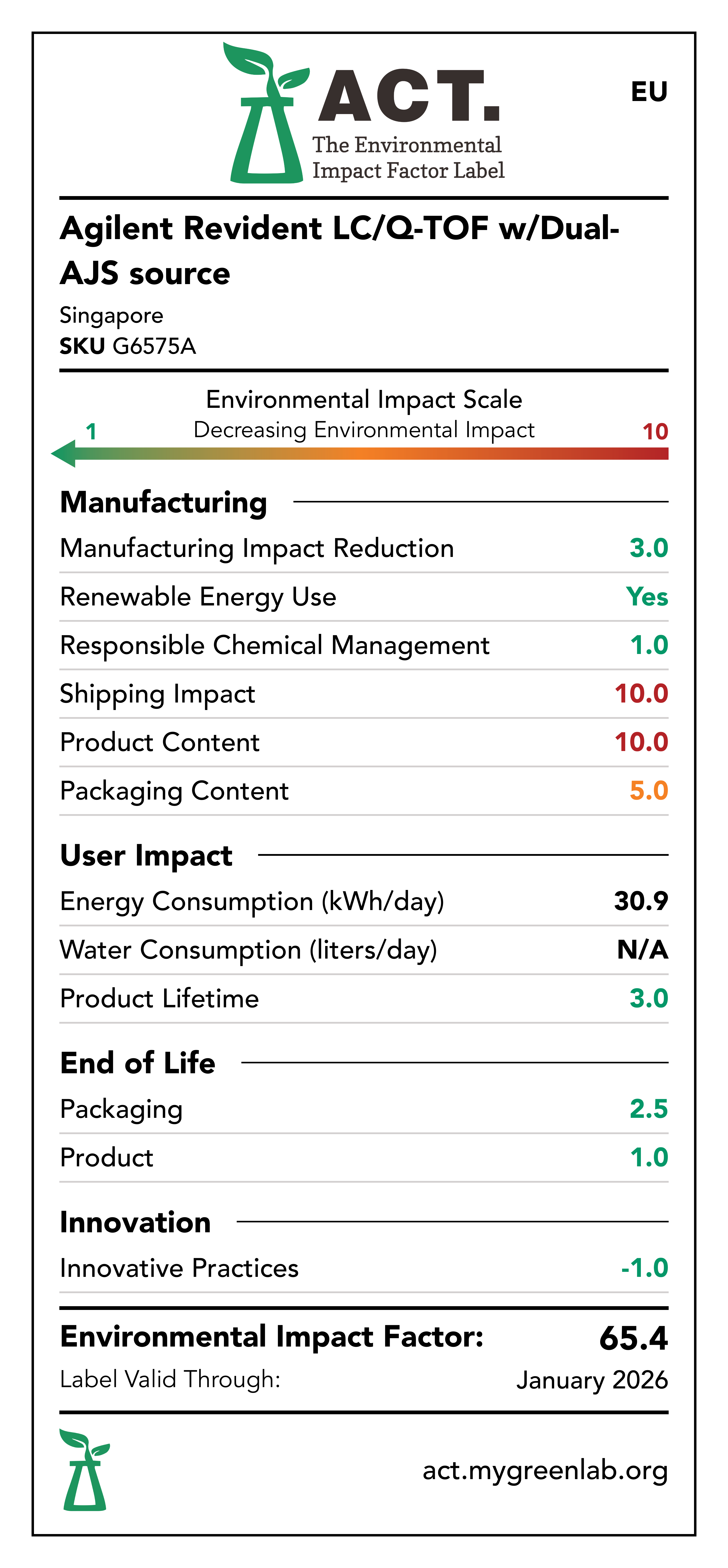

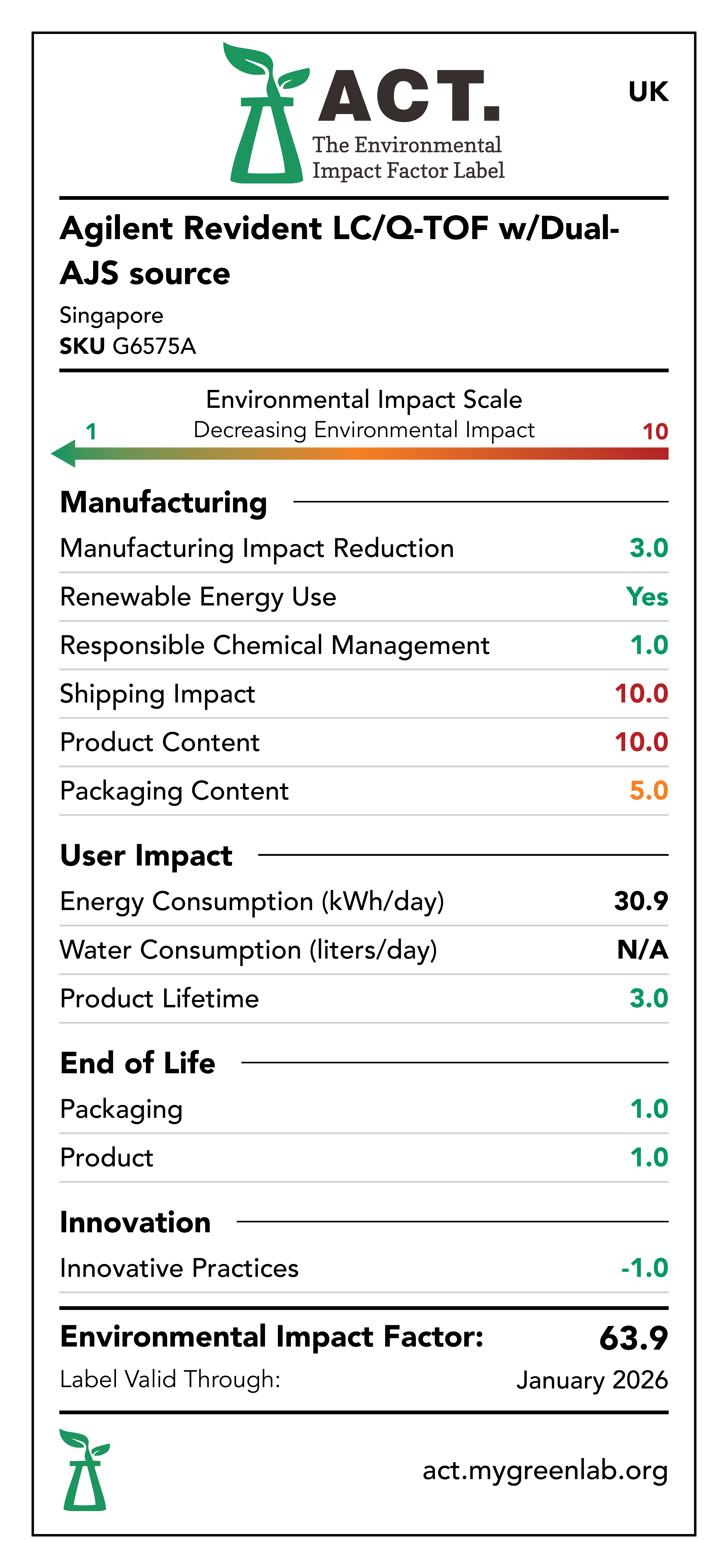

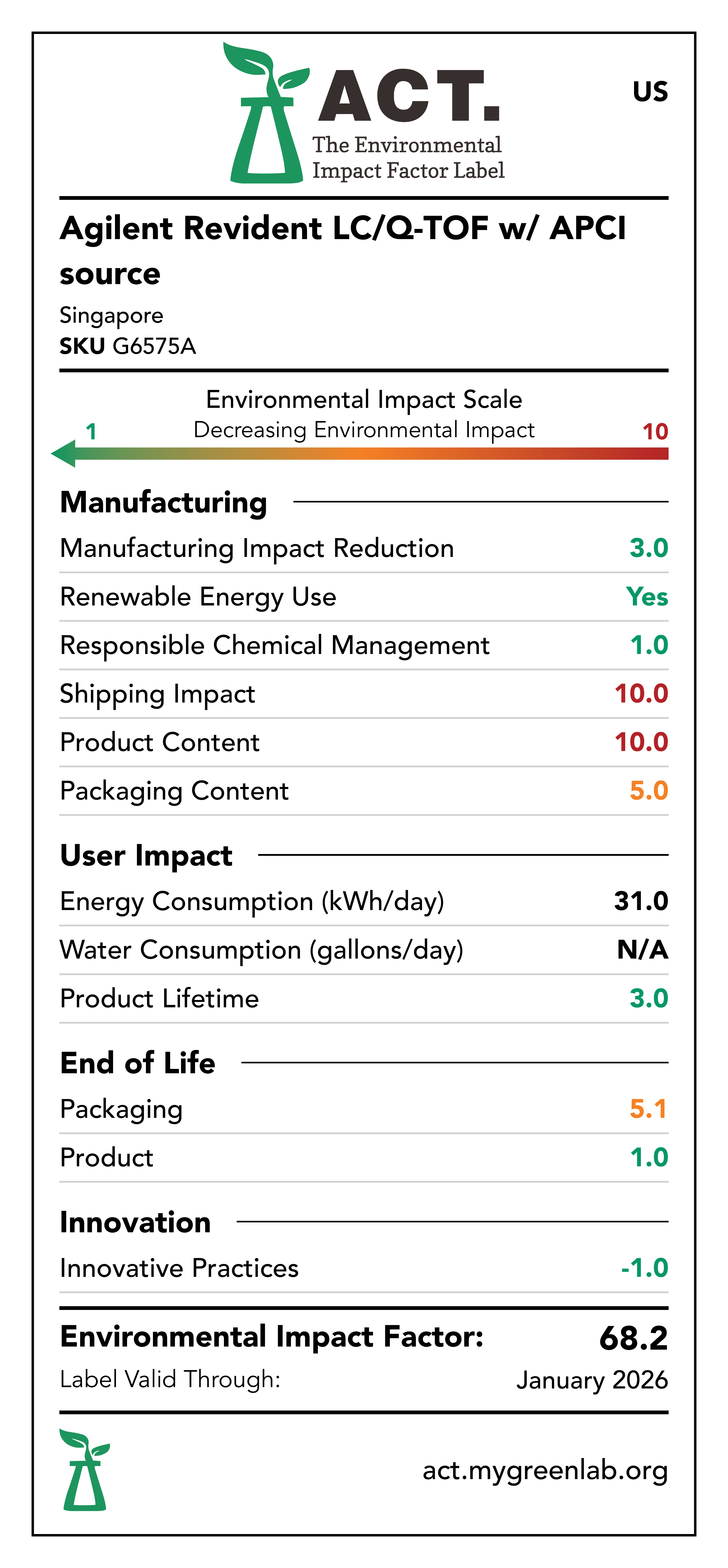

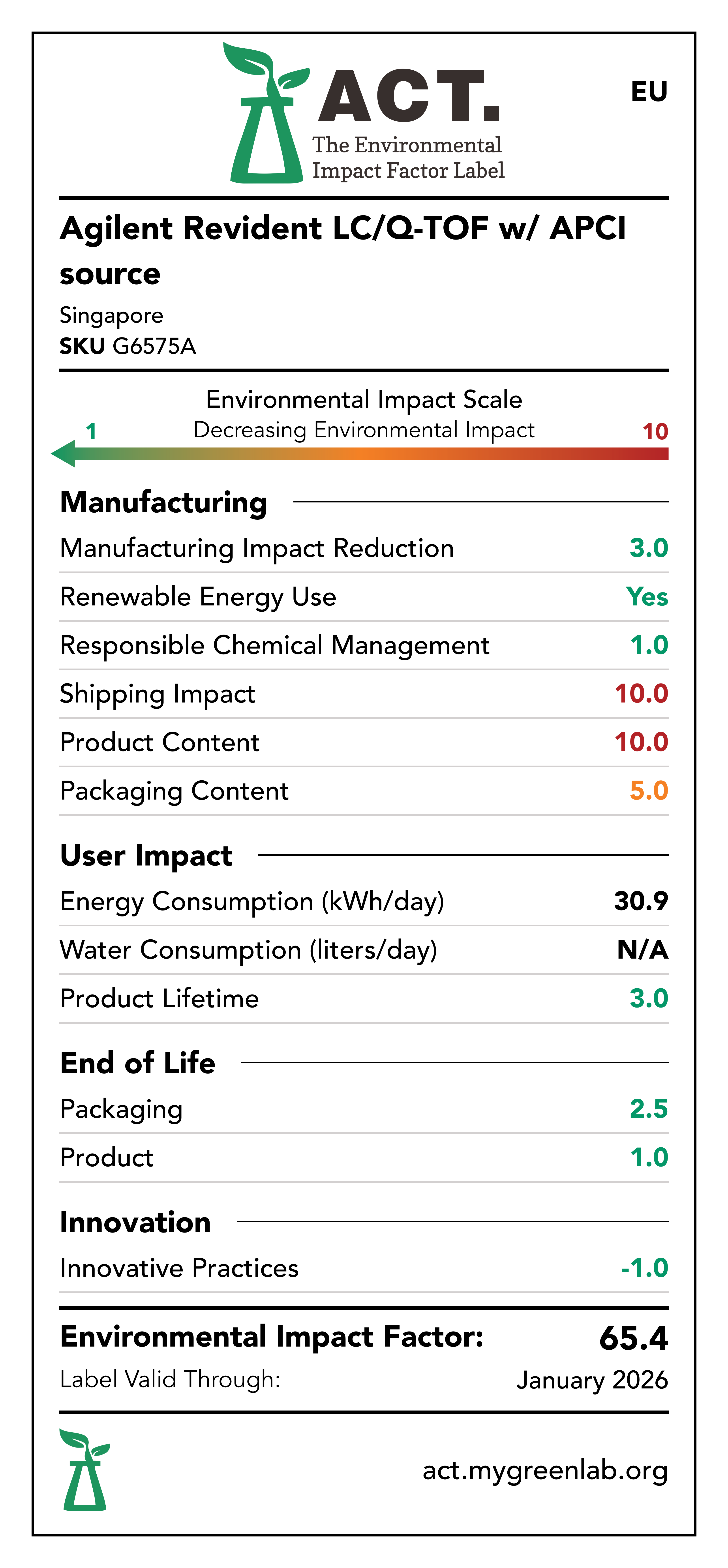

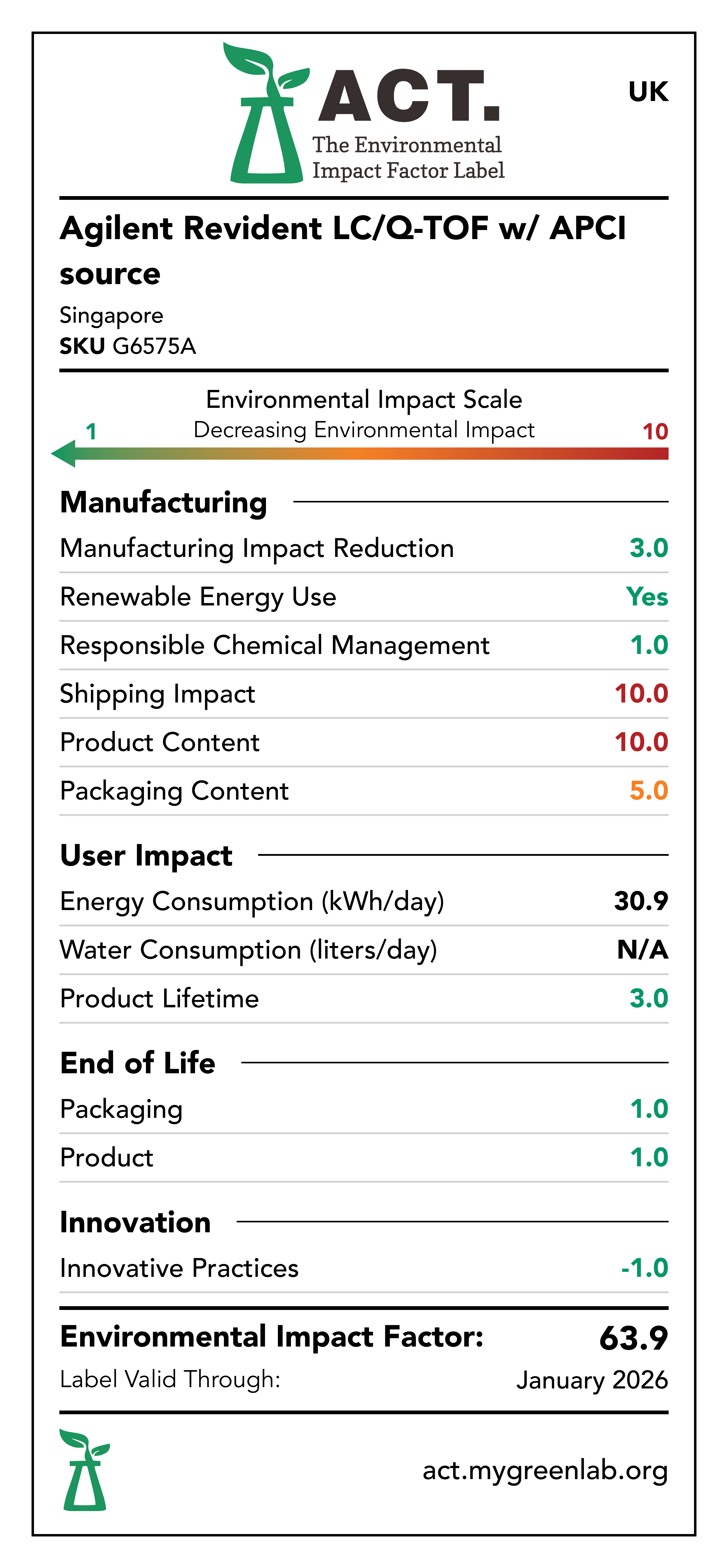

Manufacturing Impact Reduction

The Singapore facility that manufactures the Agilent Revident LC/Q-TOF systems has implemented measures within the past five years to reduce its energy and water usage. These initiatives include an LED lighting retrofit which is estimated to save over 775 MWh and installation of low-flow fixtures.

Renewable Energy Use

The Singapore facility that manufactures the Agilent Revident LC/Q-TOF systems utilizes onsite renewable energy in the form of solar photovoltaics.

Responsible Chemical Management

The Singapore facility that manufactures the Agilent Revident LC/Q-TOF systems has implemented a robust EHS program which includes ISO 14001 certification. Additionally, the Agilent Revident LC/Q-TOF systems are EU RoHS 2011/65/EU compliant and do not utilize any chemicals of concern.

Shipping Impact

The Agilent Revident LC/Q-TOF systems are manufactured in Singapore and are distributed to the US market via Memphis, Tennessee; and to the EU and UK markets via Waghäusel, Germany.

Product Content

The Agilent Revident LC/Q-TOF systems do not currently contain any sustainable content.

Packaging Content

The Agilent Revident LC/Q-TOF systems are packaged using cardboard, polyethylene bag, steel brackets, and aluminum straps. The cardboard components contain approximately 55% recycled material, resulting in almost 20% recycled content in the Agilent Revident LC/Q-TOF packaging system.

Energy Consumption

Typical daily energy usage for the Agilent Revident LC/Q-TOF systems is based on 8 hours of operation and 16 hours of standby. It also includes the energy draw from the system's external pump.

Water Consumption

The Agilent Revident LC/Q-TOF systems do not require water during their use phase.

Lifetime Rating

The Agilent Revident LC/Q-TOF systems are guaranteed 10 years of typical use under the Agilent Value Promise. Additionally, the products have guaranteed support for a minimum of 7 years after discontinuation. Lastly, based on the lifetime of previous, comparable product iterations, the Agilent Revident LC/Q-TOF systems are likely to exceed 15 years of service under typical use.

Packaging End-of-Life

The Agilent Revident LC/Q-TOF packaging system includes cardboard, plastic foam and bag, and various metal components. In the US, the cardboard and metal components are readily recyclable while the plastic components are either landfilled or incinerated. In the UK, and select EU counties, Agilent participates in Extended Producer Responsibility (EPR) schemes to support the responsible management of packaging at its end-of-life. In the remaining EU countries, the cardboard and metal components are readily recyclable while the plastic materials are either recycled, landfilled, or incinerated depending on the available infrastructure.

Product End-of-Life

The Agilent Revident LC/Q-TOF systems are eligible for take-back programs in the US, EU, and UK Markets.

Innovative Practices

The Agilent Revident LC/Q-TOF systems are the first in the family of intelligent QTOF "self-aware" instruments. The systems contain approximately 2,500 onboard telemetry registers that are continuously polled and monitored. These instruments were purposefully designed as "modular for serviceability". The modular approach obsoletes needless replacement practices; often perfectly functional components are replaced/discarded which this modularity helps avoid. This results in less waste for the end user.

Supporting resources

DE-006461