1290 Infinity II LC System

The 1290 Infinity II LC is an ultrahigh performance liquid chromatography instrument (UHPLC) that has market-leading sample capacity and is designed for the lowest dispersion for the most challenging UHPLC experiments. The 1290 embodies the next generation of UHPLC, with the exceptional reliability and robustness you expect from Agilent, plus breakthrough UHPLC technologies to achieve unmatched separation and detection performance.

The 1290 Infinity II LC offers:

- Highest energy efficiency per sample in the InfinityLab LC portfolio

- Minimized solvent consumption and waste

- Low failures due to matching InfinityLab supplies

- End-of-life tack-back incentives to ensure proper recycling

Additional Information

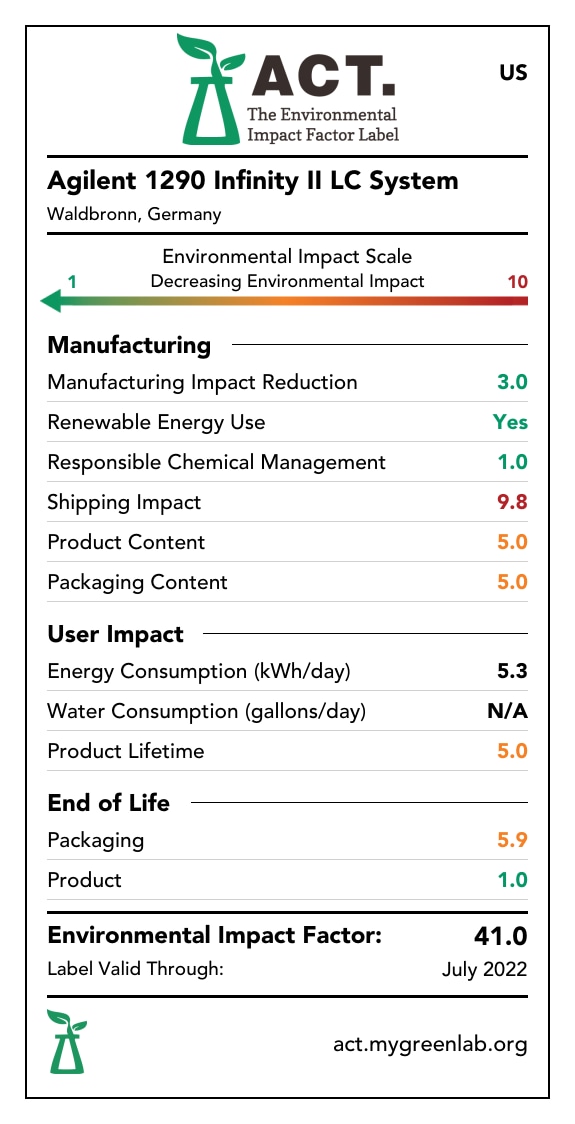

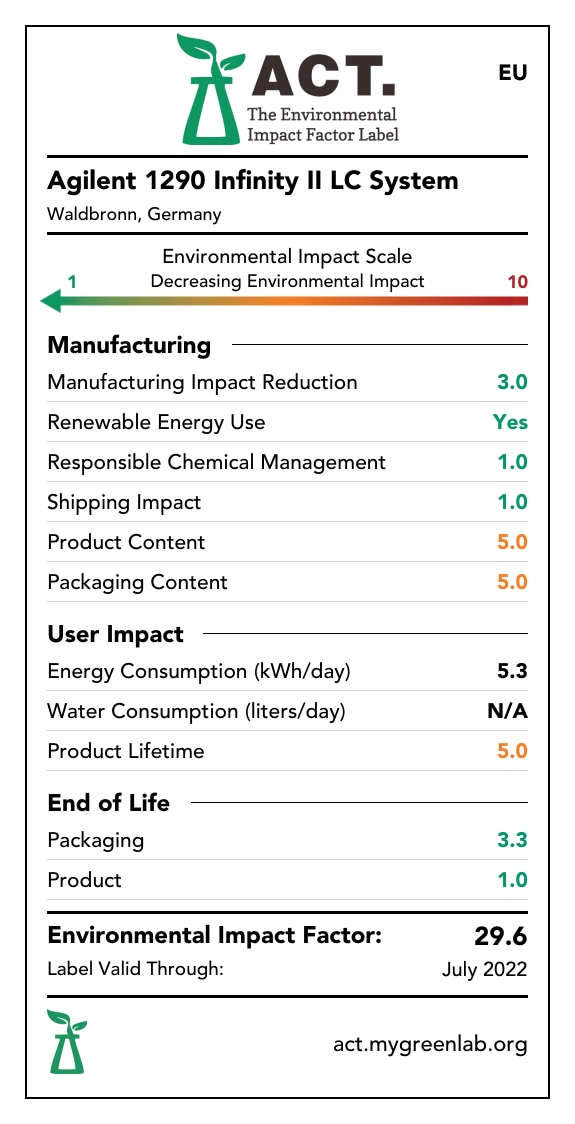

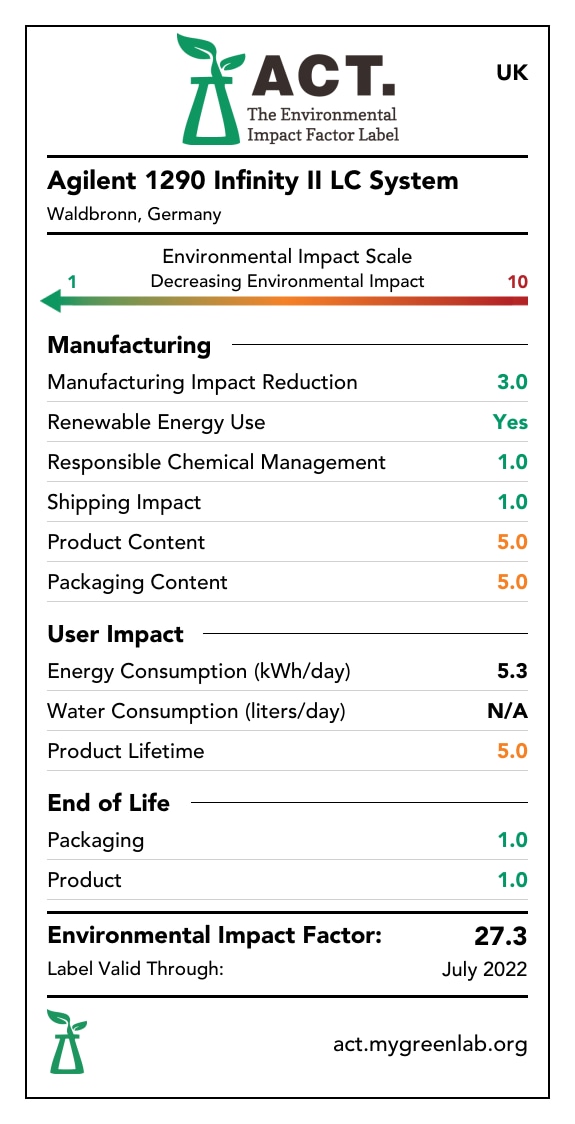

Manufacturing Impact Reduction

This category evaluates the steps that have been taken to reduce energy, water, and waste at their manufacturing facility. Agilent has implemented various initiatives at the facility where the 1290 Infinity II LC System is manufactured in order to reduce the facility's energy and water consumption. These initiatives, which include rain water harvesting, equipment replacement, and an upgraded, on-site combined heat and power plant, have resulted in energy and water reductions relative to a 2015 baseline.

Renewable Energy Use

Agilent has a large photovoltaic system to support and offset electricity from the grid to help produce its products. The average capacity of the system is approximately 250 kWh per year.

Responsible Chemical Management

Agilent has implemented policies and procedures internally and with its supply chain, following the General Specification for the Environment (GSE), to understand and communicate hazardous chemistries. Further, Agilent's manufacturing facility is ISO 14001 certified and the 1290 Infinity II LC System is EU RoHS compliant.

Shipping Impact

Agilent's 1290 Infinity II LC System is manufactured in Waldbronn, Germany. Agilent services the US market through its distribution center in Memphis, TN.

Product Content

Agilent dematerialized the 1260 Infinity II Thermostat (which is used in the 1290 Infinity II LC System) and 1290 Infinity II Multi-Column Compartment. These reductions are relative to the modular components' Infinity I predecessors; the 1260 Infinity II Thermostat reduction is compared to G1330B and 1290 Infinity II Multi-Column Compartment is compared to G1316C.

Packaging Content

The corrugated board packaging material for the Agilent 1290 Infinity II System contains over 40% of recycled fiber.

Energy Consumption

The Agilent 1290 Infinity II LC System consumes approximately 5.3 kWh per day. The system was tested using the system following parameters:

- Sample: readily commercially available sample (e.g. RRLC mix)

- Column: 2.1 x 50 mm, 1.8 µm

- Mobile phases: water and methanol

- Gradient: 30% at 0 minute, 95% at 2 minutes, 95% at 3 minutes

- Stop time: 3 minutes

- Post time: 1 minutes

- Flow rate: 0.8 mL/min (avg. pressure 550 bar 400/700)

- Injection volume: 1.25 µL

- Sample thermostat: 4 Grad.

- Column temperature: 40 Grad.

- UV detector: 254 nm / 4 (ref. 360 nm / 100)

- Peak width: > 0.0063 minute (.13 second response time; 40 Hz)

Water Consumption

This product does not consume water when it is in use.

Lifetime Rating

The Agilent Value Promise guarantees that the Agilent 1290 Infinity II LC System will last at least 10 years.

Packaging End-of-Life

The 1290 Infinity II LC System packaging materials includes cardboard, polyethylene, and polypropylene. In the US, the cardboard is readily recyclable; however, the infrastructure and market for recycling polypropylene and polyethylene is not readily available.

Product End-of-Life

Agilent offers an active take-back / refurbishment program for the 1290 Infinity II LC System in EU and US.