Access Agilent eNewsletter, March 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Robust, leak-free connections from Agilent reduce GC costs, downtime, and rework

By Ken Lynam

Agilent GC R&D/Applications Chemist

One of the main causes of high background noise and poor Gas Chromatography (GC) are leaking column connections. Leaks and the need for retightening connections have been huge issues in GC since its inception. For environmental labs that work with heavy matrixes and trace analysis, leaks can lead to high column consumption, causing increased cost per analysis and more downtime.

Making column connections is one of the most routine of lab tasks, but it must be done with care to ensure a robust, leak-free connection. In addition, the design of the connector can make a big difference in the effectiveness of the connection, and hence the overall integrity of the GC flow path.

Agilent has introduced a new stainless-steel Self Tightening Column Nut that provides leak-free connections without the need for wrenches or adaptors. The new nut delivers reliable column connections that don’t need to be retightened in use and provides better baselines, peak integration, and less rework. The upside is improved system performance and productivity, resulting in the ability to analyze more samples with unattended operation.

Piston-powered self tightening

The new Agilent Self Tightening Column Nut contains a spring-driven piston that continuously presses on the ferrule to maintain a leak-free seal even after thermal cycling, with no leaks after 100 hours at 350 °C. This eliminates the need for retightening during sample sequence. The finger-tight design makes it easy to achieve a leak-free seal without the need for tools that can damage fittings, resulting in expensive repair. In addition, the low-torque seal means that ferrules are easy to remove – they don’t crumble or stick, making maintenance faster and easier.

Enlarge

Enlarge

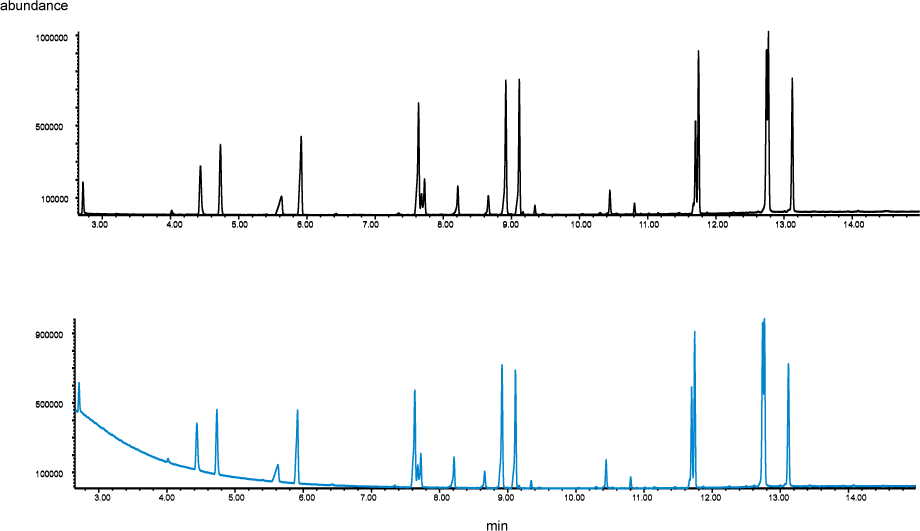

Figure 1. Total ion chromatograms of a semi-volatile short mix immediately after ferrule retightening (above) and after 25 subsequent injections using standard fittings (below) with 85/15 polyimide/graphite ferrules.

These self tightening nuts offer a major improvement in terms of ease-of-use by permanently eliminating the need to retighten polyimide/graphite ferrules. In extensive trials, nuts using 85/15 polyimide/graphite ferrules delivered a gas-tight seal, with heat cycling between 32 ºC and 320 ºC, over 300-plus injections without user intervention to retighten the fitting at either the inlet or transfer line. In contrast, standard fittings with the same type of polyimide/graphite ferrules leaked and required retightening at the transfer line after just a few heat cycles, as you can see in Figure 1.

Another key feature of the Agilent Self Tightening Column Nuts is that polyimide/graphite ferrules do not stick inside them. Columns can be easily changed and the fittings reused without the need to dig old ferrules out of the transfer-line nut. Full details of this analysis are given in Agilent Application Note Proof of Long-Term, Leak-Free Performance for a Novel Self-tightening GC Column Nut.

Imagination leads to innovation

Small things can deliver big improvements. The Agilent Self Tightening Column Nut is a simple but imaginative solution to an age-old concern in gas chromatography. The nut requires very low investment, no risk, and is truly novel ― there is nothing like it. This is just the first part of our story on Making Better GC Connections, so look out for another chapter on better connections in next month’s Access Agilent. In the meantime, additional information on Agilent Inert Flow Path solutions and Agilent J&W Ultra Inert GC columns is just a click away.

>> Update My Profile | Subscribe to Access Agilent | Article Directory