Access Agilent eNewsletter, September 2013

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Agilent 490-PRO Micro GC delivers rapid, consistent analyses of propane and butane product gas streams

By Serge Syz

QC LAB Inc., Calgary, Canada

and Remko van Loon

Agilent Application Specialist for Micro GC

Rugged stand-alone instruments that quickly deliver consistent results are essential for process monitoring and control. The Agilent 490-PRO Micro GC is well suited to this task, as demonstrated by five years of analyses of liquefied propane and butane at a gas-processing site.

Liquefied propane and butane stream (liquefied petroleum gas, LPG) are mixtures of hydrocarbons used as a fuel for vehicles and heating systems, and as more environmentally friendly replacements for chlorofluorohydrocarbons in aerosol propellant and refrigerant gases. LPGs consist mainly of propane and butane, but other hydrocarbons such as ethane and pentane are usually present in low concentrations.

QC LAB Inc. has been demonstrating the effectiveness of the Agilent Micro GC instrumentation to the gas processing industry in Canada for more than 20 years. A process micro gas chromatograph from Agilent was installed at a facility that produced propane and butane products. The installation enabled improved product pricing by delivery of specified propane and butane products, as opposed to a liquefied petroleum product that contained a mixture of both gases.

Miniature GC delivers analyses in one minute

The Agilent 490 Micro GC performs fast and accurate analyses of a wide range of gas samples, and can hold up to four independently controlled chromatographic channels. Each channel is a complete miniaturized gas chromatograph and includes a microelectromechanical-based (MEMS) injector, a thermal conductivity detector, and narrow-bore analytical columns.

Additionally, the instrument portfolio includes a process GC – the Agilent 490-PRO Micro GC. This instrument features on-board data collection, peak integration, result calculation, and report generation. The 490-PRO Micro GC does not require a connection with a chromatography data system to generate data and results. To program the method parameters on the 490-PRO Micro GC, you use the powerful Agilent PROstation set-up tool. During day-to-day use, the PROstation is disconnected and user defined analysis results and information are transferred to an external system in an unattended manner using an industry-standard protocol, such as 4-20mA or ModBus.

Enlarge

Enlarge

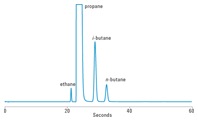

Figure 1. Chromatogram for the propane product clearly shows analysis in less than one minute, for near-real-time process control.

Enlarge

Enlarge

Figure 2. Chromatogram for the butane product on the same column channel demonstrates rapid results that enable instant process optimization.

QC LAB set up the 490-PRO Micro GC to provide propane and butane analyses in 60 seconds, with results directly delivered to the plant process control systems. The GC system is equipped with a single analytical channel that contains an 8-m CP-Sil 5 CB column. This single-column setup provides baseline separation for all components of interest, while using a minimum of helium carrier gas. One bottle of helium lasts for more than three years because the system uses just a few milliliters per minute.

The on-line chromatograph is equipped with an automatic multiple stream selection system that allows personnel to choose among the two product streams and a calibration gas standard. This sample introduction setup enables intermittent analyses of the propane and butane product streams and makes it possible to perform periodic, automated verifications or calibrations.

Single method for two sample streams

We used the same column channel, instrument settings, and peak integration settings to analyze both propane and butane sample streams. Figure 1 shows a chromatogram for the propane product. This stream mainly consists of propane, with some ethane, i-butane, and n-butane. The butane stream consists of mostly i-butane and n-butane, with low levels of the other C2-C5 saturated hydrocarbons (Figure 2).

A 60-second on-line analysis enables near real-time transfer of product composition to the plant process control system for faster trend analysis and instant process optimization. Agilent publication 5991-1972EN shows examples of trend plotting. Rapid notification of out-of-specification products allows you (Agilent will not adjust these processes) to quickly adjust plant processes to return to specifications.

Precise and reliable results, day after day

The Agilent 490-PRO Micro GC was installed in 2007 and very stable results have been observed. Table 1 shows the calculated values for the calibration verification obtained in 2009 and 2012 using the calibration curves analyzed during installation in 2007. These results show only minimal deviation from the initial calibrated values, which demonstrates the stable long-term performance of the MEMS-based technology.

Calibration |

Verification |

Verification |

Precision |

|

|---|---|---|---|---|

Methane |

0.985 |

0.977 |

1.011 |

0.00051 |

Ethane |

4.800 |

4.806 |

4.833 |

0.00028 |

Propane |

89.780 |

89.794 |

89.806 |

0.00153 |

i-Butane |

2.140 |

2.131 |

2.129 |

0.00088 |

n-Butane |

1.260 |

1.270 |

1.241 |

0.00135 |

i-Pentane |

0.521 |

0.516 |

0.498 |

0.00005 |

n-Pentane |

0.514 |

0.507 |

0.483 |

0.00006 |

Table 1. Method performance shows stable results.

Exceptionally good precision is still observed after five years of 24/7 operation. In that period, no maintenance was required and more than a million (1,160,710) samples were analyzed.

Lab-quality analyses for on-line/at-line applications

These results clearly show that the Agilent 490-PRO Micro GC, equipped with an 8-m CP-Sil 5 CB column, is capable of rapid, one-minute analysis of propane and butane streams in a process environment. The short analysis time enables more accurate trend display, better-informed decision-making, and faster process control. The single channel setup and low carrier gas consumption of the 490-PRO Micro GC keeps operating costs to a minimum and a lasting return on your investment.

With the 490-PRO Micro GC, Agilent brings a lab quality analyses to on-line/at-line applications. To learn more about the Agilent 490-PRO Micro GC and this analysis, download the full Application Note 5991-1972EN.

>> Update My Profile | Subscribe to Access Agilent | Article Directory