Access Agilent eNewsletter, November 2013

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Agilent preventive maintenance kits supply everything you need to maintain LC performance

By Katja Kornetzky

Agilent Product Manager, LC Supplies

In a busy lab, it can be hard to spot a gradual decline in the performance of your LC system. The system may have operated well over the past year, but perhaps the baseline is noisier now… or columns don’t last quite as long… or sensitivity seems to have declined… or retention times are more variable than they used to be. Any or all of these issues can be caused by a lack of preventive maintenance, and so it’s critically important to set up a regular maintenance program for your system and keep supplies in stock to replace worn or damaged components on a regular basis.

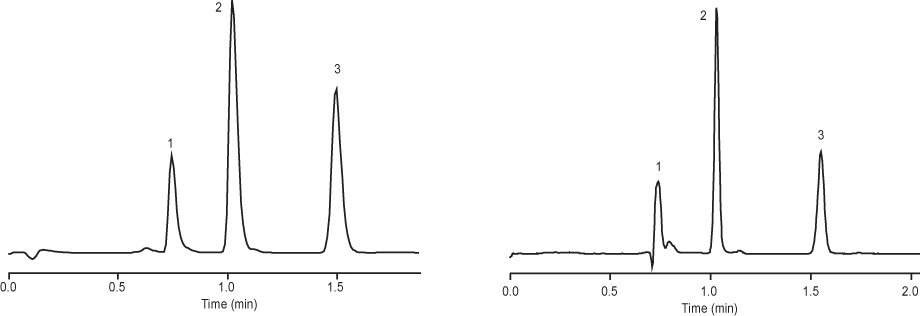

Maintaining your instruments and replacing crucial parts at consistent intervals will significantly reduce system disturbances or sudden module failure. Regular preventive maintenance also ensures that problems are caught earlier, resulting in reductions in unscheduled downtime and in the cost and frequency of repairs. To demonstrate how well preventive maintenance works, Table 1 and Figure 1 show how plates and tailing factor improve when failed injector seals are replaced. Figure 2 captures the sort of irregular baseline that can result from leaking seals.

Enlarge

Enlarge

Figure 1. Injector seat failure – before (left) and after (right) seal replacement.

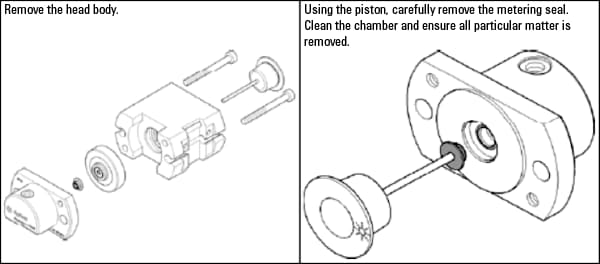

Figure 2. Schematic of irregular baseline noise that could be caused by leaking seals.

Enlarge

Enlarge

Figure 3. Easy access to serviceable parts in an Agilent autosampler.

Before |

After |

||

|---|---|---|---|

Plates |

USP TF (5%) |

Plates |

USP TF (5%) |

2,235 |

1.72 |

3,670 |

1.45 |

3,491 |

1.48 |

10,457 |

1.09 |

5,432 |

1.15 |

10,085 |

1.00 |

Table 1. Plates and tailing factor improve after rotor and isolation seals are replaced

Get everything you need in one handy kit

Agilent produces a comprehensive range of preventative maintenance kits that contain all the parts you need to keep pumps, autosamplers, and detectors operating at peak efficiency. Agilent preventive maintenance kits help to guarantee peak performance of your LC system at all times. These kits contain all of the components you need, including seals, frits or stators, fittings and connections for LC systems and applications.

With these kits, you can access all the affected areas of standard Agilent LC systems and carry out preventive maintenance yourself. Each part of the module that requires maintenance is easily accessible – and detailed drawings show how to replace a part. For example, Figure 3 is an exploded diagram of an Agilent autosampler module, complete with instructions on how to access the parts to be cleaned or replaced.

If, however, you would prefer to have someone else handle your preventive maintenance tasks, Agilent engineers are always available to do the work for you. But whatever you choose to do, Agilent has the preventive maintenance kit you need to ensure the job is done right. Here’s a sampling of available options:

Agilent pump kits include all the fittings, tubing, valves, seals, and other components required to keep pumps operating efficiently without the leaks and pressure fluctuations that can damage columns.

Agilent autosampler kits contain all the seals, needle seats, cartridges, and other components necessary to prevent loss of valuable samples.

Agilent detector kits provide the windows, gaskets, screw kits, and rings necessary for VWD equipment, with options for standard, micro, semi-micro, and high-pressure flow cells. DAD/MWD kits provide a range of options for different capacity flow cells and include all the ferrules, seals, wrenches, and torque adaptors required to deliver excellent performance in DAD/MWD applications.

Procedure |

Typical frequency |

|---|---|

Change needle/needle seat |

60,000 needle into seat |

Change metering seal |

30,000 injections |

Change peristaltic pump cartridge |

3,000 hours on time |

Change pump rotor seal |

30,000 injections |

Table 2. Maintenance overview for an Agilent 1260 Infinity Bio-inert High-Performance Autosampler.

Set up your own maintenance schedule. It’s easy

User manuals for each module provide recommendations on when parts should be exchanged and how parts can be ordered. The manuals include overviews, which can be used as a basis for establishing maintenance schedules to meet your lab’s needs and operating practice. Table 2 shows an example of such an overview. In the case of this bio-inert autosampler, the maintenance tasks can be easily done without opening the main cover.

Count on Agilent service and support for peak performance

Agilent preventive maintenance kits are designed to keep your LC system running at peak performance, making it easier to perform regular maintenance and helping you to catch potential problems before they become serious and expensive to rectify.

That’s just the beginning of what Agilent can do to help you maintain your valuable equipment. Agilent also provides a sophisticated array of self-service and self-help solutions that includes up-to-date documentation and software utility downloads covering many applications. So don’t procrastinate any longer. Get the most from your Agilent equipment today with our expertise and support that is just a call or click away.

>> Update My Profile | Subscribe to Access Agilent | Article Directory